All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of aluminum coils in the renewable energy industry for solar tracking systems?

Aluminum coils play a crucial role in the renewable energy industry for solar tracking systems as they are used to construct the framework and structural components of solar tracking systems. These coils are lightweight, durable, and corrosion-resistant, making them ideal for withstanding harsh weather conditions and ensuring the longevity of solar tracking systems. Additionally, aluminum coils provide the necessary strength and flexibility to support the movement and rotation of solar panels, maximizing the efficiency of solar energy generation.

How are aluminum coils used in the automotive industry for aluminum wheels?

Aluminum coils are used in the automotive industry for aluminum wheels as they are the primary raw material for manufacturing these wheels. The aluminum coils are first processed and shaped into the desired wheel design. They are then forged, machined, and coated to enhance their strength, durability, and appearance. The use of aluminum coils allows for lightweight wheels, which improves fuel efficiency and overall vehicle performance. Additionally, aluminum wheels offer better heat dissipation, reducing the risk of brake fade and increasing safety on the road.

What is the role of aluminum coils in the aerospace fuel tank industry?

Aluminum coils serve a crucial role in the aerospace fuel tank industry as they are used for manufacturing lightweight and durable fuel tanks. These coils are specifically chosen for their high strength-to-weight ratio, corrosion resistance, and thermal conductivity properties. They are formed into various shapes and sizes to construct fuel tanks that can withstand the extreme conditions of flight, ensuring the safe storage and transportation of fuel in aircraft.

How do you determine the appropriate coil thickness for electrical conductivity?

The appropriate coil thickness for electrical conductivity is determined by considering factors such as the desired current carrying capacity, the material properties of the coil, and the application requirements. Thicker coils usually have lower resistance and higher current carrying capacity, but they may also be more expensive and bulkier. It is important to strike a balance between these factors to achieve optimal conductivity while meeting the specific requirements of the electrical application.

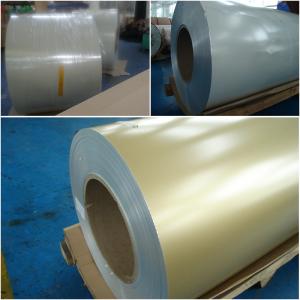

Wholesale Aluminum Coils from supplier in Maldives

Our team is committed to delivering high-quality Aluminum Coils that meet the specific requirements of our clients in the Maldives. We understand the importance of timely delivery and offer efficient logistics and shipping services to ensure that our products reach our customers on time.

In addition to our sales services, we also provide accurate and competitive quotations for Aluminum Coils products. Our experienced team is always ready to assist our clients in selecting the right products for their projects and provide technical support whenever needed.

Being a subsidiary of CNBM, a renowned Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer comprehensive procurement services, ensuring that our customers in the Maldives receive the best quality Aluminum Coils at the most competitive prices.

We take pride in our market expertise in the Maldives and have successfully completed numerous projects in various industries. Our experience allows us to understand the unique challenges and requirements of different sectors, enabling us to provide tailored solutions to our clients.

Whether you need Aluminum Coils for construction, manufacturing, or any other application, we have a wide range of products to meet your specific needs. Our commitment to quality, reliability, and customer satisfaction sets us apart as a trusted supplier of Aluminum Coils in the beautiful Maldives.

In addition to our sales services, we also provide accurate and competitive quotations for Aluminum Coils products. Our experienced team is always ready to assist our clients in selecting the right products for their projects and provide technical support whenever needed.

Being a subsidiary of CNBM, a renowned Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer comprehensive procurement services, ensuring that our customers in the Maldives receive the best quality Aluminum Coils at the most competitive prices.

We take pride in our market expertise in the Maldives and have successfully completed numerous projects in various industries. Our experience allows us to understand the unique challenges and requirements of different sectors, enabling us to provide tailored solutions to our clients.

Whether you need Aluminum Coils for construction, manufacturing, or any other application, we have a wide range of products to meet your specific needs. Our commitment to quality, reliability, and customer satisfaction sets us apart as a trusted supplier of Aluminum Coils in the beautiful Maldives.