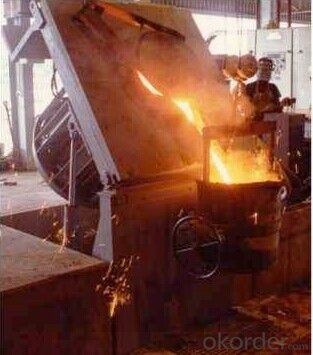

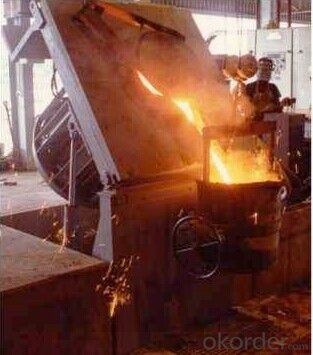

Induction Melting Furnace for Iron, Aluminum, Brass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

Overview and Uses

"IF furnace" - also known as the "medium frequency coreless induction furnace"; apply to iron and steel, copper, Ceruse,aluminum, zinc, nickel, gold and silver and other metal melting, heating, insulation, and forging, sintering, hot rolling, bending forming pre-heat treatment. Is mainly used in melting foundry industry.

1,Using a zero-voltage scanning soft-start mode, in any case may at any time to start or stop, will not have impact on power supply.

2 ,Rapid melting, the production cost is low; pollution is small, comply with environmental requirements;

3,A direct effect from the cold furnace melting. Dissolved material will be fully dumped clean. Molten material easy to replace.

4,Power adjustment flexibility. Be able to continuously smooth adjustment. Temperature uniformity can be easily controlled. Oxidation burning less. Metal components evenly.

5 ,Furnace shell using cast aluminum or steel structure, small footprint; furnace flip dump convenience, according to the need to use electric, manual, hydraulic tilting furnace and other means.

6,Designed to automatically adjust angle of inverter circuit that can automatically adjust the load impedance match, without adjustment of capacitance compensation and always run the equipment in good working condition; power supply system diagnostic error function, easy maintenance.

"IF furnace" - also known as the "medium frequency coreless induction furnace"; apply to iron and steel, copper, Ceruse,aluminum, zinc, nickel, gold and silver and other metal melting, heating, insulation, and forging, sintering, hot rolling, bending forming pre-heat treatment. Is mainly used in melting foundry industry.

1,Using a zero-voltage scanning soft-start mode, in any case may at any time to start or stop, will not have impact on power supply.

2 ,Rapid melting, the production cost is low; pollution is small, comply with environmental requirements;

3,A direct effect from the cold furnace melting. Dissolved material will be fully dumped clean. Molten material easy to replace.

4,Power adjustment flexibility. Be able to continuously smooth adjustment. Temperature uniformity can be easily controlled. Oxidation burning less. Metal components evenly.

5 ,Furnace shell using cast aluminum or steel structure, small footprint; furnace flip dump convenience, according to the need to use electric, manual, hydraulic tilting furnace and other means.

6,Designed to automatically adjust angle of inverter circuit that can automatically adjust the load impedance match, without adjustment of capacitance compensation and always run the equipment in good working condition; power supply system diagnostic error function, easy maintenance.

| GY-SCR100KW melting 100KG IRON | ||||||

| MF Melting furnace | Range of molten iron capacity | Ton | 0.1~0.15 | |||

| Max working temperature | C | 1650 | ||||

| Melting rate | ton/h | 0.1~0.15 | ||||

| Cooling water | R ate of flow | ton/h | 15 | |||

| Pressure | Mpa | 0.2 | ||||

| water inflow temperature | C | > 40 | ||||

| Temperature rise | C | > 20 | ||||

| Induction heater voltage | V | 750 | ||||

| Induction inner diameter | mm | 360 | ||||

| Induction heater total height | mm | 500 | ||||

| Turndown method | mechanical drive | |||||

| MF Induction heating machine | Range of power | kw | 100 | |||

| Incoming line voltage | V | 380 | ||||

| Max incoming line current | A | 160 | ||||

| rectifier pulse number | pulse | 6 | ||||

| cooling water | rate of flow | ton/h | 50 | |||

| pressure | Mpa | 0.1 | ||||

| water inflow temperature | C | > 35 | ||||

| Temperature rise | C | >15 | ||||

| MF voltage | V | 750 | ||||

| MF frequency | HZ | 1000 | ||||

- Q: Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q: What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q: Should the industrial furnace shell cool down?

- If the furnace shell temperature is too high, it shows that the lining is not good or damaged, so it should be repaired in time. If you do not repair, take the cooling way, undesirable. Because this will cause a lot of heat loss, resulting in waste of energy, increase production costs, and affect the service life of the furnace.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Basically, no industrial furnace manufacturer can do all types of stoves.Often associated with the industry is very large,so your ranking is basically meaningless.

- Q: What is industrial furnace masonry?

- Plane construction must level, slope construction must find slope,refractory bricks must be selected and processed according to masonry requirements.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Of course, the difference is like the difference between a hog cap and a 100 story building. See the industrial furnace manual.

- Q: What is the difference in structure between industrial furnace and boiler?

- Industrial furnace: main heating, steel and other metal materials, or ore and other materials. An industrial furnace of higher temperature, such as forging or heat treatment. Therefore, the energy consumption is large, and the insulation layer is designed to be thicker, and the structure is designed for the final purpose of the production purpose, the product process and the production efficiency.

- Q: What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

Send your message to us

Induction Melting Furnace for Iron, Aluminum, Brass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords