High strength S17400 precipitation hardened martensitic stainless steel round steel

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

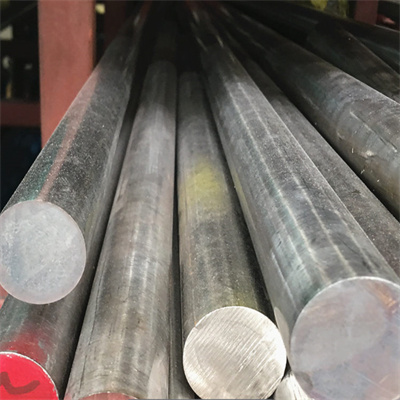

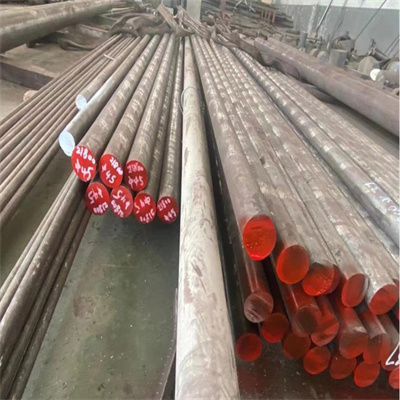

High strength S17400 precipitation hardened martensitic stainless steel round steel

S17400 is a martensitic precipitation hardening stainless steel, also known as 17-4PH. This material is mainly composed of elements such as iron, chromium, nickel, titanium, and copper, and has high strength, high hardness, excellent welding performance, and corrosion resistance. The alloy composition of S17400 makes it excellent in mechanical properties, corrosion resistance, and processability, especially suitable for various industrial fields that require high strength, corrosion resistance, wear resistance, and fatigue resistance. Its applications are very extensive, including but not limited to manufacturing bearings, pump shafts, valves, mechanical seals, aircraft engine components, rocket engine components, ship components, etc. In addition, S17400 is widely used in the field of medical engineering, such as artificial skeletons, dental braces, pacemakers, etc.

Stainless steel round steel belongs to the category of long materials and also to the category of rods. The so-called stainless steel round steel refers to long materials with a uniform circular cross-section, generally about four meters long. It can be divided into light circles and black bars. The so-called light circle refers to a smooth surface that has undergone quasi rolling treatment; The so-called black rod refers to a surface that is black and coarse, directly hot-rolled.

The difference between round steel and other steel bars:

1. The appearance is different. Round steel has a smooth and round shape, without lines or ribs, while other steel bars have grooves or ribs on the surface, resulting in a low bonding force between round steel and concrete, while other steel bars have a high bonding force with concrete.

2. The composition is different. Round steel (first grade steel) belongs to ordinary low-carbon steel, while other steel bars are mostly alloy steel.

3. The strength is different, with round steel having lower strength and other steel having higher strength. That is, round steel with the same diameter can withstand less tensile force compared to other steel bars, but its plasticity is stronger. That is, round steel has greater deformation before being pulled apart, while other steel bars have much smaller deformation before being pulled apart.

Stainless steel round steel has broad application prospects and is widely used in hardware kitchenware, shipbuilding, petrochemicals, machinery, medicine, food, electricity, energy, aerospace and other fields.

Buyer Reading

All products in our store are photographed from real objects, with slight color differences in the pictures. For any product issues, please contact our merchant's after-sales service for assistance! The prices of our products are for reference only. There are many models in different series and prices may vary. Please consult the merchant before placing an order.

Products need to be customized in advance (such as non-standard production and processing). Please consult the merchant before placing an order to see if there is stock available. If customization is required, please confirm the order deadline (to avoid delaying your urgent needs).

- Q: Are steel round bars resistant to abrasion?

- Yes, steel round bars are generally resistant to abrasion due to their hardness and durability.

- Q: What is the hardness of a steel round bar?

- The hardness of a steel round bar may differ depending on the type of steel and the manufacturing process utilized. To measure the hardness of steel, the Rockwell hardness scale is commonly employed. This scale determines the depth of indentation caused by a specific load on a diamond or steel ball. Steel round bars generally exhibit hardness values ranging from approximately 20 to 60 Rockwell C (HRC), with higher values indicating greater hardness. However, it is crucial to acknowledge that the hardness of a steel round bar can also be affected by factors such as heat treatment, alloying elements, and any applied surface treatments. Consequently, it is imperative to refer to the manufacturer or supplier's specified hardness specifications to accurately ascertain the hardness of a steel round bar.

- Q: Can steel round bars be coated with protective finishes?

- Steel round bars can indeed have protective finishes applied to them. Applying protective finishes to steel round bars is a widespread practice aimed at improving their durability and resistance to corrosion. There are several options available for protective finishes, such as galvanizing, powder coating, and epoxy coating, among others. These finishes effectively safeguard the steel bars against rust and deterioration, thus prolonging their lifespan and enabling them to perform well in different environments. The selection of a protective finish depends on various factors, including the intended use of the steel round bars, the extent of exposure to moisture or corrosive substances, and the desired aesthetic appeal.

- Q: What are the differences between the products made of wrought round steel and hot rolled round steel and tested by mechanical testing after heat treatment?

- In comparison, the general longitudinal performance of hot rolled round bar is better than that of transverse or tangential direction, and the difference between the two values is obvious. The banded structure is more obvious in the longitudinal microstructure, and the deformation of non-metallic plastic inclusions is more obvious

- Q: What are the advantages of using steel round bars in construction?

- There are several advantages of using steel round bars in construction. Firstly, steel round bars offer exceptional strength and durability, making them ideal for supporting heavy loads and withstanding harsh weather conditions. Secondly, they are highly resistant to corrosion, ensuring long-lasting and low-maintenance structures. Additionally, steel round bars can be easily customized and shaped to fit various construction needs, allowing for flexibility in design. Lastly, steel round bars are readily available and cost-effective, making them a preferred choice for construction projects.

- Q: Can steel round bars be used for making staircases?

- Yes, steel round bars can be used for making staircases. Steel round bars are commonly used in the construction industry for various applications, including staircase fabrication. They are strong, durable, and provide excellent structural support, making them an ideal choice for staircases. Steel round bars can be used to create the framework and structure of the staircase, providing stability and safety. Additionally, steel round bars can be easily shaped and welded to create different designs and styles for the staircase, allowing for customization and flexibility in the construction process. Overall, steel round bars are a reliable and popular choice for making staircases due to their strength, durability, and versatility.

- Q: What is the difference between a cold-drawn and a polished steel round bar?

- The manufacturing processes and resulting properties of a cold-drawn steel round bar and a polished steel round bar are different. To produce a cold-drawn steel round bar, a hot-rolled steel bar is pulled or drawn through a die or series of dies at room temperature. This reduces its diameter and increases its length. This process imparts specific characteristics to the steel. Cold-drawn steel bars have a smooth and shiny surface, with tight dimensional tolerances and improved mechanical properties. The cold drawing process refines the microstructure of the steel, making it stronger, more uniform, and less prone to defects. These bars are commonly used in applications that require high strength, precision, and resistance to fatigue, such as automotive components, machinery, and tooling. In contrast, a polished steel round bar undergoes a different treatment process. Once the steel bar is formed, it undergoes polishing, which involves grinding or buffing the surface to achieve a smooth and reflective finish. Polished steel bars have a shiny and mirror-like appearance due to the removal of surface imperfections and contaminants. This process is primarily done for aesthetic purposes and does not significantly alter the mechanical properties of the steel. Polished steel round bars are commonly used in decorative applications, architectural designs, and furniture. In conclusion, the main distinction between a cold-drawn and a polished steel round bar lies in their manufacturing processes and intended applications. Cold-drawn bars go through a precise cold drawing process to enhance their mechanical properties, while polished bars undergo surface polishing for an aesthetically pleasing finish.

- Q: Can steel round bars be used for making propeller shafts?

- Yes, steel round bars can be used for making propeller shafts. Steel is a commonly used material for propeller shafts due to its strength, durability, and resistance to corrosion. Round bars, in particular, are often chosen for their shape, which provides optimal strength and load-bearing capabilities. The selection of steel grade and specific properties will depend on the requirements of the propeller shaft, such as the desired length, diameter, and torque capacity. Additionally, other factors like cost, weight, and manufacturability may also influence the choice of steel round bars for propeller shafts.

- Q: How do steel round bars compare to carbon fiber round bars?

- Steel round bars and carbon fiber round bars are materials commonly used in various industries, but they differ in several aspects. Strength and Durability: Steel round bars are renowned for their exceptional strength and durability, enabling them to withstand heavy loads, high temperatures, and harsh environments. On the other hand, carbon fiber round bars are also strong but generally not as strong as steel bars. However, they have a remarkable strength-to-weight ratio, making them a popular choice when weight reduction is crucial. Weight: One noticeable difference is the weight. Steel round bars are significantly heavier compared to carbon fiber round bars. This weight disparity often makes carbon fiber bars more preferable in industries where reducing weight is important, like aerospace and automotive sectors. The use of lighter bars can contribute to improved fuel efficiency, increased speed, and enhanced maneuverability. Corrosion Resistance: Steel round bars are susceptible to corrosion, especially when exposed to moisture and specific chemicals. Regular maintenance and protective coatings are often necessary to prevent rusting. Conversely, carbon fiber round bars possess inherent corrosion resistance. This property makes them valuable in environments where corrosion is a concern, such as marine applications. Flexibility and Stiffness: Steel round bars are generally stiffer and less flexible compared to carbon fiber round bars. This characteristic is advantageous in applications where rigidity and structural integrity are crucial, like construction and heavy machinery. In contrast, carbon fiber round bars offer higher flexibility and can be engineered to have varying levels of stiffness, making them suitable for applications requiring vibration damping or enhanced shock absorption. Cost: In terms of cost-effectiveness, steel round bars usually have the upper hand. Steel is widely available, and its production costs are relatively low. Carbon fiber, however, is more expensive to produce due to the complex manufacturing process and the cost of raw materials. Consequently, carbon fiber round bars tend to be pricier and are limited to industries where their unique properties justify the increased costs. In conclusion, steel round bars and carbon fiber round bars have their own advantages and disadvantages. Steel bars offer exceptional strength, durability, and cost-effectiveness, while carbon fiber bars excel in weight reduction, corrosion resistance, flexibility, and stiffness. The choice between the two depends on the specific requirements of the application, including factors such as load-bearing capacity, weight reduction, corrosion resistance, and cost considerations.

- Q: Can steel round bars be used in outdoor applications?

- Yes, steel round bars can be used in outdoor applications. Steel is a durable and corrosion-resistant material, making it suitable for various outdoor environments. However, it is essential to choose the right type of steel and apply appropriate protective coatings to ensure long-term performance and prevent rusting.

Send your message to us

High strength S17400 precipitation hardened martensitic stainless steel round steel

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords