All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

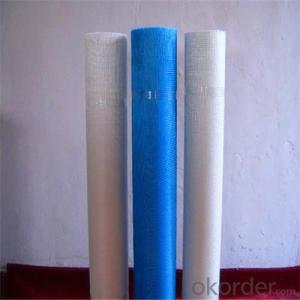

- - Fiberglass Mesh Cloth

- - Composite Pipes

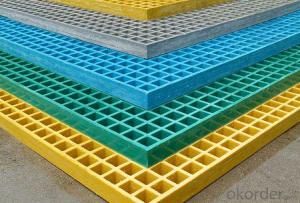

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

What are some common surface preparation techniques for fiberglass?

Some common surface preparation techniques for fiberglass include sanding, washing with soap and water, using a solvent cleaner, and applying a primer before painting or applying a new layer of fiberglass.

What are the advantages of using fiberglass?

One advantage of using fiberglass is its high strength-to-weight ratio, making it a lightweight yet durable material. Additionally, fiberglass is highly resistant to corrosion, chemicals, and extreme temperatures, making it suitable for various applications such as construction, automotive, and aerospace industries. It is also an excellent electrical insulator and has good sound insulation properties. Furthermore, fiberglass is relatively easy to mold into complex shapes, allowing for design flexibility and customization.

How is fiberglass used in aerospace industry?

Fiberglass is commonly used in the aerospace industry for various applications. It is used to manufacture lightweight, strong, and durable components such as aircraft fuselages, wings, and fairings. The high strength-to-weight ratio of fiberglass makes it an ideal material for improving fuel efficiency and reducing overall aircraft weight. Additionally, fiberglass is also used in insulation, radomes, and other protective structures in aerospace vehicles.

How is fiberglass used in the production of wastewater treatment filters?

Fiberglass is commonly used in the production of wastewater treatment filters due to its high durability, corrosion resistance, and excellent filtration properties. It is often used as the main material for the filter media, where it efficiently traps solid particles, impurities, and contaminants from wastewater. Additionally, fiberglass filters can be easily cleaned and have a long lifespan, making them ideal for the demanding conditions of wastewater treatment plants.

What are the different impact resistance options available for fiberglass supply?

There are several impact resistance options available for fiberglass supply, including incorporating additives such as impact modifiers or reinforcements like carbon fibers or Kevlar. These options can enhance the strength and durability of fiberglass materials, making them more resistant to impacts and reducing the risk of damage or breakage.

Wholesale Fiberglass Supply from supplier in Maldives

Our company is located in the beautiful Maldives and specializes in supplying high-quality fiberglass products. We are a trusted subsidiary of the well-known Fortune Global 500 company CNBM, which ensures that our services are comprehensive and reliable. We offer sales, quotations, and technical support exclusively in the Maldives region.

Our goal is to provide you with a seamless procurement experience for all your fiberglass supply needs. We have an extensive range of fiberglass products to cater to a diverse clientele in the Maldives. With our commitment to excellence and market expertise, gained through years of operation in this region, we can offer valuable insights and support for your projects.

No matter what industry you are in, whether it is construction, manufacturing, or any other field, we have the expertise to meet your specific requirements for fiberglass supply. Our team is dedicated to providing exceptional customer service. We understand the importance of timely delivery and competitive pricing, and we strive to exceed your expectations in every aspect of our service.

Choose us as your trusted fiberglass supply supplier in the Maldives and experience our commitment to quality, reliability, and customer satisfaction. Contact us today and let us assist you in making your projects a resounding success.

Our goal is to provide you with a seamless procurement experience for all your fiberglass supply needs. We have an extensive range of fiberglass products to cater to a diverse clientele in the Maldives. With our commitment to excellence and market expertise, gained through years of operation in this region, we can offer valuable insights and support for your projects.

No matter what industry you are in, whether it is construction, manufacturing, or any other field, we have the expertise to meet your specific requirements for fiberglass supply. Our team is dedicated to providing exceptional customer service. We understand the importance of timely delivery and competitive pricing, and we strive to exceed your expectations in every aspect of our service.

Choose us as your trusted fiberglass supply supplier in the Maldives and experience our commitment to quality, reliability, and customer satisfaction. Contact us today and let us assist you in making your projects a resounding success.