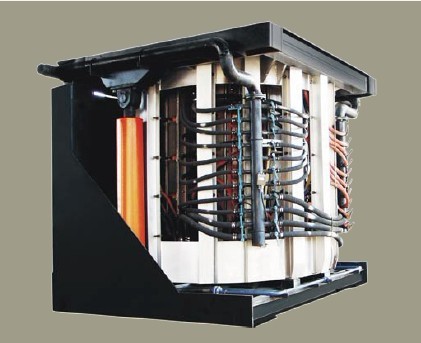

industrial smelting furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Our industrial smelting furnace and medium Frequency Induction Furnace with technology of dual Track furnaceDual Track furnace

Our industrial smelting furnace for melting steel to produce billets and rebar etc.Detail spec.:

1ton Dual track KGPS induction furnaceMedium Frequency Induction Furnace Dual Track furnace

Technical parameter

Item | Unit | Data |

Furnace parameter |

| 1t |

Rated capacity | t | 1 |

Maximum capacity | t | 1.2 |

Induction coil inside diameterΦ | mm | 700 |

Induction coil height | mm | 820 |

Maximum working temperature | °C | 1750 |

Electrical parameter |

|

|

Transformer capacity | KVA | 1000 |

Transformer primary voltage | KV | 10 |

Transformer secondary voltage | V | 660 |

Rated power of MF power supply | KW | 800 |

Maximum output voltage of MF power supply | V | 1450 |

Coil voltage | V | 2900 |

Rated working frequency | Hz | 1000 |

Power supply convert frequency | % | 96 |

Startup successful frequency | % | 100 |

Composite parameter |

|

|

Melting rate(rise to 1450°C) | t/h | 1.4 |

Melting power consumption (rise to 1450°C) | KW.h/t | 580 |

Working noise | db | ≤75 |

Hydraulic system |

|

|

Hydraulic station capacity | L | 200 |

Working pressure | MPa | 11 |

Hydraulic medium |

| Hydraulic oil |

Cooling water system |

|

|

flow | M3/h | 34 |

Water supply pressure | MPa | 0.2~0.3 |

Inlet water temperature | °C | 5~35 |

Outlet water temperature | °C | 35~55 |

The way of rectifier transformer what is our company recommended as follow:

The specification of rectifier transformer (double 6-pulse)

Furnace capacity | Power of MF power supply(KW) | Transformer Capacity(KVA) | Voltage combination | Coupling group mark | Impedance voltage (%) | |

Primary side (KV) | Secondary side (V) | |||||

1t | 800 | 1000 | 10 | 660 | Δ/Y0-12 | 6~8 |

0

1 Remark:It should be has no-load voltage adjustment switch in high voltage side of transformer, the voltage is adjusted at -0.5%, 0, +0.5% 3 level.

The rectifier tube and inverter tube are chosen as follow specification:

Furnace model | KK tube | KP tube |

1t | KK—1200A/1800V | KP—1000A/2200V |

- Q: What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q: What are the combustion equipments used in industrial boilers?

- Main auxiliary equipment for general boilers:1. domestic appliances 2. civilian gas boiler 3. industrial gas furnace.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: Why does the burner of industrial furnace burn occasionally?

- The general process for burner ignition, blowing furnace, electric spark ignition, solenoid valve, open the gas in case of delayed spark ignition, detection device detects the flame, the controller accepts signal so that the solenoid valve open, gas continuous normal combustion. However, if the ignition fails or the burner fires, the detector cannot detect the flame, which causes the solenoid valve to close and the burner flameout.

- Q: How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

- Q: How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q: Brief introduction to repair of industrial furnace

- The working condition of industrial furnace is very bad. It is affected by high temperature, slag erosion and burden wear. Therefore, its working condition changes quickly and its service life is short.

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

industrial smelting furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords