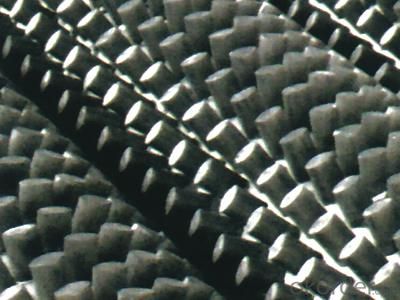

Studded Tube / Finned Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GROUP mainly produces the following products:

l Refinery/chemical furnaces, incinerators, coal (liquid) chemical reformers

l Waste heat boilers, thermal medium boilers

l Class A1 /A2 pressure vessels

l Reactors, Heat Exchangers & Towers

l Oil tanks/accessories/mixers, alloy steel precision castings

l Four classes of piping supports and hangers used in fired-electric/thermo-electric/nuclear electric power industries and dampers

l Flue gas/air/coal powder duct and its attachments

l Boiler ancillaries, water treatment devices and so on

GROUP obtains the following certificates:

l Class A Certificate of Engineering Design

l Design License of Pressure Vessel (Class A3)

l Manufacture License of Pressure Vessel (Class A3)

l Design & Manufacture License of Pressure Piping (Class A)

l Manufacture License of Waste heat boilers (Class A), thermal medium boilers

l ISO 9001:2000 Quality Management System

l ASME U and ASME S

l Enterprise Credit: AAA

As the Leading Enterprise of Fired Heaters, Corporation can design and fabricate common Fired Heaters as well as uncommon ones independently such as Reactor Charge Heater for Straight-run Gasoline Hydrogenation Unit (7*104 t/a), 6t/d Testing Unit for Direct Liquefaction, Coal Liquefaction Reactor Heater for Stable Unit of Coal Liquefaction and Hydrogenation, Two-stage Fired Heater for Pyrolysis Gasoline hydrogenation Unit of Ethylene Technical Reform (7.2*105 t/a), Reboiler for Depentanizer of Aromatic Hydrocarbon Unit (2.5*105 t/a), Reboiler for Reboiling Deheptane Tower, Four-in-one Reforming Heater for Reforming Project (2*105 t, 6*105 t, 8*105 t), Acetylene Cracking Heater for PTMEG Unit, etc.

- Q: Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q: Should the industrial furnace shell cool down?

- The function of furnace shell is beautiful, protective lining, fixed function accessories and so on.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q: What are the combustion equipments used in industrial boilers?

- The main auxiliary equipments of the general boiler are: upper coal machine, ash blower, blower, draught fan, economizer, feed pump and water treatment unit. Oil boilers are: oil pumps, burners, tanks and so on.

- Q: What's the role of anchor bricks in industrial furnaces?

- These layers need to be joined and anchored. Anchor brick is this role. The heat insulation layer at the horizontal section of the flue is mostly a narrow cavity.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: What are the advantages of a vacuum furnace?

- High degree of integration of mechanical and electrical. On the basis of the improvement of temperature measurement and control accuracy, the workpiece movement, air pressure regulation, power adjustment can be programmed in advance, and quenching and tempering are carried out according to the steps.

- Q: How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

Studded Tube / Finned Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords