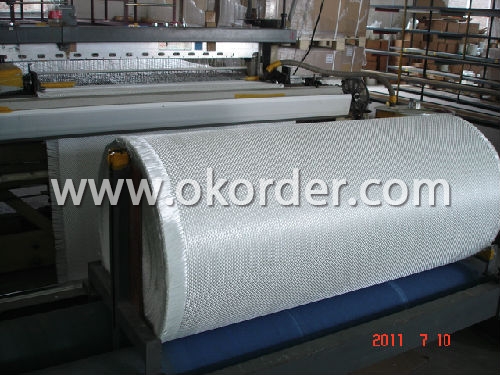

Ewr400 Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications OF EWR400

1. Low Fuzz,dirt,impurity and other stains.

2. Fast wet-out.

3. Even thickness

4.Good covering

5.Passed ISO9001,ISO14001

Characteristics of EWR400

Woven Roving is a high –performance reinforcement widely used in hand lay-up and machanical production

1) Good moldability & drapability

2) High strength

3) Excellent rollout characteristics

4) Fast wet -out

Application OF EWR400

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: How does fiberglass fabric perform in high humidity environments?

- Fiberglass fabric performs well in high humidity environments. It is resistant to moisture absorption, which helps maintain its structural integrity and prevents it from becoming weak or deformed. Additionally, fiberglass is not affected by mold or mildew growth, making it a durable and reliable choice even in humid conditions.

- Q: Can fiberglass fabric be used for reinforcement in aerospace structures?

- Yes, fiberglass fabric can be used for reinforcement in aerospace structures. It is lightweight, has high tensile strength, and offers good resistance to heat and corrosion. These properties make it suitable for applications such as reinforcing composite materials used in aircraft components, spacecraft, and satellites.

- Q: Are fiberglass fabrics suitable for use in the telecommunications industry?

- Fiberglass fabrics are indeed suitable for utilization in the telecommunications sector. They possess various advantages that render them perfect for this industry. Firstly, their strength and durability are well-known, enabling them to endure severe environmental conditions such as extreme temperatures, moisture, and UV exposure. Consequently, the telecommunications equipment, including antennas and cables, remains safeguarded and functions optimally over a prolonged duration. Moreover, fiberglass fabrics exhibit outstanding electrical insulation properties. This is of utmost importance in the telecommunications field as it prevents interference and signal loss, ensuring the transmission of clear and dependable signals. Furthermore, these fabrics possess a low dielectric constant and loss tangent, which further aids in minimizing signal attenuation. Additionally, fiberglass fabrics are lightweight and flexible, facilitating easy handling and installation. This proves particularly advantageous in the telecommunications industry, allowing for efficient and cost-effective equipment and infrastructure installation. Furthermore, their remarkable resistance to chemicals, corrosion, and fire makes fiberglass fabrics exceedingly reliable and secure for use in telecommunications equipment. This resistance guarantees the equipment's durability and reliability, thereby reducing maintenance and replacement expenses. In conclusion, the combination of high strength, durability, electrical insulation properties, lightweight nature, and resistance to chemicals and fire makes fiberglass fabrics highly appropriate for the telecommunications industry. They offer the necessary protection, reliability, and performance required for efficient and effective telecommunications operations.

- Q: What are the different coating options available for fiberglass fabric?

