Medium Frequency Induction Furnace, Melting Furnace

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plywood Cases |

| Delivery Detail: | 25days to 120days |

Specifications

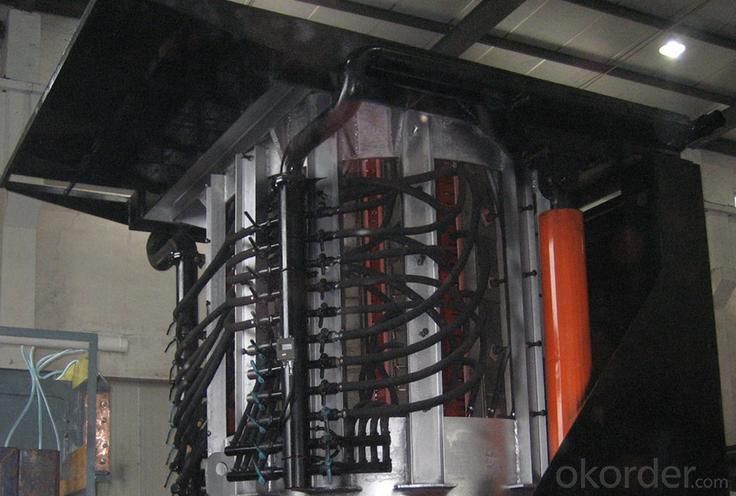

Medium Frequency Induction Furnace

Medium Frequency Melting Furnace

For melting steel, cast iron, stainless steel, copper

Coreless Medium Frequency Melting Furnace

· Application

2. Good magnetic isolation, safe and reliable;

3. Solid frequency conversion power supply, easy operation; Adjustable power rate, easy operation and maintenance;

4. Easy to start up with load or free of load.

1. Digital CMOS chip (U. S. ASIC-2-12), with the highest degree of integration at home, is used in control circuit, the overall machine controlled through one single panel;

2. Frequency-sweep zero voltage start, high success rate, no shock;

3. Automatic resistance adjustment, permanent power output, 10-20% energy saved in comparison with domestic traditional machine of the type;

4. Auto phase sequence adaptation, free of synchronization;

5. Good performance in reload staring, auto recovery;

6. Highly integrated in controlling circuit, free of use of high-rate starter and relay loop, fairly low failure rate;

7. Wholly digital design, strong in anti-interference, no temperature shift when in continuous working;

8. Multi-protection functions (for over current, over voltage, insufficient water pressure, power failure, or phase absence), and mishandling will not cause damage to machine.

· Model explanation ( GWG-1-750/1J for example}

GWG--------Steel Shell Medium Frequency Coreless Induction Furnace, Melting Furnace

-1-------Rated Capacity 1 Ton (1000kg)

-750-------Rated Power 750Kw

/1--------1000Hz (1KHz)

-J---------Hydraulic tilting

| Model | Input Power | Input Volt. | Incoming Curr. | Rated Power | DC Curr. | DC Volt. | Melting Rate | Working Freq. | Working Volt. | Rated Capacity | Power Consumption |

Kw | V/pulse | A | Kw | A | V | T/H | Hz | V | T | KWH/T | |

| GWG-0.5-250/1J | 280 | 380/6 | 400 | 250 | 500 | 500 | 0.4 | 1000 | 1500 | 0.5 | 770 |

| GWG-0.75-400/1J | 400 | 380/6 | 650 | 400 | 800 | 500 | 0.6 | 1000 | 1500 | 0.75 | 770 |

| GWG-1-750/1J | 800 | 380/6 | 1200 | 750 | 1500 | 500 | 0.9 | 1000 | 1500 | 1 | 720 |

| 690/6 | 700 | 850 | 880 | 500 | 2600 | 660 | |||||

| GWG-1.5-1000/0.5J | 1100 | 690/6 | 912 | 1000 | 1140 | 880 | 1.2 | 500 | 2600 | 1.5 | 700 |

| GWG-2-1500/0.5J | 1650 | 690/6 | 1360 | 1500 | 1700 | 880 | 1.7 | 500 | 2600 | 2 | 675 |

| GWG-3-2500/0.5J | 2750 | 690/6 | 2275 | 2500 | 2840 | 880 | 2.56 | 500 | 2600 | 3 | 610 |

| 950/6 | 1700 | 2080 | 1250 | 3200 | 560 | ||||||

| GWG-4-3000/0.5J | 3300 | 690/6 | 2730 | 3000 | 3410 | 880 | 3.2 | 500 | 2600 | 4 | 590 |

| 950/6 | 2040 | 2500 | 1250 | 3200 | 560 | ||||||

| GWG-5-4000/0.5J | 4400 | 950/6 | 2300 | 4000 | 3330 | 1250 | 5 | 500 | 3400 | 5 | 500/550 |

| GWG-6-4000/0.5J | 4400 | 950/12 | 2300 | 4000 | 3330 | 1250 | 5 | 500 | 3400 | 6 | 500/550 |

| GWG-8-5000/0.5J | 5000 | 950/12 | 3400 | 5000 | 4200 | 1250 | 7~8 | 500 | 3400 | 8 | 500/550 |

| GWG-10-6000/0.5J | 6300 | 950/12 | 3750 | 6000 | 4600 | 1250 | 9~10 | 500 | 3400 | 10 | 500/550 |

| GWG-12-8000/0.5J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 10~11 | 500 | 3400 | 12 | 500-550 |

| GWG-12-8000/0.25J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 10~11 | 250 | 3400 | 12 | 500-550 |

| GWG-15-8000/0.25J | 8000 | 950/12 | 4900 | 8000 | 6000 | 1250 | 9~10 | 250 | 3400 | 15 | 550-590 |

| GWG-15-10000/0.25J | 10000 | 950/24 | 6500 | 10000 | 8000 | 1250 | 13~14 | 250 | 3400 | 15 | 500-550 |

| GWG-18-12000/0.25J | 12000 | 950/24 | 8160 | 12000 | 10000 | 1200 | 13~14 | 250 | 3400 | 18 | 500-550 |

| GWG-20-12000/0.25J | 12000 | 950/24 | 8160 | 12000 | 10000 | 1200 | 13~14 | 250 | 3400 | 20 | 500-550 |

| GWG-25-14000/0.25J | 14000 | 950/24 | 9460 | 14000 | 11600 | 1200 | 13~15 | 150~200 | 3400 | 25 | 500-550 |

| GWG-30-16000/0.2J | 16000 | 950/24 | 10850 | 16000 | 13300 | 1200 | 15~16 | 150~200 | 3400 | 30 | 500-550 |

| GWG-40-18000/0.2J | 18000 | 950/24 | 12240 | 18000 | 15000 | 1200 | 20~22 | 150~200 | 3400 | 40 | 500-550 |

- Q: Selection of heat preservation material for industrial furnace

- Ceramic fiber blanket can be used.Ceramic fiber blanket color white, regular size, set fire, heat insulation, insulation in one. Free from any binding agent.

- Q: What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q: Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q: What is industrial furnace masonry?

- Plane construction must level, slope construction must find slope,refractory bricks must be selected and processed according to masonry requirements.

- Q: How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

- Q: What are the advantages of a vacuum furnace?

- High degree of integration of mechanical and electrical. On the basis of the improvement of temperature measurement and control accuracy, the workpiece movement, air pressure regulation, power adjustment can be programmed in advance, and quenching and tempering are carried out according to the steps.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Of course, the difference is like the difference between a hog cap and a 100 story building. See the industrial furnace manual.

- Q: Brief introduction to repair of industrial furnace

- The working condition of industrial furnace is very bad. It is affected by high temperature, slag erosion and burden wear. Therefore, its working condition changes quickly and its service life is short.

- Q: What is the difference in structure between industrial furnace and boiler?

- From the way: industrial furnace (electricity, natural gas, gas, induction heating is considered electricity), boilers (coal, all kinds of hot exhaust gas, a variety of gas, seemingly less electricity).

Send your message to us

Medium Frequency Induction Furnace, Melting Furnace

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords