All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

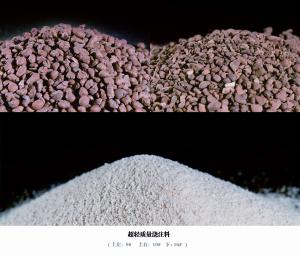

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining EAF water-cooled panels?

Yes, monolithic refractories can be used for lining EAF water-cooled panels. Monolithic refractories are suitable for high-temperature applications and can provide excellent thermal and chemical resistance, making them an ideal choice for lining the water-cooled panels in an Electric Arc Furnace (EAF). Additionally, monolithic refractories offer ease of installation and can be tailored to fit specific shapes and sizes, ensuring a tight and efficient lining for the EAF water-cooled panels.

How do monolithic refractories compare to ceramic fibers in terms of insulation properties?

Monolithic refractories generally have lower insulation properties compared to ceramic fibers. While monolithic refractories offer excellent strength and resistance to thermal shock, they are denser and have higher thermal conductivity, resulting in reduced insulation efficiency. On the other hand, ceramic fibers are lightweight, have low thermal conductivity, and provide superior insulation performance, making them a preferred choice for high-temperature insulation applications.

How do monolithic refractories provide resistance to chemical corrosion in acid tanks?

Monolithic refractories provide resistance to chemical corrosion in acid tanks by forming a dense and impermeable lining that acts as a barrier between the corrosive acid and the tank's structure. This lining is typically composed of materials that are resistant to the specific chemicals present in the acid, preventing them from penetrating and deteriorating the tank. Additionally, monolithic refractories have high chemical stability, meaning they do not react with the acid, further enhancing their resistance to corrosion.

What are the recommended installation techniques for monolithic refractories in rotary dryers?

The recommended installation techniques for monolithic refractories in rotary dryers involve thorough surface preparation, proper mixing and placement of refractory materials, appropriate curing and drying procedures, and regular maintenance and inspection to ensure the longevity and efficiency of the refractory lining.

How do monolithic refractories handle high-temperature basic attack?

Monolithic refractories handle high-temperature basic attack by utilizing materials that are resistant to basic chemical reactions and can withstand extreme temperatures. They are typically made from a combination of refractory aggregates, binders, and additives that provide excellent resistance to basic slags and alkali metals, preventing damage and degradation of the refractory lining. Additionally, the composition and design of monolithic refractories are tailored to withstand thermal shock, erosion, and other forms of wear and tear caused by high-temperature basic attack.

Wholesale Monolithic Refractories from supplier in Nigeria

With our commitment to quality and customer satisfaction, we ensure that our Monolithic Refractories products meet the highest standards. Our team of experienced professionals is available to provide technical support and guidance throughout the entire project, from product selection to installation.

We understand the unique challenges and requirements of the Nigerian market, and we have tailored our services to meet these needs. Whether you are in the steel, cement, petrochemical, or any other industry requiring Monolithic Refractories, we have the right solutions for you.

In addition to sales and technical support, we also offer competitive pricing and timely delivery to ensure that your projects stay on schedule and within budget. Our strong partnership with CNBM allows us to leverage their vast resources and global network to provide you with the best products at the most competitive prices.

At our company, we believe in building long-term relationships with our customers. We strive to exceed your expectations and provide you with the highest level of service and support. Trust us to be your reliable partner for all your Monolithic Refractories needs in Nigeria. Contact us today for sales, quotes, and technical support services.

We understand the unique challenges and requirements of the Nigerian market, and we have tailored our services to meet these needs. Whether you are in the steel, cement, petrochemical, or any other industry requiring Monolithic Refractories, we have the right solutions for you.

In addition to sales and technical support, we also offer competitive pricing and timely delivery to ensure that your projects stay on schedule and within budget. Our strong partnership with CNBM allows us to leverage their vast resources and global network to provide you with the best products at the most competitive prices.

At our company, we believe in building long-term relationships with our customers. We strive to exceed your expectations and provide you with the highest level of service and support. Trust us to be your reliable partner for all your Monolithic Refractories needs in Nigeria. Contact us today for sales, quotes, and technical support services.

Hot Search

- Monolithic Refractories in Guyana

- Ceramic Fiber Products in Bengal

- Refractory Bricks in Malaysia

- Raw Materials For Refractory in America

- Refractory Bricks in Oman

- Refractory Bricks in Austria

- Refractory Bricks in Philippines

- Monolithic Refractories in Haiti

- Raw Materials For Refractory in Serbia

- Ceramic Fiber Products in Norway