- There are several coating options available for fiberglass fabric. These coatings are designed to enhance the fabric's properties and make it suitable for various applications. 1. Silicone Coating: Silicone coating provides excellent heat resistance and can withstand high temperatures. It also offers good chemical resistance, making it suitable for applications in industries such as aerospace, automotive, and insulation. 2. Polyurethane Coating: Polyurethane coating provides a durable and flexible finish to fiberglass fabric. It offers good abrasion resistance, waterproofing, and UV stability. This coating is commonly used in applications like outdoor covers, tents, and awnings. 3. PTFE Coating: PTFE (Polytetrafluoroethylene) coating is known for its non-stick properties and high resistance to chemicals, heat, and weathering. It provides excellent electrical insulation and low friction properties. PTFE coated fiberglass fabric is commonly used in applications such as conveyor belts, release sheets, and insulation. 4. Acrylic Coating: Acrylic coating provides a smooth finish and enhances the fabric's durability and strength. It offers good resistance to UV rays, mildew, and abrasion. This coating is commonly used in applications like marine covers, outdoor furniture, and bags. 5. Neoprene Coating: Neoprene coating provides excellent resistance to oil, chemicals, and weathering. It also offers good flame resistance and flexibility. This coating is commonly used in applications such as protective clothing, gloves, and industrial curtains. 6. Vinyl Coating: Vinyl coating provides a waterproof and durable finish to fiberglass fabric. It offers good resistance to UV rays, abrasion, and chemicals. This coating is commonly used in applications like outdoor furniture, truck covers, and pool liners. These are just a few examples of the different coating options available for fiberglass fabric. The choice of coating depends on the specific requirements of the application, such as heat resistance, chemical resistance, flexibility, and durability.

- Q: Is fiberglass fabric suitable for use in electrical insulation tapes?

- Indeed, fiberglass fabric proves to be appropriate for implementation within electrical insulation tapes. Its remarkable electrical insulation properties and ability to endure elevated temperatures make it particularly well-suited for situations necessitating electrical insulation. Its resistance to heat, chemicals, and moisture guarantees enduring safeguarding for electrical components. Furthermore, fiberglass fabric's flexibility and ease of manipulation facilitate simple application onto diverse surfaces. All in all, fiberglass fabric stands as a dependable and efficient material choice for electrical insulation tapes.

- Q: How does fiberglass fabric perform in weight-to-strength ratio?

- Fiberglass fabric performs exceptionally well in terms of weight-to-strength ratio. It is known for its high strength despite being lightweight, making it an ideal material for various applications where strength is crucial, such as aerospace, automotive, and construction industries.

- Q: Is fiberglass fabric resistant to chemicals in agricultural applications?

- Yes, fiberglass fabric is generally resistant to chemicals in agricultural applications. It is known for its excellent chemical resistance, making it suitable for use in agricultural settings where exposure to various chemicals and fertilizers is common.

- Q: How is fiberglass fabric used in the production of thermal curtains?

- Fiberglass fabric is used in the production of thermal curtains as it possesses excellent insulating properties. It is often incorporated as a lining or layer within the curtain to increase its thermal efficiency. The fiberglass fabric helps to trap air pockets, preventing heat transfer between the inside and outside of the room. This insulation feature helps to keep the room warm in winters and cool in summers, making it an ideal choice for thermal curtains.

- Q: Can fiberglass fabric be used for reinforcement in mining tanks?

- Indeed, the utilization of fiberglass fabric is viable for reinforcing mining tanks. Recognized for its remarkable robustness and longevity, fiberglass fabric proves to be apt for an array of industrial uses, including the fortification of tanks. Its ability to resist corrosion renders it an optimal selection for mining tanks, withstanding the detrimental impact of harsh chemicals and abrasive substances frequently encountered in mining endeavors. Moreover, fiberglass fabric possesses a lightweight composition and effortless maneuverability, facilitating convenient installation and maintenance procedures. Consequently, the incorporation of fiberglass fabric for reinforcing mining tanks enhances their structural integrity and extends their lifespan, guaranteeing steadfast and effective performance throughout mining operations.

- Q: Is fiberglass fabric suitable for use in filtration systems?

- Yes, fiberglass fabric is suitable for use in filtration systems. It is commonly used in various industries, including air and liquid filtration, due to its excellent filtration properties, high temperature resistance, and durability. The tightly woven structure of fiberglass fabric allows it to effectively trap and remove particles, ensuring efficient filtration.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Above US$20 Million |

| Main Markets | Mid East;Western Europe;North America:South American |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 400,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | Average |

| Product Price Range | OEM Service Offered;Design Service Offered |

Send your message to us

Ewr400 Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords