High Quality Fiberglass Fabrics - E Glass Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

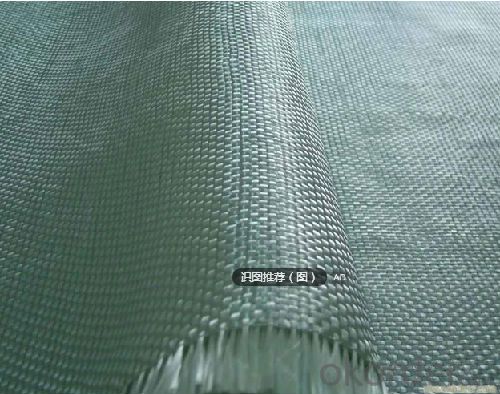

E Glass Fiber Fabrics are bidirectional fabric made by interweaving direct rovings.

E Glass Fiber Fabrics are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E Glass Fiber Fabrics are a high performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Product Features:

● Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

● Densely aligned fibers, resulting in high dimensional stability and making handling easy

● Good moldability, fast and complete wet out in resins, resulting in high productivity

● Good mechanical properties and high strength of parts

Product Specifications:

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Is fiberglass fabric suitable for use in geotextiles?

- Fiberglass fabric is indeed suitable for use in geotextiles. It possesses remarkable strength and durability, making it an ideal choice for situations that necessitate geotextiles. Geotextiles are employed in a variety of civil engineering projects to provide stability, separation, filtration, and reinforcement. Fiberglass fabric is capable of effectively fulfilling these functions due to its exceptional tensile strength, resistance to chemicals, and ability to withstand high temperatures. Moreover, it offers significant resistance to biological decay, ensuring its longevity as a geotextile material. Being non-biodegradable, it will maintain its integrity over time, guaranteeing long-term performance and stability. Consequently, fiberglass fabric emerges as a suitable and dependable option for geotextile applications.

- Q: Can fiberglass fabric be used for reinforcement in food processing tanks?

- Using fiberglass fabric for reinforcement in food processing tanks is not recommended. This is due to the presence of small fibers in fiberglass that can detach and contaminate the food products. Consumption of these fibers can be unsafe and may pose health risks. Thus, it is crucial to utilize food-grade materials that are specially designed for food processing tanks in order to guarantee the safety and quality of the processed food items.

- Q: Can fiberglass fabric be painted?

- Yes, fiberglass fabric can be painted. However, it is important to properly prepare the surface before painting to ensure good adhesion. This typically involves cleaning the fabric to remove any dirt, dust, or oils, and then applying a primer specifically designed for use on fiberglass surfaces. Once the primer has dried, you can proceed to paint the fiberglass fabric with a suitable paint. It is important to use a paint that is compatible with the type of fiberglass fabric you are working with, as well as one that is designed for the specific application you have in mind (e.g., indoor or outdoor use). Additionally, it is recommended to use multiple thin coats of paint rather than one thick coat to achieve the best results.

- Q: How is fiberglass fabric used in the production of fire-resistant blankets?

- Due to its exceptional fire-resistant properties, fiberglass fabric plays a crucial role in the production of fire-resistant blankets. This fabric is made from woven glass fibers, which possess high resistance to heat and flames. To enhance its fire-resistant capabilities, fiberglass fabric is initially coated with a fire-resistant material or treated with a fire-retardant chemical during the production process. This treatment ensures that the fabric can withstand high temperatures and prevent the spread of fire. By layering multiple sheets of fiberglass fabric together, thick and durable fire-resistant blankets are manufactured. These blankets are sewn or bonded together to create a single unit, offering maximum protection. When exposed to fire, fiberglass fabric acts as an insulator, reflecting heat and preventing its transfer to the other side of the blanket. This effectively suppresses the spread of flames and reduces the risks of burns and injuries. Moreover, fiberglass fabric is lightweight and flexible, allowing for easy handling and maneuverability during emergency situations. Consequently, fire-resistant blankets made with fiberglass fabric find wide application in industries such as firefighting, oil and gas, manufacturing, and construction. They serve to safeguard workers, equipment, and valuable assets from fire hazards. Overall, the utilization of fiberglass fabric in the production of fire-resistant blankets ensures a high level of protection against heat and flames, effectively mitigating fire-related risks.

- Q: Can fiberglass fabric be used for making luggage?

- Yes, fiberglass fabric can be used for making luggage. It provides strength, durability, and lightweight properties, making it an ideal material for creating sturdy and long-lasting luggage.

- Q: Can fiberglass fabric be used for making gaskets or seals?

- Indeed, the utilization of fiberglass fabric is viable for the production of gaskets and seals. Renowned for its superior potency and durability, fiberglass fabric emerges as an optimal material selection for applications pertaining to gaskets and seals. Its capacity to endure elevated temperatures, withstand chemical substances, and provide insulation properties renders it suitable for deployment across a diverse range of sectors, encompassing automotive, aerospace, and manufacturing. Moreover, the versatility of fiberglass fabric permits effortless cutting and molding into various shapes and sizes, tailored to meet the specific requirements of individual gaskets or seals. Overall, fiberglass fabric showcases commendable sealing capabilities, thereby establishing itself as a dependable option for fabricating gaskets and seals.

- Q: Can fiberglass fabric be used for insulation in nuclear power plants?

- Yes, fiberglass fabric can be used for insulation in nuclear power plants. Fiberglass is a commonly used material for insulation in various industries, including nuclear power plants. It offers several advantages such as excellent thermal resistance, fire resistance, and low thermal conductivity. These properties make it suitable for insulating equipment and components in nuclear power plants where high temperatures and potential fire hazards are present. Additionally, fiberglass is also resistant to moisture, chemicals, and radiation, which are significant considerations in the nuclear industry. However, it is important to note that the specific application and required safety standards should be taken into account when selecting and installing insulation materials in nuclear power plants.

- Q: Is fiberglass fabric resistant to rodents?

- Generally speaking, fiberglass fabric exhibits resistance to rodents. Rodents are not inclined to find the material appetizing, resulting in a decreased likelihood of them chewing or gnawing on it in comparison to materials like wood or plastic. This resistance explains why fiberglass fabric is a favored option for insulation in areas like attics and crawl spaces, where rodents are often present. Nevertheless, it is crucial to acknowledge that fiberglass fabric is not entirely impervious to rodents. In exceptional circumstances, rodents may still endeavor to chew or tunnel through the fabric if they possess a strong motivation or if the fabric sustains any form of damage or compromise.

- Q: Can fiberglass fabric be used for filtration?

- Indeed, filtration purposes can be achieved using fiberglass fabric. Renowned for its robustness, longevity, and resistance to chemicals, fiberglass fabric emerges as an optimal material for filtration applications. Its utilization is prevalent across sectors such as water treatment, oil and gas, pharmaceuticals, and food processing. Fiberglass fabric assumes the role of a filtering medium, proficiently eliminating impurities, solid particles, and contaminants from liquids or gases. Its intricate network of delicate fibers effectively ensnares and retains particles of diverse sizes, culminating in an efficacious filtration process. The paramount advantage of fiberglass fabric in filtration lies in its capacity to endure high temperatures. It exhibits resilience in extreme thermal conditions, rendering it suitable for scenarios necessitating the filtration of corrosive or hot fluids. Moreover, fiberglass fabric can be tailor-made to match specific filtration requisites. It can be subjected to coatings or treatments with a variety of substances to enhance filtration efficiency, augment chemical resistance, or confer water repellency. In summary, fiberglass fabric stands as a versatile material, proficiently employed for filtration purposes owing to its durability, temperature resistance, customization potential, and strength.

- Q: Can fiberglass fabric be used for making soundproofing materials?

- Yes, fiberglass fabric can be used for making soundproofing materials. Fiberglass is an excellent material for sound insulation due to its high density and ability to absorb sound waves. When used in the form of fabric, it can be applied as a layer or wrapped around surfaces to effectively reduce noise transmission. Fiberglass fabric is commonly used in the construction industry for creating sound barriers in walls, ceilings, and floors. It is also utilized in automotive and aerospace applications to minimize noise pollution. The fabric's ability to trap and absorb sound waves makes it an ideal choice for soundproofing materials. However, it is important to note that proper installation and additional layers may be required to achieve optimal soundproofing results.

Send your message to us

High Quality Fiberglass Fabrics - E Glass Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords