Industrial Aluminum Sheets for Corrugated Aluminum Roofing Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

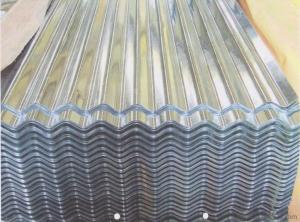

1. Specifications of Aluminum Sheets For Corrugated Aluminum Roofing Sheets

Alloy: 1100, 1050, 1060, 3003

Temper: H18

Thickness: 0.2-1.5mm

Width Before Pressed: 1000mm

Wave shape: Trapezia/sine wave

2. Application of Aluminum Sheets For Corrugated Aluminum Roofing Sheets

It can be widely used in the decoration for construction field, electronics and household electrical appliance field, transportation field and packing field, ect.

3. Feature of Aluminum Sheets For Corrugated Aluminum Roofing Sheets

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum Sheets For Corrugated Aluminum Roofing Sheets

6. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- Pie:- Shepherd’s 500g (1lb) Minced Lamb.(purple meat will do) a million great onion. 2 purple meat cubes. a million ? C Water. ? C Frozen peas. ? C Diced carrot. 2T Cornflour. 4C Potato. (mashed) ? C Grated cheese. Season to flavor. Chop onion and brown gently, upload mince and brown. disintegrate in the inventory cubes, upload 1C of water, carrots and peas. Simmer for 10 minutes Thicken with cornflour mixed with ? cup water and prepare dinner for a jiffy. opened up in a pie or baking dish and canopy with mashed potatoes. Sprinkle with cheese and bake at 190C (375F) for 20 minutes till the potato has browned and the cheese has melted. If made with purple meat it would be referred to as Cottage Pie.

- Q: What is the typical hardness of aluminum sheets?

- The typical hardness of aluminum sheets can vary depending on the specific alloy and tempering process used, but it generally falls within the range of 40-70 on the Rockwell B scale.

- Q: I need to know what composite bats do and how (or if) they are better than aluminum bats.

- This Site Might Help You. RE: What is the difference between composite bats and aluminum bats? I need to know what composite bats do and how (or if) they are better than aluminum bats.

- Q: I know that aluminum doesn't belong in the human body. As a canister to hold liquids which will be consumed later, is aluminum good or bad to use?

- In my opinion.... Typical plastic bottles with bpa are the worst for you. Aluminum bottles are a step up and great for the environment since aluminum does not require pollutive materials to make and the material itself is not hazardous to the environment like plastic is. Hard plastic bottles without bpa and other harmful materials/chemicals is better for your health as long as it is not exposed to the sun or heat. Stainless steal containers are great to use, but what can be even better?. Water containers that are made out of animals. Example: animal skin, goat bladder. Animal bladders do a great job holding in animal urine, why not use them to hold drinkable water?? You also do not have to worry about any harmful product getting inside your body since animals are 100% biodegradable and they are natural to the environment. When I deploy to Iraq, im going to find a goat and rip out its bladder! Then im going to convert it into a water container for my camelbak!

- Q: Are aluminum sheets suitable for marine applications?

- Indeed, aluminum sheets prove to be a fitting option for marine applications. Owing to its exceptional resistance to corrosion and durability in marine settings, aluminum emerges as a widely employed material in the maritime sector. Notably, its lightweight yet robust nature renders it an ideal selection for diverse purposes, encompassing boat construction, ship hulls, decks, and other marine structures. Moreover, aluminum boasts a commendable strength-to-weight ratio, thereby enhancing fuel efficiency and reducing operational expenses. Its capacity to endure the harsh conditions of saltwater, coupled with its minimal maintenance requirements, further solidifies its popularity in marine applications. All in all, aluminum sheets serve as a dependable and efficient material for employment in the marine industry.

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are versatile in construction due to their strength, durability, and lightweight properties. They are used for roofing and cladding to provide weather resistance and aesthetic appeal. Aluminum sheets are also utilized in the fabrication of window frames and doors for their strength and thermal efficiency. They are employed in the construction of scaffolding and temporary structures due to their lightweight and ease of assembly. Additionally, aluminum sheets are used in the manufacturing of facades, canopies, and decorative elements for their modern look and low maintenance requirements.</p>

- Q: How do i prepare the aluminium sheet to paint with oils on it?Do I have to buy special aluminium or any kind will work?

- Hi, okorder /

- Q: What are the different methods of surface treatment for adhesive bonding of aluminum sheet?

- There are several methods of surface treatment for adhesive bonding of aluminum sheet, including mechanical cleaning, chemical cleaning, anodizing, and conversion coating. Mechanical cleaning involves removing dirt, grease, and oxide layers through methods such as sanding, grinding, or brushing. Chemical cleaning uses solvents or detergents to remove contaminants and prepare the surface for bonding. Anodizing forms a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion and improving bond strength. Conversion coating involves applying a chemical treatment to create a thin layer of metal oxide or phosphate, which promotes adhesion between the adhesive and aluminum.

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Yes, 101 aluminum sheets can be used in the production of sporting goods. Aluminum is a lightweight and durable material that is commonly used in the manufacturing of various sporting equipment such as baseball bats, tennis rackets, and bicycle frames.

Send your message to us

Industrial Aluminum Sheets for Corrugated Aluminum Roofing Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords