Carbon Structural Steel Square Bars ASTM A36

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Square Bars ASTM A36

Product Specification

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Cu |

| ASTM A36 | ≤0.25 | ≤0.40 | 0.80-1.20 | ≤0.050 | ≤0.040 | ≥0.30 | ≥0.20 |

2, Diameter: 9mm, 9.8mm, 10mm, 12mm, 12.5mm, 13mm, 15mm, 15.87mm, 16mm, 19mm, 20mm, 22mm,

25mm, 25.4mm, 28mm, 38mm, 50mm, 51.5mm, 53mm, 65mm, 75mm, 100mm

Application

1. Manufacturing of mechanical parts

2. Welding structure building

3. Bridge engineering with higher quality requirements

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

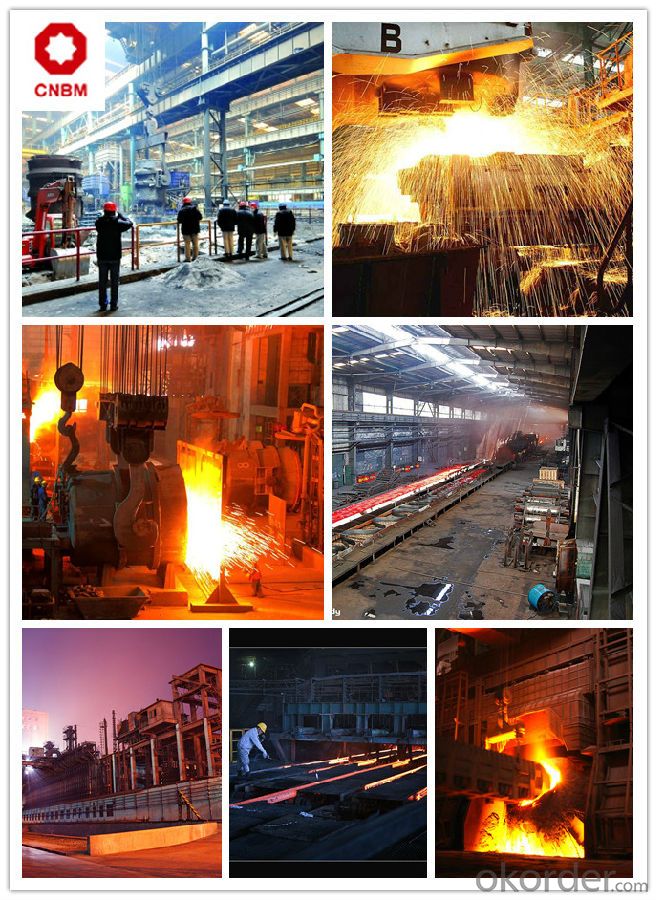

Product Show

Work Shop

About Us

- Q:Can steel round bars be used for making transmission towers?

- Yes, steel round bars can be used for making transmission towers. Steel round bars are often used in the construction industry due to their strength, durability, and versatility. Transmission towers require materials that can withstand extreme weather conditions, support heavy loads, and provide structural stability. Steel round bars are able to meet these requirements, making them a suitable choice for the construction of transmission towers. Additionally, steel round bars can be easily fabricated and welded, allowing for efficient construction and installation of transmission towers.

- Q:20 round bars are of several grades

- 20 round bars may be grade two steel.

- Q:What are the different types of steel round bar machining processes?

- There exist various steel round bar machining processes, each with distinct characteristics and applications. Some of the most prevalent types are as follows: 1. Turning: By rotating the steel round bar against a cutting tool, material is removed to achieve the desired shape. Turning is frequently employed to create cylindrical shapes or eliminate excess material from the surface. 2. Drilling: This machining process involves the creation of holes in the steel round bar using a rotating cutting tool. Drilling is commonly utilized to generate holes for bolts or other fasteners. 3. Milling: A versatile machining process, milling entails the removal of material from the surface of the steel round bar using a rotating cutting tool. This technique can be employed to fashion intricate shapes, slots, or grooves. 4. Grinding: Material is removed from the surface of the steel round bar using an abrasive wheel in the grinding process. It is often employed to achieve a smooth finish or eliminate imperfections on the surface. 5. Boring: Boring enlarges an existing hole in the steel round bar using a cutting tool. It is frequently used to create larger diameter holes or achieve greater precision. 6. Knurling: In this machining process, ridges or grooves are created on the surface of the steel round bar, often to enhance grip or create a decorative effect. 7. Thread cutting: External or internal threads are created on the surface of the steel round bar using the process of thread cutting. This technique is commonly used to create threaded holes or threaded fasteners. These examples merely scratch the surface of the diverse steel round bar machining processes. Each process possesses unique advantages and limitations, and the selection of which process to employ depends on the specific requirements of the application.

- Q:Can steel round bars be used in the manufacturing industry?

- Certainly! In the manufacturing industry, steel round bars find extensive utility. These bars exhibit great versatility and are extensively employed across diverse manufacturing processes. Machining, forging, welding, and fabrication all benefit from their usage, facilitating the creation of an array of products, including machinery parts, tools, automotive components, construction materials, and more. These round bars boast exceptional robustness, durability, and remarkable wear resistance, rendering them highly suitable for arduous manufacturing applications. Furthermore, manufacturers can select from a range of grades and sizes, enabling them to opt for the most appropriate option tailored to their specific needs.

- Q:What are the advantages of using steel round bars in construction?

- There are several advantages of using steel round bars in construction: 1. Strength and Durability: Steel round bars are known for their exceptional strength and durability. They have a high tensile strength, which means they can withstand heavy loads and provide robust support. This makes them ideal for construction projects that require structural integrity and stability. 2. Versatility: Steel round bars come in various sizes and grades, offering versatility in construction. They can be easily shaped, bent, and welded to fit specific design requirements, making them suitable for a wide range of applications. Whether it's for building frameworks, reinforcement in concrete structures, or even decorative elements, steel round bars can be tailored to meet different project needs. 3. Cost-effectiveness: Steel round bars offer cost-effectiveness in construction due to their long lifespan and low maintenance requirements. They are resistant to corrosion, weathering, and pests, which reduces the need for frequent repairs or replacements. Additionally, their strength allows for the utilization of lighter construction materials, leading to potential cost savings in the overall project. 4. Fire Resistance: Steel round bars have excellent fire-resistant properties, making them a safe choice for construction. They do not burn, melt, or emit toxic fumes under high temperatures, which can be crucial in preventing the spread of fire and ensuring the safety of occupants. 5. Sustainability: Steel is a highly sustainable material as it is 100% recyclable. Using steel round bars in construction contributes to reducing environmental impact by minimizing waste and conserving natural resources. Additionally, the process of recycling steel requires less energy compared to manufacturing it from raw materials, making it an eco-friendly choice. 6. Availability and Quality Control: Steel round bars are readily available in the market, making them easily accessible for construction projects. Moreover, their production undergoes strict quality control measures, ensuring consistent and reliable material properties. This guarantees the structural integrity and safety of the constructed buildings or infrastructures. In conclusion, the advantages of using steel round bars in construction include their strength, versatility, cost-effectiveness, fire resistance, sustainability, availability, and quality control. These attributes make them a popular choice for builders and engineers seeking reliable and efficient materials for their construction projects.

- Q:Can steel round bars be used in the production of flanges?

- Flanges in the production process can utilize steel round bars. Steel round bars, commonly used as raw materials, can be machined, forged, or rolled into the desired flange shape. The production of flanges benefits from steel round bars due to their high strength, durability, and resistance to corrosion. Additionally, they can be easily fabricated and machined to meet specific size and dimensional needs. Various industries, including oil and gas, petrochemical, power generation, and construction, widely employ steel round bars for the production of flanges. These flanges are essential in connecting pipes or equipment within piping systems.

- Q:4145H round steel is equivalent to the domestic brand?

- Round steel is a solid strip of steel whose cross section is round. Its specifications are expressed in diameter, in units of millimeters (mm), such as "50mm", which means a diameter of 50 millimeters of round steel. Round bar is divided into three parts: hot rolling, forging and cold drawing. Standard Specification for hot rolled round steel is 5.5-250 mm. Of which: 5.5-25 mm small round bars are mostly supplied by straight strips. They are used as reinforcing bars, bolts and various mechanical parts; round steel larger than 25 millimeters, mainly used for making machines.

- Q:What is the difference between a bright and a cold finished steel round bar?

- Two distinct types of steel bars are the bright steel round bar and the cold finished steel round bar. These bars differ in their manufacturing processes and resulting characteristics. The bright steel round bar, also known as a turned or polished bar, undergoes a process called turning or polishing. During this process, a lathe machine rotates the rough steel bar while a cutting tool removes its outer layer. This results in a smooth and shiny surface, enhancing the bar's appearance, dimensional accuracy, and surface finish. Bright steel round bars are commonly used in applications where aesthetics and a high-quality surface finish are important, such as architectural components, decorative items, and certain automotive parts. On the other hand, the cold finished steel round bar undergoes a different manufacturing process called cold drawing or cold rolling. This process involves passing the hot-rolled steel bar through a series of dies at room temperature. As a result, the bar's diameter is reduced while its length is increased. This cold working process improves the mechanical properties of the steel bar, including increased tensile strength, improved yield strength, and enhanced dimensional accuracy. Cold finished steel round bars are often used in applications that require high strength and precision, such as shafts, gears, bolts, and tools. In conclusion, the main distinction between the bright steel round bar and the cold finished steel round bar lies in their manufacturing processes and resulting characteristics. The bright steel round bar is turned or polished to achieve a smooth and shiny surface, while the cold finished steel round bar undergoes cold drawing or rolling to enhance its mechanical properties and dimensional accuracy. The choice between these two types of steel bars depends on the specific requirements of the application, such as the need for aesthetics, surface finish, strength, or precision.

- Q:Can steel round bars be used in the manufacturing of consumer goods?

- Consumer goods manufacturing can make use of steel round bars. Steel is a durable and versatile material that finds wide application across industries, including the production of consumer goods. Steel round bars can be molded, cut, and shaped into various components or parts that are required for items like furniture, appliances, tools, and machinery. The strength and resilience of steel make it a perfect choice for consumer goods that demand robust and long-lasting materials. Moreover, steel can be easily customized and finished with coatings or treatments to enhance its appearance or protect it from corrosion, thereby making it even more suitable for use in consumer goods. In summary, the usage of steel round bars is common in consumer goods manufacturing due to their dependable nature, versatility, and ability to provide the desired quality and functionality.

- Q:How are steel round bars used in the manufacturing of agricultural machinery?

- Steel round bars are commonly used in the manufacturing of agricultural machinery as they provide strength, durability, and flexibility. These bars are often used to construct various components such as axles, shafts, and pins, which play a crucial role in supporting and transmitting power within the machinery. The high tensile strength of steel round bars allows them to handle heavy loads and withstand harsh operating conditions, ensuring the reliability and longevity of the agricultural equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Structural Steel Square Bars ASTM A36

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords