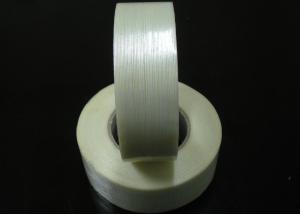

1708 Biaxial Fiberglass Tape

1708 Biaxial Fiberglass Tape Related Searches

1708 Fiberglass Cloth 1708 Fiberglass Roll Fibreglass Mesh Tape Bondstrand Fiberglass Pipe Fibreglass Pipes High Pressure Fiberglass Pipe Car Fiberglass Fiberglass Pipe Repair Fiberglass Thermal Insulation Fiberglass Yarn Glass Foil Tape Fiberglass Temperature Resistance Fiberglass Fabric Fiberglass Filament Winding Machine Fiberglass Pipe Shaver Fibreglass Fabric Two Sided Foam Tape Fiberglass Woven Double Sided Carbon Tape Binding Tape Thermally Conductive Double Sided Tape Fiberglass Roofing Tissue Industrial Double Sided Adhesive Tape Double Sided Foam Tape Fiberglass Woven Fabric Conductive Aluminum Tape Double Sided Cellophane Tape Protective Film Tape Stained Glass Copper Foil Tape Fiberglass Roving1708 Biaxial Fiberglass Tape Supplier & Manufacturer from China

1708 Biaxial Fiberglass Tape is a high-quality product that is widely used in various industries due to its exceptional strength and durability. This tape is made from fiberglass yarns that are coated with a special adhesive, making it an ideal choice for applications that require high tensile strength and resistance to temperature extremes. The tape is designed to provide excellent adhesion to various surfaces, ensuring a secure bond in a variety of environments.The 1708 Biaxial Fiberglass Tape is commonly used in construction, automotive, and marine applications, where its ability to withstand harsh conditions and resist corrosion is highly valued. It is also popular in the aerospace industry for its lightweight properties and ability to maintain its integrity under extreme temperatures. This versatile tape can be used for sealing joints, reinforcing structures, and providing protection against abrasion and impact damage.

Okorder.com is a reputable wholesale supplier of 1708 Biaxial Fiberglass Tape, offering a large inventory of this essential product to customers around the world. With a commitment to quality and customer satisfaction, Okorder.com ensures that the tape is available in various widths and lengths to meet the specific needs of each project. By partnering with Okorder.com, businesses can benefit from competitive pricing and reliable supply, ensuring that they have access to the materials they need to complete their projects successfully.

Hot Products