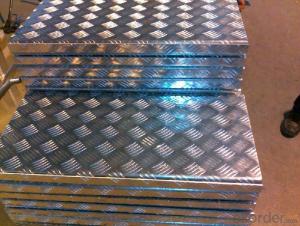

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Usage/Application of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

4. Production Flow of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Melting-Rolling- Cutting- Annealing--Packing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines. Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC.

- Q:Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Yes, aluminum sheets are highly suitable for manufacturing aircraft interiors. Aluminum is a lightweight, yet strong and durable material, making it ideal for aerospace applications. Its high strength-to-weight ratio allows for the construction of lightweight and fuel-efficient aircraft. Aluminum sheets are also highly corrosion-resistant, which is crucial in the aerospace industry where aircraft interiors are exposed to various environmental factors such as humidity and temperature changes. This corrosion resistance ensures the longevity and reliability of the aircraft interior components, reducing maintenance and replacement costs. Furthermore, aluminum sheets can be easily fabricated and formed into various shapes, allowing for the production of complex and customized aircraft interior components. They can be easily cut, bent, and welded, offering design flexibility and enabling manufacturers to create sleek and aesthetically pleasing interior designs. In addition to these technical advantages, aluminum is also a sustainable material. It is 100% recyclable, making it an environmentally friendly choice for aircraft interiors. The recycling process requires significantly less energy compared to primary aluminum production, reducing the carbon footprint associated with manufacturing. Overall, the combination of its lightweight properties, corrosion resistance, ease of fabrication, and sustainability make aluminum sheets highly suitable for manufacturing aircraft interiors.

- Q:How are the aluminum plates cut?

- Laser cutting can be combined with the above advantages, but the price is relatively high. A thicker aluminum sheet (above 6mm) is usually used in electric saws.

- Q:Aluminum siding is essentially maintenence-free, extremelydurable, and is a great insulator, even better than brick. Brickleaks air through the mortar between the bricks, especially in olderhouses that need tuckpointing. My question is, do you feel sidingstill has a declasse connotation, or is it getting more acceptableas the years go on?

- No worse than vinyl. The advantage vinyl has over aluminum is its resistance to denting. Siding is a good finish, but if you've already got a brick exterior, you're wasting the hard hours the masons put in to make it. If the brick has deteriorated or is horribly scarred, like having survived a hurricane or tornado, then sure, siding will spiff it up cosmetically as well as adding insulation value. That said, I'd rather take a house with aluminum siding over wood any day...and vinyl over that. If you get the siding in the color you want, as it's the entire thickness of the vinyl, powerwashing the outside won't take the color off as it could with painted wood or (though less likely) the finish on the aluminum...unless you *like* painting :)

- Q:What is aluminum curtain wall.

- In the closing means: aluminum curtain wall aluminum panel curtain wall mounted to the side plate finally called closing!On the aluminum ceiling installation knowledge and aluminum product knowledge welcome Baidu Guangzhou "China Hainan" brand aluminum ceiling understanding

- Q:What type of aluminium sheet is a food grade?

- Pure aluminum, alloy aluminum can be. However, the majority of pure aluminum. Used by customers. You can inquire about our company: dexincheng Pioneer Metals corporation. Baidu will find the phone soon.

- Q:Are aluminum sheets suitable for aircraft manufacturing?

- Indeed, aircraft manufacturing finds aluminum sheets to be highly suitable. The aerospace industry extensively utilizes aluminum owing to its exceptional blend of qualities, encompassing its lightweight nature, robust strength, ability to withstand corrosion, and outstanding malleability. Such attributes render aluminum an optimal substance for constructing diverse aircraft elements, including fuselages, wings, and structural components. Furthermore, aluminum alloys can be effortlessly fused, facilitating efficient manufacturing procedures. In totality, aluminum sheets assume a pivotal function in aircraft manufacturing, substantially enhancing the aircraft's overall performance, durability, and safety.

- Q:(2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

- Q:Are aluminum sheets suitable for packaging applications?

- Yes, aluminum sheets are highly suitable for packaging applications due to their lightweight, corrosion-resistant, and excellent barrier properties. They can effectively protect products from moisture, light, and oxygen, ensuring longer shelf life and freshness. Additionally, aluminum sheets are easily formable, making them suitable for various packaging formats like cans, foils, and pouches.

- Q:What are the different types of surface treatments available for painted aluminum sheets?

- Painted aluminum sheets can undergo a variety of surface treatments to enhance their appearance, durability, and protection against corrosion and damage. Anodizing is a commonly used surface treatment where aluminum sheets are immersed in an electrolytic solution and an electric current is passed through them. This process forms a protective oxide layer on the surface, improving corrosion resistance and providing a base for painting or other decorative finishes. Another popular treatment is powder coating, which involves applying a dry powder to the aluminum's surface and then heating it to create a tough, protective layer. This coating is known for its durability, resistance to fading and chipping, and ability to offer a wide range of colors and finishes. Apart from anodizing and powder coating, there are other surface treatments available for painted aluminum sheets. Chemical conversion coating entails applying a chemical solution to create a protective layer, while laminate coatings involve adding a thin film or laminate for additional protection and decoration. In conclusion, the various surface treatments for painted aluminum sheets provide several advantages, such as improved appearance, durability, and corrosion resistance. The choice of treatment depends on the specific requirements and desired outcomes for the aluminum sheets.

- Q:What is the weight of aluminum sheets?

- The weight of aluminum sheets can vary depending on the thickness and dimensions of the sheet. As a general guideline, the weight of aluminum sheets can range from about 2.7 grams per square centimeter (g/cm^2) for thin sheets to around 6.9 g/cm^2 for thicker sheets. However, it is important to note that these values are approximate and can vary slightly depending on the specific alloy and manufacturing process used. Therefore, it is recommended to consult the manufacturer or supplier for precise weight specifications for a particular aluminum sheet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords