0.5ton Coreless Medium Frequency Induction Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

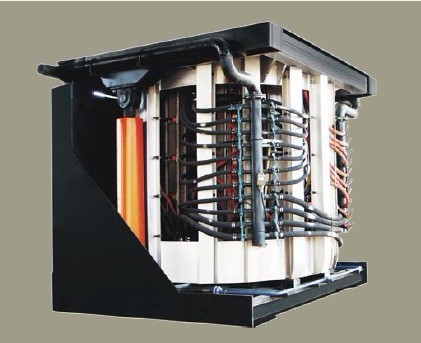

GWG-J series Coreless Medium Frequency Induction Melting Furnace

GWG-J series Coreless Medium Frequency Induction Melting FurnaceThis GWG-J series Coreless Medium Frequency Induction Melting Furnace is for melting cast steel, cast iron, stainless steel, copper, aluminum and other metals or its alloy. It can also be used together with self-heated furnaces and electric arc furnace for heating or keeping warm/holding the molten iron and molten steel.

It is particularly suitable for medium-size or big enterprises.

Structure Features1. Solid steel structure and durable;

2. Good magnetic isolation, safe and reliable;

3. Solid frequency conversion power supply, easy operation; Adjustable power rate, easy operation and maintenance;

4. Easy to start up with load or free of load.

Electrical Feature:

1. Digital CMOS chip (U. S. ASIC-2-12), with the highest degree of integration at home, is used in control circuit, the overall machine controlled through one single panel;

2. Frequency-sweep zero voltage start, high success rate, no shock;

3. Automatic resistance adjustment, permanent power output, 10-20% energy saved in comparison with domestic traditional machine of the type;

4. Auto phase sequence adaptation, free of synchronization;

5. Good performance in reload staring, auto recovery;

6. Highly integrated in controlling circuit, free of use of high-rate starter and relay loop, fairly low failure rate;

7. Wholly digital design, strong in anti-interference, no temperature shift when in continuous working;

8. Multi-protection functions (for over current, over voltage, insufficient water pressure, power failure, or phase absence), and mishandling will not cause damage to machine.

Model explanation ( GWG-0.5-250/1J for example}

GWG--------Steel Shell Coreless Medium Frequency Induction Melting Furnace

-0.5-------Rated Capacity 1 Ton (1000kg)

-250-------Rated Power 250Kw

/1--------1000Hz (1KHz)

-J---------Hydraulic tilting

| Model | Input Power | Input Volt. | Incoming Curr. | Rated Power | DC Curr. | DC Volt. | Melting Rate | Working Freq. | Working Volt. | Rated Capacity | Power Consumption |

| Kw | V/pulse | A | Kw | A | V | T/H | Hz | V | T | KWH/T | |

| GWG-0.5-250/1J | 280 | 380/6 | 400 | 250 | 500 | 500 | 0.4 | 1000 | 1500 | 0.5 | 770 |

| GWG-0.75-400/1J | 400 | 380/6 | 650 | 400 | 800 | 500 | 0.6 | 1000 | 1500 | 0.75 | 770 |

| GWG-1-750/1J | 800 | 380/6 | 1200 | 750 | 1500 | 500 | 0.9 | 1000 | 1500 | 1 | 720 |

| 690/6 | 700 | 850 | 880 | 500 | 2600 | 660 | |||||

| GWG-1.5-1000/0.5J | 1100 | 690/6 | 912 | 1000 | 1140 | 880 | 1.2 | 500 | 2600 | 1.5 | 700 |

| GWG-2-1500/0.5J | 1650 | 690/6 | 1360 | 1500 | 1700 | 880 | 1.7 | 500 | 2600 | 2 | 675 |

| GWG-3-2500/0.5J | 2750 | 690/6 | 2275 | 2500 | 2840 | 880 | 2.56 | 500 | 2600 | 3 | 610 |

| 950/6 | 1700 | 2080 | 1250 | 3200 | 560 | ||||||

| GWG-4-3000/0.5J | 3300 | 690/6 | 2730 | 3000 | 3410 | 880 | 3.2 | 500 | 2600 | 4 | 590 |

| 950/6 | 2040 | 2500 | 1250 | 3200 | 560 | ||||||

| GWG-5-4000/0.5J | 4400 | 950/6 | 2300 | 4000 | 3330 | 1250 | 5 | 500 | 3400 | 5 | 500/550 |

| GWG-6-4000/0.5J | 4400 | 950/12 | 2300 | 4000 | 3330 | 1250 | 5 | 500 | 3400 | 6 | 500/550 |

| GWG-8-5000/0.5J | 5000 | 950/12 | 3400 | 5000 | 4200 | 1250 | 7~8 | 500 | 3400 | 8 | 500/550 |

| GWG-10-6000/0.5J | 6300 | 950/12 | 3750 | 6000 | 4600 | 1250 | 9~10 | 500 | 3400 | 10 | 500/550 |

| GWG-12-8000/0.5J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 10~11 | 500 | 3400 | 12 | 500-550 |

| GWG-12-8000/0.25J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 10~11 | 250 | 3400 | 12 | 500-550 |

| GWG-15-8000/0.25J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 9~10 | 250 | 3400 | 15 | 550-590 |

| GWG-15-10000/0.25J | 10000 | 950/24 | 6500 | 10000 | 8000 | 1250 | 13~14 | 250 | 3400 | 15 | 500-550 |

| GWG-18-12000/0.25J | 12000 | 950/24 | 8160 | 12000 | 10000 | 1200 | 13~14 | 250 | 3400 | 18 | 500-550 |

| GWG-20-12000/0.25J | 12000 | 950/24 | 8160 | 12000 | 10000 | 1200 | 13~14 | 250 | 3400 | 20 | 500-550 |

| GWG-25-14000/0.25J | 14000 | 950/24 | 9460 | 14000 | 11600 | 1200 | 13~15 | 150~200 | 3400 | 25 | 500-550 |

| GWG-30-16000/0.2J | 16000 | 950/24 | 10850 | 16000 | 13300 | 1200 | 15~16 | 150~200 | 3400 | 30 | 500-550 |

| GWG-40-18000/0.2J | 18000 | 950/24 | 12240 | 18000 | 15000 | 1200 | 20~22 | 150~200 | 3400 | 40 | 500-550 |

- Q: Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q: Should the industrial furnace shell cool down?

- The function of furnace shell is beautiful, protective lining, fixed function accessories and so on.

- Q: What is industrial furnace masonry?

- Pre construction and recording shall be carried out on complex and important parts of industrial furnaces,masonry of all kinds of masonry shall be made with staggered joint masonry.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q: What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Furnace industry is not generally Mason walls, needs to have a professional operation and rich construction experience, high level of industrial furnace is difficult to get.

- Q: Brief introduction to repair of industrial furnace

- The industrial furnace is the main production equipment in the machinery industry. The repair of industrial furnace directly affects the quality, high yield, long life, low consumption and safe production of the furnace.

- Q: What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

- Q: What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

Send your message to us

0.5ton Coreless Medium Frequency Induction Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches