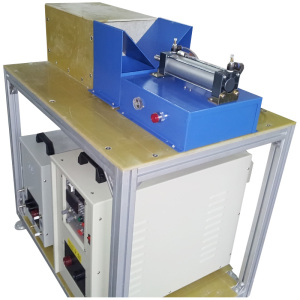

Induction Forging Furnace (ORD-15KW-300KW)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

MF Forging Furnace:

Advantage:

1 More than ten years experience, stable and goods performance

2 CE certificated

3 Copperated with ZHOUDAFU, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

4 Suitable for different bars to forging

5 Two transformer ratios, can match better different length induction coil

6 The Frequency can reach to 1kHz

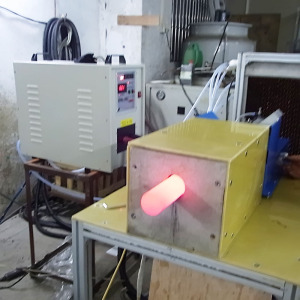

1 Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2 100% Duty cycle, continuous working is allowed at maximum power output.

3Display of heating power and heating current and oscillating frequency;

4 Simple to install, Installation can be done by unprofessional person very easily;

5 Light weight

6 Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

Advantage:

1 More than ten years experience, stable and goods performance

2 CE certificated

3 Copperated with ZHOUDAFU, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

4 Suitable for different bars to forging

5 Two transformer ratios, can match better different length induction coil

6 The Frequency can reach to 1kHz

7 Automatic feeding system, save workers, improve efficiency

1 Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2 100% Duty cycle, continuous working is allowed at maximum power output.

3Display of heating power and heating current and oscillating frequency;

4 Simple to install, Installation can be done by unprofessional person very easily;

5 Light weight

6 Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q: What are the combustion equipments used in industrial boilers?

- The main auxiliary equipments of the general boiler are: upper coal machine, ash blower, blower, draught fan, economizer, feed pump and water treatment unit. Oil boilers are: oil pumps, burners, tanks and so on.

- Q: What is industrial furnace masonry?

- Pre construction and recording shall be carried out on complex and important parts of industrial furnaces,masonry of all kinds of masonry shall be made with staggered joint masonry.

- Q: Why does the burner of industrial furnace burn occasionally?

- The general process for burner ignition, blowing furnace, electric spark ignition, solenoid valve, open the gas in case of delayed spark ignition, detection device detects the flame, the controller accepts signal so that the solenoid valve open, gas continuous normal combustion. However, if the ignition fails or the burner fires, the detector cannot detect the flame, which causes the solenoid valve to close and the burner flameout.

- Q: How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Of course, the difference is like the difference between a hog cap and a 100 story building. See the industrial furnace manual.

- Q: How to use industrial furnace equipment?

- The protection device of the exposed transmission department shall be installed with the correct installation position. The structure is reasonable. The wire rope pulley of the furnace car shall be intact and undamaged. All the pulleys and sprockets on the furnace are in good condition, without defects and flexible in rolling.

- Q: Brief introduction to repair of industrial furnace

- Although the number of industrial furnaces in general machinery plants is not large, the number of large repairs per year accounts for 16%-20% of the total number of repairs for all equipment, and the large repair costs account for about 18%-25% of the total repair cost of all equipment.

- Q: What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

Send your message to us

Induction Forging Furnace (ORD-15KW-300KW)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches