All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the applications of aluminum coils in the production of transformer windings?

Aluminum coils in the production of transformer windings offer various advantages such as lightweight, high electrical conductivity, and cost-effectiveness. These coils are commonly used in low voltage and distribution transformers, where their reduced weight facilitates easier transportation and installation. Additionally, aluminum's excellent electrical conductivity allows for efficient power transmission and distribution. Moreover, using aluminum coils in transformer windings helps to reduce overall production costs without compromising performance, making it a popular choice in the industry.

How are aluminum coils used in the automotive body panels?

Aluminum coils are commonly used in the automotive industry for the production of body panels. These coils are typically rolled and shaped into specific sizes and profiles before being stamped or molded into the desired shape of the body panel. The use of aluminum coils in automotive body panels offers several advantages, including lightweight construction, improved fuel efficiency, better handling, and increased corrosion resistance. Additionally, the malleability and formability of aluminum allow for intricate designs and complex shapes, providing flexibility for automakers in creating aesthetically pleasing and aerodynamic body panels.

Can aluminum coils be used in the production of advanced robotic systems?

Yes, aluminum coils can be used in the production of advanced robotic systems. Aluminum is a lightweight and durable material that offers excellent conductivity, making it suitable for various applications in robotics. It can be used for motor winding, electromagnetic coils, and other components that require efficient electrical performance. Additionally, aluminum's corrosion resistance and cost-effectiveness make it a viable choice for manufacturing advanced robotic systems.

How are aluminum coils typically packaged for shipping?

Aluminum coils are typically packaged for shipping by being tightly wound and secured with steel strapping or nylon bands. They are then placed on wooden pallets and covered with protective wrapping such as plastic or shrink wrap. This packaging ensures that the coils remain secure and protected during transportation to prevent any damage or deformation.

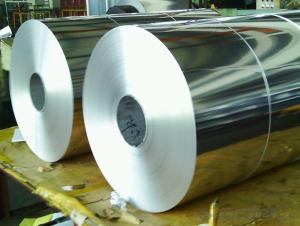

Wholesale Aluminum Coils from supplier in Indonesia

Our team of experts is dedicated to understanding your specific requirements and providing customized solutions to meet your needs. Whether you are in the construction, automotive, or packaging industry, we have the right Aluminum Coils products to suit your application.

With our strong supply chain network and strategic partnerships with top manufacturers, we ensure that you receive high-quality Aluminum Coils at competitive prices. Our efficient logistics capabilities enable us to deliver your orders promptly and reliably to any location in Indonesia.

In addition to our sales services, we also offer comprehensive technical support, including product recommendations, specifications, and installation guidance. Our experienced engineers are available to assist you throughout the entire project, ensuring its success.

We understand the importance of reliable customer service, and our dedicated sales team is always ready to assist you with any inquiries or concerns you may have. We strive to build long-term relationships with our customers by providing exceptional service and exceeding their expectations.

Choose us as your trusted supplier of Aluminum Coils in Indonesia and experience the benefits of working with a reputable company backed by a global leader. Contact us today for a quote or to discuss your specific requirements.

With our strong supply chain network and strategic partnerships with top manufacturers, we ensure that you receive high-quality Aluminum Coils at competitive prices. Our efficient logistics capabilities enable us to deliver your orders promptly and reliably to any location in Indonesia.

In addition to our sales services, we also offer comprehensive technical support, including product recommendations, specifications, and installation guidance. Our experienced engineers are available to assist you throughout the entire project, ensuring its success.

We understand the importance of reliable customer service, and our dedicated sales team is always ready to assist you with any inquiries or concerns you may have. We strive to build long-term relationships with our customers by providing exceptional service and exceeding their expectations.

Choose us as your trusted supplier of Aluminum Coils in Indonesia and experience the benefits of working with a reputable company backed by a global leader. Contact us today for a quote or to discuss your specific requirements.