All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

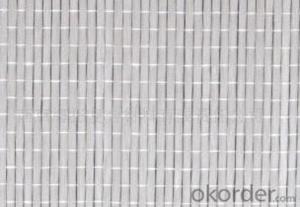

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

What are the health risks associated with fiberglass?

Exposure to fiberglass can lead to various health risks, including skin irritation, respiratory issues such as coughing and difficulty breathing, and eye irritation. In some cases, prolonged exposure or inhalation of fiberglass particles may cause more severe conditions such as lung diseases or cancer. It is important to take necessary precautions when working with or around fiberglass to minimize these risks.

What are the different types of fiberglass laminates?

There are several different types of fiberglass laminates, including woven fiberglass, chopped strand mat (CSM), unidirectional fiberglass, and hybrid laminates. Woven fiberglass laminates consist of interlaced fibers and are commonly used in applications that require strength and flexibility. CSM laminates are made up of randomly oriented chopped strands held together with a binder, offering good strength and impact resistance. Unidirectional fiberglass laminates have fibers oriented in a single direction, providing excellent strength in that specific direction. Hybrid laminates combine fiberglass with other materials like carbon fiber or Kevlar to enhance specific properties such as stiffness or impact resistance.

Can fiberglass supply be used for resin infusion?

Yes, fiberglass supply can be used for resin infusion. Resin infusion is a process in which resin is drawn into a dry fiberglass fabric using vacuum pressure. Fiberglass supply, such as dry fiberglass fabric or pre-preg materials, can be used as the reinforcement in resin infusion.

What are the different types of fiberglass fillers?

There are several types of fiberglass fillers available, including chopped strand mat, fiberglass cloth, fiberglass tape, and fiberglass filler paste. These fillers are used to reinforce and repair fiberglass surfaces, providing strength and durability.

What are the different curing methods for fiberglass?

There are several different curing methods for fiberglass, including room temperature curing, heat curing, and UV curing. Room temperature curing involves allowing the fiberglass to cure naturally at room temperature over a period of time, usually several hours or days. Heat curing involves applying heat to accelerate the curing process, typically using ovens or heat lamps. UV curing utilizes ultraviolet light to cure the fiberglass, which can be achieved through exposure to sunlight or using specialized UV lamps.

Wholesale Fiberglass Supply from supplier in Nigeria

With our dedication to customer satisfaction, we strive to deliver high-quality Fiberglass Supply products that meet international standards. Our team of experienced professionals are committed to providing reliable technical support and guidance throughout the procurement process. Whether you require Fiberglass Supply products for construction, industrial, or other applications, we have the expertise to deliver tailored solutions to meet your specific needs. We understand the unique challenges of the Nigerian market and are well-equipped to navigate them, ensuring timely delivery and competitive pricing. Trust us to be your dependable supplier of Fiberglass Supply products in Nigeria.

Hot Search

- Fiberglass Chopped Strand in Czech Republic

- Fiberglass Mesh Cloth in Portugal

- Composite Pipes in Germany

- FRP Pultrusion Profiles in Georgia

- Fiberglass Mat Tissue in Senegal

- Fiberglass Fabrics in Greece

- Fiberglass Mesh in Philippines

- Composite Tank in Tonga

- Fiberglass Mesh tape in Croatia

- Polymer in Nauru