3003 1060 Corrugated Aluminium Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of 3003 1060 Corrugated Aluminium Roofing Sheet

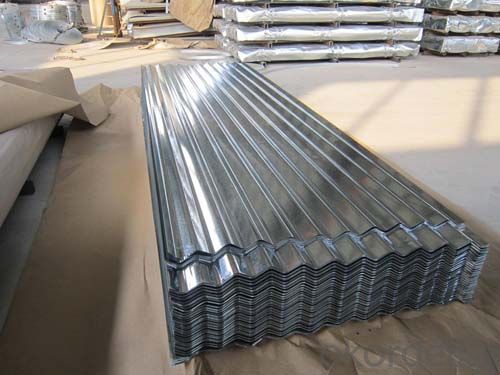

name:corrugated aluminium sheet

alloy:1000,3000

thickness:0.4mm~1.5mm

width range: 1000mm-1500mm

2. Description of 3003 1060 Corrugated Aluminium Roofing Sheet

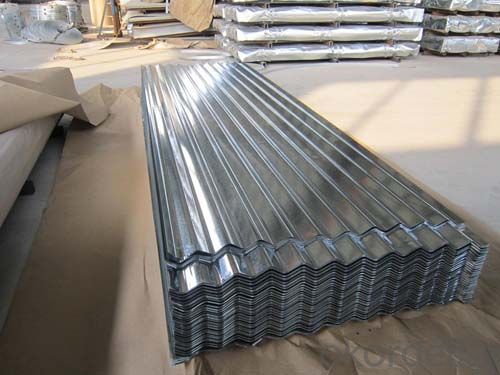

Aluminium Corrugated sheet are rippled metal sheets, primarily used at roofing, decking, and siding. Aluminum Corrugated sheet is tough, light weight, weather resistant and practical. We can produce aluminum corrugated roofing, siding, decking, and flooring for any application.

3. Package and shipping of 3003 1060 Corrugated Aluminium Roofing Sheet

standard export package or as per customer request

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

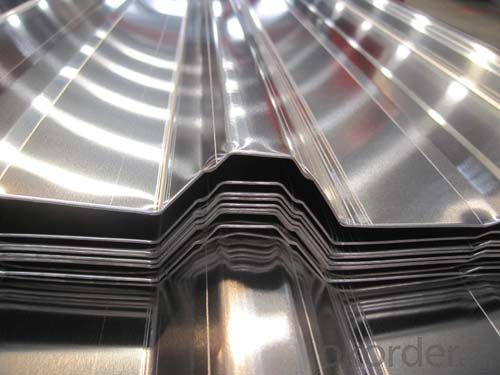

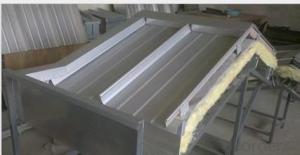

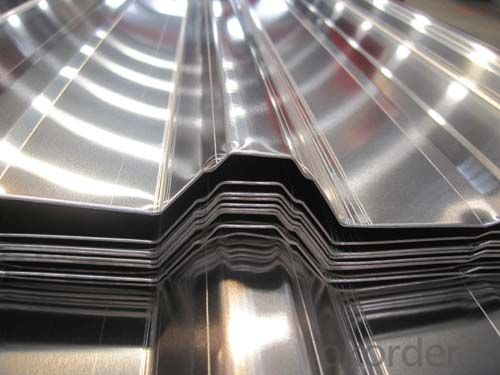

5. Image of 3003 1060 Corrugated Aluminium Roofing Sheet

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

8. Key Specifications/Special Features

1. Aluminum roofing sheets 2. 3003, h44. 3. Color coated as ral color chart. 4. Widely used as ware, garage roofing sheets. 3003, h44 aluminum roofing sheets can be color coated as ral color chart. It's the most widely used roofing materials in warehouse, garage for roofing sheets. We have many customers like in affrica,. During the entire production process of aluminium coating sheet from pre-treatment to finished product, we use international famous quality raw and auxiliary materials, for example aluminum sheets from the famous xinan aluminum industry and some other famous aluminum industry in china, pre-treatment made of ... With the famous germany henkel & chemtell from germany, above 70% pvdf from ppg co.,usa and the polyester coating from sweden becker industrial coating co. With the most advanced equipment and production technology, as well as top raw made of ... Brands, we produce high-quality and reliable colorful aluminium coating sheet. Theyve been widely used on the high-grade aluminum composite panel industry, now we take a lions market share and become one of the largest manufacturers in the face of the earth. Specification:. Coating type: pe (polyester resin) made of ... And pvdf (polyvinylidene fluoride) made of ... . Thickness: 0.2 ~ 1.2 mm,. Width: 800 ~ 1520 mm,. Annual production capacity: 8000 tons.

- Q:Can the aluminum sheets be custom-cut to specific dimensions?

- Yes, the aluminum sheets can be custom-cut to specific dimensions.

- Q:how to connect copper pipe and aluminum sheet?

- it depends on the size and requirement, we can use ultrasonic wave rolling welding to connect copper pipe and aluminum sheet.for example, solar energy radiator-fan contains connection of copper pipe and copper sheet, ultrasonic wave rolling welding equipment is used here.ultrasonic wave welding of metals is suitable for the welding of copper to copper, copper to aluminum and aluminum to aluminum.

- Q:Can aluminum sheets be embossed or engraved?

- Aluminum sheets have the capability to be embossed or engraved. The act of embossing entails the formation of a raised design or pattern on the aluminum sheet's surface, whereas engraving involves the cutting or etching of a design into the surface. These techniques are applicable for incorporating decorative or functional elements into aluminum sheets. In numerous industries, such as automotive, aerospace, signage, and architectural applications, embossed or engraved aluminum sheets are commonly employed. The process of embossing or engraving aluminum sheets typically necessitates the utilization of specialized machinery or tools to achieve the desired design.

- Q:Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- Aluminum Oxide is put together from aluminum and oxygen. A quick look at the periodic table tells you that Al has a +3 charge, while O has a -2 charge. Thus the formula must be Al2O3. Now, the atomic mass of Al is 26.982, and of O 15.999. This means that there is that many grams of each in one mole of each respective element. Thus the formula Mass of Al2O3 is 2(26.982)+3(15.999) = 101.961 g Al2O3. There are 2 mols of Al, so 2(26.982) = 53.964 g Al per the formula mass (53.964/101.961). Now that you have a ratio for the amount of Al in Al2O3, simply multiply it by the mass of aluminum oxide you have to get the mass of Aluminum out. Thusly: (53.964/101.961) x 125g = 66.157 g Al Ta-da!

- Q:Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q:What are the different types of surface treatments for aluminum sheets in the marine industry?

- Some of the different types of surface treatments for aluminum sheets in the marine industry include anodizing, powder coating, chromate conversion coating, and painting.

- Q:how to process 0.3mm hole on aluminum material?

- punching wire-electrode cutting

- Q:Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is lightweight, resistant to corrosion, and can be easily shaped into cans. It also provides a protective barrier against light and air, ensuring the quality and freshness of the beverages inside.

- Q:What are the weight considerations when using aluminum sheets?

- When using aluminum sheets, weight considerations are important due to the lightness of aluminum. It is crucial to determine the thickness and size of the sheet based on the intended application to ensure structural integrity and proper load-bearing capacity. Additionally, the weight of aluminum sheets may affect transportation, installation, and overall handling requirements.

- Q:Are aluminum sheets suitable for HVAC ductwork?

- Yes, aluminum sheets are suitable for HVAC ductwork. Aluminum is a popular choice for ductwork due to its lightweight and durable nature. It is corrosion-resistant, which is important in HVAC systems where moisture and condensation can be present. Aluminum ductwork also offers good thermal conductivity, allowing for efficient heat transfer. Additionally, aluminum sheets are easy to work with, making installation and maintenance relatively simple. Overall, aluminum sheets are a reliable choice for HVAC ductwork, providing long-lasting performance and energy efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3003 1060 Corrugated Aluminium Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords