Low energy consumption Induction furnace for melting iron ore

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard seaworthy treatment |

| Delivery Detail: | 9 months |

Specifications

All confined protective atmosphere

Onload stepless magnetic voltage regulating

Electrode load cell

coaxial conducting

Key Feature:

l State-of-the-art Technology & Facilities

l More than 30 years experience in design & production of bulk material handling system

l More 30% stall are engineers and technical background;

l Patented technology,professional design,accuracy control,safe and reliable operation

l Max. 150t ESR furnace;

Design Management:

![]()

3D • DESIGNFE ANALYSIS • 3-LEVEL REVIEW POLICY • COMPONENT PROCESS ROADMAP & REQUIREMENT

• COMPONENT SINGLE PIECE DRAWING

Process Management:

![]()

Welding & Machining MPP • Welding Process Flow Chart • Welding Procedure • Heat Treatment Procedure

Assembly Procedure • Painting Procedure • Lifting Procedure

Workshop Facilities (Phase 1):

![]()

Welding workshop | Material preparation workshop | Machining workshop | Assembly workshop | |

Dimension | 205m×36m×2 | 156m×26m | 217m×36m×2 | 217m×36m |

Overhead crane | 2×150T/16m | 75T/16m | 2×150T/16m | 2×150T/16m |

Main gate | 16m×12m | 12m×10m | 16m×12m | 16m×12m |

| ||||

After-sales Service:

![]()

Supervision for Installation, Commissioning & Training for Operation & Maintenance

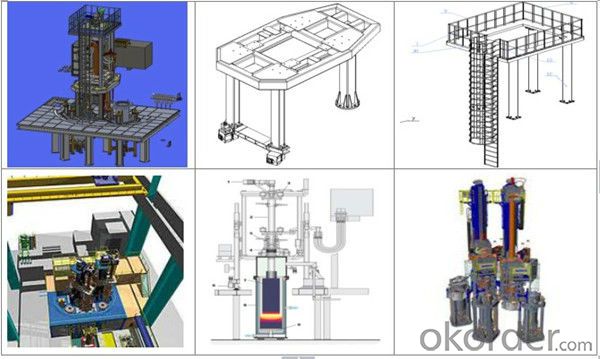

Pictures:

![]()

- Q: Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q: What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q: Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q: Why does the burner of industrial furnace burn occasionally?

- The general process for burner ignition, blowing furnace, electric spark ignition, solenoid valve, open the gas in case of delayed spark ignition, detection device detects the flame, the controller accepts signal so that the solenoid valve open, gas continuous normal combustion. However, if the ignition fails or the burner fires, the detector cannot detect the flame, which causes the solenoid valve to close and the burner flameout.

- Q: How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q: Brief introduction to repair of industrial furnace

- Compared with other equipment, industrial furnace repair has many characteristics: more repair times, more maintenance costs, more non-standard equipment and unsafe factors.

- Q: What is the difference in structure between industrial furnace and boiler?

- Industrial furnace: main heating, steel and other metal materials, or ore and other materials. An industrial furnace of higher temperature, such as forging or heat treatment. Therefore, the energy consumption is large, and the insulation layer is designed to be thicker, and the structure is designed for the final purpose of the production purpose, the product process and the production efficiency.

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

Low energy consumption Induction furnace for melting iron ore

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords