All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Steel Wire RodView More

Steel CoilsView More

Steel ProfilesView More

Steel PipesView More

Stainless SteelView More

TinplateView More

Special SteelView More

Steel SheetsView More

Steel RebarsView More

Steel StripsView More

Hot Rolled SteelView More

Cold Rolled SteelView More

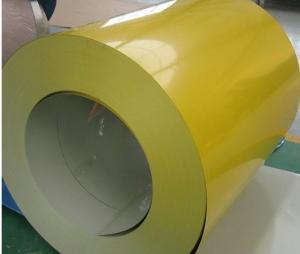

Pre-painted SteelView More

Seamless Steel PipeView More

Welded Steel PipeView More

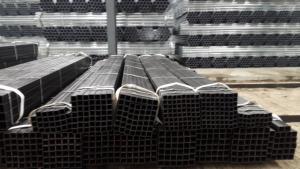

Hollow Steel TubesView More

Galvanized PipeView More

Stainless Steel CoilView More

Stainless Steel SheetView More

Stainless Steel PlateView More

Stainless Steel StripsView More

Electrolytic Tinplate CoilView More

Electrolytic Tinplate SheetView More

Stainless Steel RebarsView More

Q & A

How has the technology of steelmaking evolved over the years?

The technology of steelmaking has evolved significantly over the years. Initially, the process involved smelting iron ore in a furnace, followed by manual forging to remove impurities. However, the Industrial Revolution brought about the development of the Bessemer process in the mid-19th century, which allowed for the mass production of steel. This involved blowing air through molten iron to remove impurities and create a purer form of steel. Later innovations, such as the open-hearth process and the electric arc furnace, further improved steel production by allowing for greater control over the composition and quality of the steel. Today, advanced technologies like basic oxygen steelmaking and continuous casting methods have further enhanced efficiency, productivity, and overall quality in the steelmaking industry.

What are the challenges in designing earthquake-resistant steel structures?

One of the main challenges in designing earthquake-resistant steel structures is ensuring the flexibility and ductility of the building. Steel structures need to be able to absorb and dissipate the energy generated by an earthquake, and this requires careful consideration of the material properties and structural design. Additionally, the design needs to account for the dynamic nature of earthquakes, including the varying frequencies and amplitudes of ground motion. Furthermore, the construction and detailing of steel structures must be precise and accurate to ensure proper load transfer and avoid potential weak points. Overall, the challenges lie in balancing the strength and stiffness of the structure with its ability to withstand and absorb seismic forces.

How is steel made?

Steel is made through a process called smelting, where iron ore is heated in a blast furnace with carbon. This combination creates molten iron, which is then refined by removing impurities like sulfur and phosphorus. To turn it into steel, controlled amounts of carbon and other elements are added, and the mixture is further refined and shaped through various methods like rolling or casting.

Wholesale Steel from supplier in Indonesia

With our sales team in Indonesia, we ensure a smooth and hassle-free procurement process for our customers. Whether you need steel pipes, plates, or structural steel, we have a wide selection of high-quality products to meet your specific requirements.

In addition to offering competitive prices and timely delivery, we also provide comprehensive technical support. Our team of experts is always ready to assist you in choosing the right steel products for your projects and providing valuable advice on their installation and maintenance.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring that we can source the best quality steel products at the most competitive prices. Our strong relationship with manufacturers allows us to offer a wide range of options and customization to meet your specific needs.

We understand the challenges and complexities of the Indonesian market, and we have extensive experience in navigating its unique business landscape. Our local knowledge and understanding of regulations and procedures enable us to provide seamless services to our customers.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships. We believe in forging strong relationships based on trust, reliability, and mutual success. Our dedicated team is committed to meeting your steel procurement needs efficiently and effectively, ensuring that you receive the best products and services every time.

Choose us as your trusted partner for all your steel procurement needs in Indonesia. Contact us today for sales, quotations, and technical support, and let us support your projects with our expertise and reliability.

In addition to offering competitive prices and timely delivery, we also provide comprehensive technical support. Our team of experts is always ready to assist you in choosing the right steel products for your projects and providing valuable advice on their installation and maintenance.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring that we can source the best quality steel products at the most competitive prices. Our strong relationship with manufacturers allows us to offer a wide range of options and customization to meet your specific needs.

We understand the challenges and complexities of the Indonesian market, and we have extensive experience in navigating its unique business landscape. Our local knowledge and understanding of regulations and procedures enable us to provide seamless services to our customers.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships. We believe in forging strong relationships based on trust, reliability, and mutual success. Our dedicated team is committed to meeting your steel procurement needs efficiently and effectively, ensuring that you receive the best products and services every time.

Choose us as your trusted partner for all your steel procurement needs in Indonesia. Contact us today for sales, quotations, and technical support, and let us support your projects with our expertise and reliability.