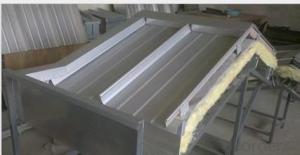

Color Aluminum Pyramid Corrugated Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COLOR COATED ALUMINUM COIL

Product Description:

CNBM uses the advanced Roller Coating Technology, Digtal color print and numberous controlling position technology, degrease, clean, chromated on single/duplicate surface of the aluminium coil. Then wooden Veins & stone Veins come out lively. It has outstanding advantage.

You can use that roller coils for ceiling panel, aluminium panel and honeycomb panel for decoration. For several years' development and design.

PE and PVDF coating.

Aluminium alloy 1100,3003,3105,5005 and others.

Diamond Embossed coil and anti-scratch coil are available.

Product Usage:

1) exterior applications: wall cladding, facades, roofs and canopied, tunnels, column covers or renovations.

2) Interior application: wall cladding, ceilings, bathrooms, kitchens and balconies.

3) Advertisement and market applications: display platforms, signboards, fascias and shop fronts.

4) Transport and industrial applications.

Specification:

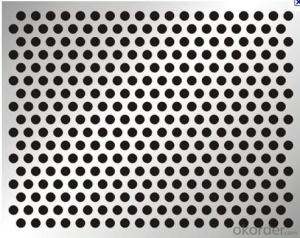

1) Alloy:1100, 3003,3005,3105,5005 and others

2) Thickness:0.02-3.0mm.

3) Width: 50-1500mm.

4) Coating: PE coat

PVDF coat

5) Color standard: E<2 or unperceivable by eye

6) Pencil hardness: >2HB

7) Coating Adhesive: Not lower than first grade impact: no crack(50kg/cm, ASTMD-2794:1993)

8) Buketon: >100 times

9) Boiling point: no distortion and color change

10) Packing: Export standard: Packed in wooden case, wrapped with Foam, Plastic Membrane and Kraft paper

- Q: Are aluminum sheets suitable for artistic sculptures?

- Aluminum sheets, indeed, prove to be a suitable choice for artistic sculptures. Boasting versatility, aluminum offers numerous benefits for sculpting endeavors. First and foremost, its lightweight nature makes it easier for artists to handle and manipulate. This quality grants them the ability to fashion intricate and detailed sculptures without compromising on structural integrity. Moreover, aluminum possesses high malleability, allowing it to be molded into diverse forms and contours. This grants artists the freedom to experiment with various designs and achieve their desired artistic expression. Additionally, aluminum's resistance to corrosion and weathering makes it an ideal material for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and maintain its aesthetic appeal over time. Furthermore, aluminum sheets can be effortlessly welded or joined together, enabling artists to create larger and more intricate sculptures. All in all, aluminum sheets furnish artists with a flexible and long-lasting material that nurtures creativity and guarantees longevity in their sculptural masterpieces.

- Q: are there any carbonated mineral water that are produced in aluminium cans.

- Aluminium cans have an oxide covering on them so the reaction between them and the carbonated water is so little if any that it can't be noticed. Aluminium is also not so high on the reactivity series

- Q: What are the standard dimensions of aluminum sheets?

- The standard dimensions of aluminum sheets vary depending on the specific industry and application. However, there are some common sizes that are widely available. For general purposes, the most common standard dimensions for aluminum sheets are 4 feet by 8 feet (1219mm x 2438mm) and 4 feet by 10 feet (1219mm x 3048mm). These sizes are often referred to as "full sheets" and are commonly used in construction, manufacturing, and signage industries. In addition to full sheets, aluminum sheets are also available in smaller sizes such as 2 feet by 4 feet (609mm x 1219mm) and 2 feet by 8 feet (609mm x 2438mm). These smaller sheet sizes are often used for DIY projects, crafts, and hobbyist applications. It's important to note that while these dimensions are considered standard, aluminum sheets can be custom cut to specific sizes and shapes to meet individual project requirements. This allows for greater flexibility and versatility in various industries. Ultimately, the choice of aluminum sheet dimensions depends on the specific project needs, industry standards, and personal preferences.

- Q: I need to find 3 elements for my science hw tonight. I was wondering if aluminum foil is a pure element. And also I was wondering if anyone had any ideas of what is a pure element (not a compound or an alloy). Thanks!!!!

- www.okorder

- Q: Can aluminum sheet be used for reflective surfaces?

- Indeed, reflective surfaces can be achieved with the use of aluminum sheet. Renowned for its exceptional reflectivity, aluminum is widely preferred for an array of applications that call for reflective surfaces. By skillfully polishing aluminum sheets, they can attain a remarkable luster, enabling them to reflect light and produce a mirror-like effect. Consequently, they prove to be the perfect choice for applications such as lighting fixture reflectors, solar panels, mirrors, and decorative purposes. Moreover, owing to its reflective properties, aluminum is an ideal material for situations necessitating heat reflection, including thermal insulation and roofing materials. In summary, aluminum sheets offer versatility and effectiveness when it comes to generating reflective surfaces.

- Q: who knows the ceiling technology of aluminum sheet?

- Construction technology of ceiling aluminum sheet: (1) firstly check keel’s quality, the straight shape and uniformly forced state of boom, control the keel’s gap within 500mm, reduce the gap according to design requirement under humid environment. The lower surface of keel is smooth without a sense of bearing down, main device is closely connected with accessories, it can be bound after being confirmed qualified.(2) we should break the board along the cutting line and ensure the margin of cutting board straight and square without any chipping or arris defect. (3) while placing and fixing the board, we can place edge of aluminum-plastic panel(encapsulated edge) in the vertical direction of supporting keel, there is a phenomena of hanging. Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. You can start from a plate angle or middle position, and don’t place them at the same time. Slab joint should be straight and in the same width, without break joint. (4) in the process of joint, Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. And the butt joint should be stagger, the butt joint can’t be connected on the same keel. When you use doubling plate, the joints of the second layer board and the first layer board can’t be connected with the same keel, double-deck gypsum board should be staggered joints.

- Q: What is the bending radius of aluminum sheets?

- The bending radius of aluminum sheets is influenced by several factors, including the sheet thickness, the type of aluminum alloy used, and the bending method employed. In general, aluminum sheets with a thickness of 1mm or less can be bent without cracking if the radius is equal to the thickness of the sheet. For thicker aluminum sheets, it is necessary to have a bending radius that exceeds the thickness of the sheet in order to prevent cracking or fracturing. As a rule of thumb, aluminum sheets with a thickness ranging from 1mm to 6mm should have a bending radius at least 1.5 times the sheet thickness. For instance, a 3mm thick aluminum sheet should have a minimum bending radius of 4.5mm. It is important to note that these guidelines are approximate and can vary depending on the specific aluminum alloy and temper utilized. Additionally, different bending processes, such as air bending, bottoming, or coining, may require different bending radii. To obtain precise bending radius requirements for specific applications of aluminum sheets, it is advisable to consult the manufacturer's specifications or seek professional advice.

- Q: How do you form curves or shapes in aluminum sheets?

- There are several methods to form curves or shapes in aluminum sheets. One common technique is called bending, where the sheet is clamped and then gradually bent using a mechanical press brake or a hammer. Another method is called roll forming, which involves passing the aluminum sheet through a series of rollers to achieve the desired shape. Additionally, aluminum sheets can be molded or pressed into curves or shapes using specialized tools or dies.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- You said new home. Aluminum hasn't been used in house wiring for many years. It is now only used for the main service wires coming in to the panel. Shop vacs can trip 15 amp bedroom circuits. I think you need to call in an electrician if your dad reset all the breakers. Have him do the exhaust fan too. Let your brother help mom with the cleaning. Forget about doing your own wiring or replacing things yourself. Hire an electrician. The firefighters will thank you.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

Color Aluminum Pyramid Corrugated Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords