Fabric for Fiberglass - E-Glass Surfboards Fiberglass Fabric for Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

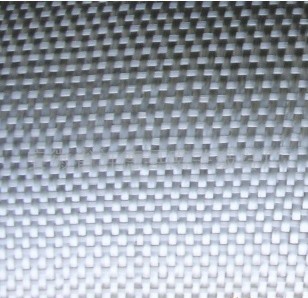

Introduction of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabric is weaved of high quality C-glass fibers or E-glass fibers.

Fiberglass fabric is a good construction material with the following excellent properties

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

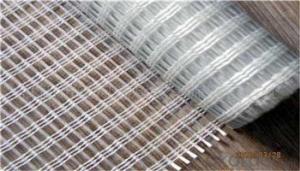

Packing of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabric is wound on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

Storage of E-glass Surfboards Fiberglass Fabric:

Store rolls in a cool, dry location

Protect rolls from weather and other damage.

- Q: Can fiberglass fabric be used for making carpet backing?

- Yes, fiberglass fabric can be used for making carpet backing. Fiberglass fabric is known for its strength, durability, and resistance to heat and moisture. These properties make it an ideal material for carpet backing as it provides stability and support to the carpet, helping it maintain its shape and structure. Additionally, fiberglass fabric is lightweight and flexible, making it easier to handle and install. It also offers good dimensional stability, preventing the carpet from stretching or shrinking over time. Overall, fiberglass fabric is a suitable choice for making carpet backing due to its strength, durability, and other beneficial properties.

- Q: Can fiberglass fabric be used for reinforcement in aerospace structures?

- Yes, fiberglass fabric can be used for reinforcement in aerospace structures. Fiberglass is a lightweight and high-strength material that offers excellent mechanical properties, such as high tensile strength and stiffness. It also has a low coefficient of thermal expansion, which is beneficial for aerospace applications where temperature changes can occur. Fiberglass fabric can be used as a reinforcement material in composite structures, where it is typically combined with a resin matrix, such as epoxy or polyester. The fabric is impregnated with the resin and then cured to form a rigid composite material. This composite material can be used to manufacture various aerospace components, such as aircraft wings, fuselage panels, and engine components. One of the advantages of using fiberglass fabric for aerospace reinforcement is its excellent corrosion resistance. Fiberglass does not rust or corrode like metals, making it suitable for applications in harsh environments, such as high-altitude flights or exposure to extreme weather conditions. Additionally, fiberglass is electrically non-conductive, which can be advantageous for aerospace structures where electrical insulation is necessary. Moreover, fiberglass fabric is relatively cost-effective compared to other reinforcement materials, such as carbon fiber. This makes it an attractive option for aerospace manufacturers who strive to balance performance and cost efficiency. However, it is important to note that the specific application and requirements of the aerospace structure should be considered when selecting the appropriate reinforcement material. While fiberglass fabric offers numerous advantages, other materials may be more suitable for certain applications that require even higher strength or specific properties.

- Q: Sofa three proofing fabric and 6 anti distinction

- Six cloth is a kind of fireproof, waterproof, moisture-proof, anti-corrosion, insect bites, radiation proof multifunctional cloth. Six cloth and its products is a kind of high technology, the reflectivity of infrared ray radiation wave was above 90%. The color pattern can be made into a variety of patterns, and has the special properties of flame in combustion next, also has good heat preservation and heat insulation.

- Q: Are fiberglass fabrics easy to sew or work with?

- Sewing or working with fiberglass fabrics is typically not an easy task due to their unique properties and characteristics. Unlike other textiles, fiberglass fabrics are incredibly durable and resistant to heat, fire, chemicals, and most environmental factors. These qualities make them perfect for insulation, protective clothing, and adding strength to composites. However, these same properties also make them challenging to sew or work with. The primary difficulty in sewing fiberglass fabrics lies in their stiffness and rigidity. Unlike conventional fabrics, fiberglass fabrics lack flexibility, which makes them challenging to handle and manipulate. Their inability to stretch also makes it difficult to shape or contour them to fit certain designs. This can create complications when attempting to sew complex or intricate patterns using fiberglass fabrics. Furthermore, the sharp and abrasive nature of fiberglass fibers can cause damage to traditional sewing machines, needles, and threads. The sharp edges of the fibers can quickly wear down needles and lead to thread breakage or fraying. This can result in frustration and inefficiency when working with fiberglass fabrics. To overcome these challenges, specialized techniques and equipment are often necessary when sewing or working with fiberglass fabrics. This may involve the use of heavy-duty sewing machines, specialized needles and threads, and taking precautions to protect oneself from potential health hazards associated with fiberglass fibers. In conclusion, although fiberglass fabrics offer excellent performance and durability in various applications, they are not as easy to sew or work with compared to traditional textiles. The stiffness, lack of flexibility, and abrasive nature of the fibers require the use of specialized techniques and equipment to successfully work with these fabrics.

- Q: Is fiberglass fabric resistant to chemicals in oil and gas industry?

- Indeed, in the realm of the oil and gas industry, chemicals pose no threat to fiberglass fabric. Renowned for its extraordinary chemical resistance qualities, fiberglass fabric proves to be apt for a multitude of industrial uses, particularly within the oil and gas sector. Its resistance spans across a broad spectrum of chemicals, encompassing acids, alkalis, solvents, and hydrocarbons, which are frequently encountered in this industry. Furthermore, fiberglass fabric also demonstrates resistance against elevated temperatures, fire, and UV radiation, thereby establishing itself as a resilient and dependable material option for deployment in this field.

- Q: Can fiberglass fabric be used for making signs and banners?

- Yes, fiberglass fabric can be used for making signs and banners. Fiberglass fabric is a versatile material that offers several advantages for this purpose. It is lightweight, durable, and resistant to both weather conditions and UV radiation. These properties make it suitable for outdoor applications, ensuring that signs and banners made from fiberglass fabric can withstand the elements and maintain their appearance for a long time. Additionally, fiberglass fabric can be easily printed on, allowing for vibrant and eye-catching designs. Its flexibility also enables it to be easily manipulated and shaped, making it a versatile choice for creating various sign and banner designs. Overall, fiberglass fabric is a reliable and effective material for making signs and banners due to its durability, weather resistance, and printability.

- Q: What are the potential health risks associated with handling fiberglass fabric?

- Handling fiberglass fabric can potentially pose several health risks. One of the main concerns is the possibility of skin irritation or allergic reactions. The tiny glass fibers in fiberglass fabric can cause irritation to the skin, leading to redness, itching, and rashes. Prolonged or repeated exposure to these fibers can also result in dermatitis, a condition characterized by inflammation of the skin. In addition to skin irritation, fiberglass fabric can also be harmful if inhaled. When the fabric is cut, sanded, or disturbed in any way, it releases small fibers into the air. Breathing in these fibers can irritate the respiratory system, causing coughing, wheezing, and shortness of breath. Over time, repeated exposure to fiberglass fibers may lead to more serious respiratory conditions such as bronchitis or even lung cancer. Furthermore, the small size of fiberglass fibers makes them difficult to see and remove from the body once they have been inhaled or come into contact with the skin. This can lead to long-term health risks as these fibers can become lodged in the lungs or other organs, causing chronic inflammation and scarring. To minimize the potential health risks associated with handling fiberglass fabric, it is important to take proper precautions. This includes wearing protective clothing such as gloves, long sleeves, and pants to prevent direct contact with the skin. Using a respirator or mask can help reduce the inhalation of fiberglass fibers. It is also crucial to work in a well-ventilated area or use exhaust fans to minimize the concentration of airborne fibers. Regularly cleaning and maintaining workspaces to remove any accumulated fibers is also recommended. Overall, while fiberglass fabric has numerous applications and benefits, it is important to be aware of the potential health risks associated with its handling. By taking appropriate precautions, individuals can minimize the likelihood of experiencing adverse health effects.

- Q: Can fiberglass fabric be used for reinforcement in automotive parts?

- Indeed, automotive parts can be reinforced with fiberglass fabric. Renowned for its exceptional strength-to-weight ratio, fiberglass fabric proves to be an optimal material for reinforcing diverse components within automobiles. Its utilization is prevalent in the production of body panels, hoods, fenders, and other integral structural parts of vehicles. By endowing remarkable rigidity and stiffness, fiberglass fabric significantly enhances the overall strength and longevity of automotive parts. Furthermore, its resistance to corrosion, coupled with its ability to endure high temperatures, renders fiberglass fabric highly suitable for deployment within the automotive industry.

- Q: What is the typical warp and weft count of fiberglass fabrics?

- The specific application and desired strength and durability can cause variations in the warp and weft count of fiberglass fabrics. Generally, fiberglass fabrics tend to have a higher warp count compared to the weft count. This is because the warp yarns, running vertically, are thicker and stronger to ensure stability and resistance against stretching and tearing. Conversely, the weft yarns, running horizontally, are thinner and more flexible to allow the fabric to conform to different shapes and contours. The warp count for fiberglass fabrics typically ranges from 16 to 40 yarns per inch, while the weft count is slightly lower, ranging from 12 to 30 yarns per inch. These counts can also be measured in metric units, like yarns per centimeter. However, it's important to note that these counts may vary depending on the specific manufacturer, fabric weight, and intended use of the fiberglass fabric.

- Q: Is fiberglass fabric suitable for use in protective gloves?

- Yes, fiberglass fabric is suitable for use in protective gloves. It offers excellent heat resistance, durability, and protection against cuts and abrasions. Additionally, it provides insulation and is lightweight, making it a popular choice for gloves used in industries such as welding, foundries, and glass manufacturing.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fabric for Fiberglass - E-Glass Surfboards Fiberglass Fabric for Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords