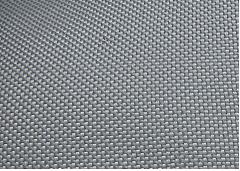

Biaxial Fiberglass Fabric for Surfboard

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Fabrics for surfboard:

The Fiberglass Fabrics for surfboard is a kind of alkali-free glass fiber fabrics produced by utilizing abroad advanced technology and equipment. By means of a surface treatment it has excellent electro-insulation property and workability. It is used mainly in printed circuit boards, and is also used as base materials for computers and home electro-devices.

The Fiberglass Fabrics for surfboard is weaved of high quality C-glass fibers or E-glass fibers.

The excellent properties of Fiberglass Fabrics for surfboard:

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of Fiberglass Fabrics for surfboard:

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

Packing of Fiberglass Fabrics for surfboard:

The Fiberglass fabric for surfboard is wrapped on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

- Q: Is fiberglass fabric suitable for making backpacks and bags?

- Yes, fiberglass fabric is suitable for making backpacks and bags. It is known for its exceptional strength, durability, and resistance to tearing or puncturing. Additionally, fiberglass fabric is lightweight and has excellent insulation properties, making it an ideal choice for outdoor gear like backpacks and bags.

- Q: Can fiberglass fabric be used for making tablecloths?

- Typically, fiberglass fabric is not employed in the creation of tablecloths. Such a fabric is renowned for its durability, strength, and resistance to heat, rendering it more appropriate for usage in insulation, construction materials, or protective clothing. Conversely, tablecloths are usually fashioned from fabrics that possess qualities like softness, lightweightness, and ease of cleaning, such as cotton, linen, polyester, or blends thereof. These fabrics provide a pleasant and visually pleasing surface for dining and are better suited for the purpose of tablecloths.

- Q: Can fiberglass fabric be used for making insulation boards or panels?

- Yes, fiberglass fabric can be used for making insulation boards or panels. Fiberglass fabric is a versatile material that is often used for insulation purposes due to its excellent thermal properties. It is made of fine glass fibers woven together to create a strong and durable fabric. When used in insulation boards or panels, fiberglass fabric helps to trap air and prevent heat transfer, thus providing effective insulation. Additionally, it is lightweight, easy to handle, and resistant to moisture, making it a suitable choice for various applications where insulation is required, such as in buildings, industrial equipment, and automotive components. Overall, fiberglass fabric is a reliable and efficient material for making insulation boards or panels.

- Q: Can fiberglass fabric be used for making conveyor belts?

- Yes, fiberglass fabric can be used for making conveyor belts. It is a durable and lightweight material that offers high tensile strength and excellent resistance to abrasion and chemicals, making it suitable for conveyor belt applications in various industries.

- Q: What's the difference between glass fiber tape and fiberglass tape?

- One tape, one is the base material, no adhesive. Fiberglass is glass fiber.

- Q: Can fiberglass fabric be used for reinforcing plaster or stucco?

- Fiberglass fabric, when used for reinforcing plaster or stucco, can significantly enhance the strength and stability of the surfaces. This durable and robust material is commonly employed in construction projects to prevent cracks and bolster the overall durability of plaster or stucco. Typically, the fiberglass fabric is applied to the surface prior to the application of plaster or stucco, ensuring an even distribution of stress and minimizing the likelihood of cracking or crumbling. Moreover, fiberglass fabric possesses resistance against both moisture and weathering, rendering it an ideal choice for exterior applications, where plaster or stucco may face harsh environmental conditions. Ultimately, the utilization of fiberglass fabric in reinforcing plaster or stucco contributes to the improved structural integrity and longevity of the final surfaces.

- Q: Can fiberglass fabric be used for insulation in construction projects?

- Yes, fiberglass fabric can be used for insulation in construction projects. Fiberglass fabric is made from woven glass fibers, which have excellent thermal insulation properties. It is commonly used as an insulation material in walls, roofs, and floors to prevent heat transfer and improve energy efficiency in buildings. The fabric is lightweight, flexible, and easy to install, making it a popular choice for construction projects. Additionally, fiberglass fabric is resistant to fire, moisture, and chemicals, making it a durable and long-lasting insulation material.

- Q: Can fiberglass fabrics be used for reinforcement in concrete structures?

- Yes, fiberglass fabrics can be used for reinforcement in concrete structures. Fiberglass fabrics are made from woven or knitted fibers of glass, which provide high strength and durability. When embedded in concrete, fiberglass fabrics can help to improve the tensile strength and crack resistance of the concrete. They are commonly used as an alternative to traditional steel reinforcement in certain applications. Fiberglass fabrics are lightweight, non-corrosive, and easy to handle, making them a suitable choice for various concrete structures such as walls, slabs, beams, and columns. Additionally, fiberglass fabrics can also offer advantages in terms of thermal and electrical insulation, as well as resistance to chemicals. However, it is important to note that the selection and design of reinforcement materials should be based on specific project requirements and engineering considerations.

- Q: Is fiberglass fabric suitable for use in protective gloves?

- Yes, fiberglass fabric can be suitable for use in protective gloves. Fiberglass is known for its high strength and heat resistance properties, making it an ideal material for gloves used in industries that involve high temperatures or exposure to flames. It provides excellent protection against heat, chemicals, and abrasions. Additionally, fiberglass fabric is lightweight and flexible, allowing for ease of movement and dexterity, which is crucial in many work environments. However, it is important to note that fiberglass can cause skin irritation or allergic reactions in some individuals, so proper precautions should be taken, such as wearing a liner glove, to minimize direct contact with the skin.

- Q: Is fiberglass fabric resistant to punctures?

- Fiberglass fabric exhibits puncture resistance, showcasing its durability and strength. This material is renowned for its ability to withstand punctures and tears, making it a preferred choice in various fields. For instance, it finds extensive usage in protective clothing, automotive components, and insulation materials, where puncture resistance is crucial. The woven structure of fiberglass fabric adds an extra layer of robustness, effectively preventing punctures. However, it is worth noting that despite its high resistance, fiberglass fabric is not entirely impervious to punctures. Depending on the object's force and sharpness, it is still possible to puncture fiberglass fabric, albeit less likely when compared to alternative materials.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Biaxial Fiberglass Fabric for Surfboard

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords