Fiberglass Fabrics - e-glass fiberglass cloth

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Cloth Description:

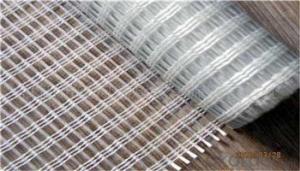

1.The fabric of fiberglass cloth is woven by fiber glass yarn, which is treated with silane coupling agent, the kind of weave is plain.

2.It is base material of high strength,low extensibility,coating with resin

easily and surface flat and so on.

Main Features of the Fiberglass Cloth:

It has good characteristics of high tensile strength, stable tension, and no defect appearance. The fiberglass fabric can be widely applied in different industrial application such as: PTFE, silicon, PVA, PVC, PU and acrylic coating, thermal, insulation and others application.

Fiberglass Cloth Images:

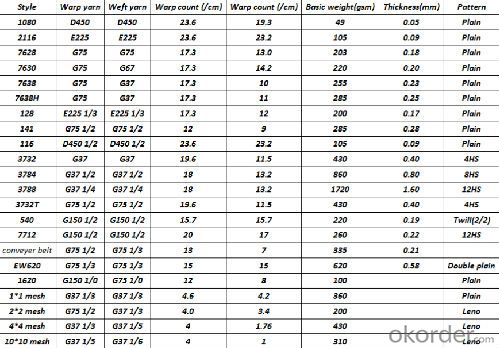

Fiberglass Cloth Specification:

FAQ of Fiberglass Cloth:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: What are the different fiberglass fabric weaves for thermal insulation?

- There are several different fiberglass fabric weaves that are commonly used for thermal insulation purposes. These weaves are designed to provide excellent heat resistance and insulation properties. One of the most common weaves used for thermal insulation is the plain weave. This weave consists of a simple over-under pattern, where each weft thread passes alternately over and under each warp thread. The plain weave is known for its balanced strength and stability, making it suitable for a wide range of applications. Another popular weave for thermal insulation is the satin weave. This weave is characterized by a series of floating warp or weft threads that pass over several consecutive threads before being interlaced again. The satin weave creates a smooth and lustrous fabric with a high degree of flexibility and drapeability. It is ideal for applications where a lightweight and flexible insulation solution is required. The twill weave is another option for fiberglass fabric used in thermal insulation. This weave is characterized by a diagonal pattern created by the interlacing of the warp and weft threads. Twill weaves are known for their strength and durability, making them suitable for applications that require a more robust insulation solution. Additionally, the leno weave is often used for thermal insulation. This weave involves the twisting of adjacent warp threads around each other to create small, open spaces in the fabric. These spaces allow for improved air circulation and moisture management, making leno weave fabrics ideal for applications where breathability is important. Overall, the choice of fiberglass fabric weave for thermal insulation will depend on the specific requirements of the application, such as desired insulation properties, flexibility, strength, and breathability.

- Q: Are fiberglass fabrics resistant to UV degradation?

- Yes, fiberglass fabrics are generally resistant to UV degradation. The composition of fiberglass, which includes glass fibers, makes it inherently resistant to the harmful effects of UV radiation. This property allows fiberglass fabrics to maintain their strength and durability when exposed to sunlight over extended periods of time.

- Q: Is fiberglass fabric suitable for making sports equipment bags?

- Yes, fiberglass fabric is suitable for making sports equipment bags. It is known for its durability, strength, and resistance to tearing, making it an ideal choice for bags that need to withstand heavy usage and potential impact. Additionally, fiberglass fabric is lightweight, which is advantageous for sports equipment bags that need to be carried around easily.

- Q: How does fiberglass fabric compare to other fabric materials in terms of cost?

- Fiberglass fabric can vary in cost depending on various factors such as quality, thickness, and specific application. Generally, fiberglass fabric tends to be more expensive than traditional fabrics such as cotton or polyester. However, when compared to specialized industrial fabrics like Kevlar or carbon fiber, fiberglass fabric often offers a more cost-effective solution. Fiberglass fabric's affordability is mainly due to its wide availability and relatively low production costs. Additionally, fiberglass fabric's durability and longevity can contribute to cost savings in the long run, as it may require less frequent replacement or repair compared to other fabric materials. Overall, while fiberglass fabric may not be the cheapest fabric material available, it is often considered a cost-effective choice for various applications.

- Q: Can fiberglass fabric be used for making automotive parts?

- Automotive parts can indeed be made using fiberglass fabric. Renowned for its robustness, longevity, and ability to withstand high temperatures and chemicals, fiberglass fabric proves to be an excellent choice for automotive purposes. It facilitates the creation of diverse automotive components like hoods, fenders, spoilers, and interior elements such as door panels. The flexibility of fiberglass fabric enables the production of bespoke automotive parts with intricate designs. Furthermore, its lightweight nature aids in enhancing fuel efficiency and overall vehicle performance.

- Q: Waterproof method of glass fiber cloth for toilet

- The pipe is worn through the root of the floor to strengthen the water.

- Q: Can fiberglass fabric be used for insulation boards?

- Yes, fiberglass fabric can be used for insulation boards. It is lightweight, flexible, and has excellent thermal insulating properties, making it a suitable choice for insulation applications.

- Q: Is fiberglass fabric suitable for making tents and awnings?

- Yes, fiberglass fabric is suitable for making tents and awnings. Fiberglass fabric is known for its durability, strength, and resistance to various weather conditions, making it an excellent choice for outdoor applications like tents and awnings. It is lightweight, yet provides excellent protection from the elements such as rain and wind. Additionally, fiberglass fabric has good UV resistance, which helps to prevent fading and damage from prolonged exposure to the sun. Its inherent fire-resistance properties also make it a safe choice for outdoor structures. Overall, fiberglass fabric is a suitable material for making tents and awnings as it offers a combination of strength, durability, and weather resistance necessary for these applications.

- Q: What are the different laminating options available for fiberglass fabric?

- There are several laminating options available for fiberglass fabric, including epoxy, polyester, vinyl ester, and phenolic. Each option offers specific properties and benefits, such as improved strength, chemical resistance, and fire retardancy. The choice of laminating option depends on the intended application and desired performance characteristics.

- Q: What about the leaking water made of fiberglass cloth?

- The principle and main street "in the way of roof leaks" principle is similar.

Send your message to us

Fiberglass Fabrics - e-glass fiberglass cloth

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords