Small industrial induction furnace machinery 20KW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Small Induction Furnace

1.Based on latest IGBT

2.Especially suitable for laboratory use

3.Ensure safety

4.Energy saving

20kw small industrial induction furnace machinery

About induction heating

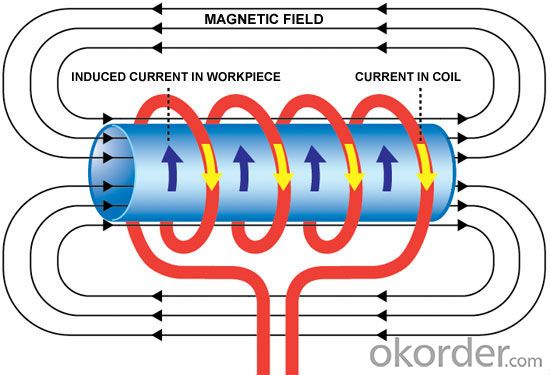

Induction heating is a form of non-contact heating for conductive materials. When alternating current flows in

induced coil, varying electromagnetic is set up around the coil, eddy current is generated in the workpiece

( the workpiece must be electrically conductive).

![]()

Rated Power output | 20KW |

3 phase input(V/Hz) | 380V/50Hz |

Operating voltage | 380V |

Input power | 22KW |

Oscillation frequency | 20-50KHZ |

Efficiency | 90% |

Duty cycle | 100% |

Current input | 30-40A |

Voltage range | 360-420V |

Cooling water flow | 24L/Min |

Water temperature protection point | 45°C |

Weight of power unit | 65-75kg |

Dimension of power unit(mm 3) | 500*400*650mm³ |

![]()

Main feature

induction heating work

IGBT power supply

safe and stability

environmetal and save energy

installation simple , operate easy

small size , move conveninetly

heating fast , heating uniformity

we can offer

induction heating equipments

induction coil ( the coil to be made depend on your heating work requirements and the size of your workpieces )

operation manual

![]()

smelting for iron , steel , cooper , aluminum

smelting for presious metals , such as gold , sliver ,

smelting for ferrous and non ferrous metals

smelting for alloys

smelting for metal rods

other smelting work for metal products

- Q:What's the role of anchor bricks in industrial furnaces?

- Anchorage brick is a new type of anchor brick relates to an industrial furnace, in particular to anchor brick of an industrial furnace roof, including column hanging end and the anchor structure, opened in the anchor on the surface of the spacing of the grooves in the anchor on at least one surface is arranged along the length direction ribs is provided with ribs, the ribs of the reinforcement and anchorage tension, tensile and flexural strength was obviously improved, the stress generated in the groove at the bar at the barrier can not continue to transfer, so the anchor brick of this kind of structure is not easy to break.

- Q:What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q:What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

- Q:Should the industrial furnace shell cool down?

- If the furnace shell temperature is too high, it shows that the lining is not good or damaged, so it should be repaired in time. If you do not repair, take the cooling way, undesirable. Because this will cause a lot of heat loss, resulting in waste of energy, increase production costs, and affect the service life of the furnace.

- Q:Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q:What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q:Why does the burner of industrial furnace burn occasionally?

- The basic structure of the complete ignition system is the ignition device and flameout protection device. The ignition burner includes an ignition electrode and an igniter (equipped with some external type transformer, voltage transformer) through the above 10kV, the ignition electrode spark ignition of high voltage discharge to ignite gas column.

- Q:What is industrial furnace masonry?

- Pre construction and recording shall be carried out on complex and important parts of industrial furnaces,masonry of all kinds of masonry shall be made with staggered joint masonry.

- Q:How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q:What is the difference in structure between industrial furnace and boiler?

- Industrial furnace: main heating, steel and other metal materials, or ore and other materials. An industrial furnace of higher temperature, such as forging or heat treatment. Therefore, the energy consumption is large, and the insulation layer is designed to be thicker, and the structure is designed for the final purpose of the production purpose, the product process and the production efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Small industrial induction furnace machinery 20KW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products