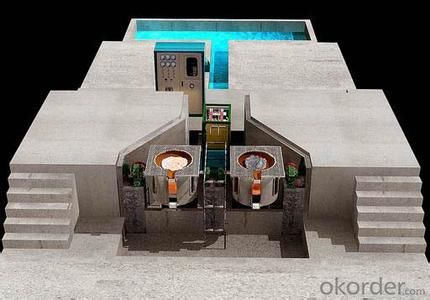

Vacuum IF (medium Frequency) Induction Furnace

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | induction melting furnace is packaged in Standard export wooden cases and containers |

| Delivery Detail: | 10-1500days |

Specifications

induction melting furnace

1.Factory inspection

2.Energy-saving

3.Free technical training and after-sale service

Vacuum metal metallurgy Induction Furnace/Melting Furnace

Specializing in this field for many years

High quality products and favorable prices

Quick delivery and satisfying service

Hot-selling all over the world

1.Introdution

The vacuum induction melting furnace is mainly applied to scientific research and industrial manufacture. In vacuum environment, this vacuum metal melting equipment utilizes medium-frequency induction heater to melt metals. Featuring small floor space, our industrial electric furnace delivers lucrative scientific research and industrial manufacture.

Our vacuum induction melting furnace is a batch-type furnace. This metal metallurgy equipment is greatly recommended for melting and casting of alloy steel, nickel-based alloy and rare earth element in vacuum or protective gas environment. It also finds applications in refining metals.

2.Technical parameters

| Model | Power | Frequency | Max. working temperature | Dried furnace capacity | Max. vacuum degree | Pressure rising rate | Medium-frequency power |

| EF-3 | 30kW | 4000HZ | 1650℃ | 3kg | 6.67× 10-3Pa | 6Pa/h | IGBT |

| EF-10 | 60kW | 1500HZ | 1650℃ | 10kg | 6.67× 10-3Pa | 6Pa/h | IGBT |

| EF-25 | 100kW | 2000HZ | 1650℃ | 25kg | 6.67× 10-3Pa | 6Pa/h | IGBT |

| EF-50 | 100kW | 1500HZ | 1650℃ | 50kg | 6.67× 10-3Pa | 6Pa/h | KGPS |

| EF-150 | 200kW | 1500HZ | 1650℃ | 150kg | 6.67× 10-3Pa | 6Pa/h | KGPS |

| EF-200 | 250kW | 2500HZ | 1600℃ | 200kg | 6.7×10-2Pa | 6Pa/h | KGPS |

- Q: Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q: Should the industrial furnace shell cool down?

- If the furnace shell temperature is too high, it shows that the lining is not good or damaged, so it should be repaired in time. If you do not repair, take the cooling way, undesirable. Because this will cause a lot of heat loss, resulting in waste of energy, increase production costs, and affect the service life of the furnace.

- Q: What are the combustion equipments used in industrial boilers?

- The main auxiliary equipments of the general boiler are: upper coal machine, ash blower, blower, draught fan, economizer, feed pump and water treatment unit. Oil boilers are: oil pumps, burners, tanks and so on.

- Q: What is industrial furnace masonry?

- Pre construction and recording shall be carried out on complex and important parts of industrial furnaces,masonry of all kinds of masonry shall be made with staggered joint masonry.

- Q: What's the role of anchor bricks in industrial furnaces?

- These layers need to be joined and anchored. Anchor brick is this role. The heat insulation layer at the horizontal section of the flue is mostly a narrow cavity.

- Q: How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q: How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

- Q: Brief introduction to repair of industrial furnace

- The working condition of industrial furnace is very bad. It is affected by high temperature, slag erosion and burden wear. Therefore, its working condition changes quickly and its service life is short.

- Q: What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

- Q: What is an industrial furnace pit?

- Later, a chamber kiln with a semi closed or fully enclosed kiln made of refractory bricks can be used as fuel for coal, gas or oil, and electricity can be used as heat source. The workpiece will be heated in the kiln hearth.

Send your message to us

Vacuum IF (medium Frequency) Induction Furnace

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches