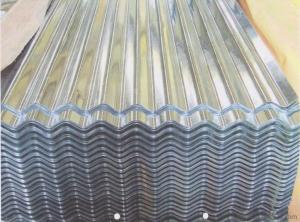

Aluminum sheet corrugated for any

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q:Are 101 aluminum sheets suitable for lightweight structural applications?

- Yes, 101 aluminum sheets are suitable for lightweight structural applications.

- Q:Can aluminum sheets be used for insulation jackets?

- Indeed, insulation jackets can indeed employ aluminum sheets. Aluminum possesses exceptional thermal conductivity characteristics, enabling it to proficiently deflect heat and hinder the transmission of thermal energy. Consequently, it becomes the perfect substance for insulation jackets, as it aids in preserving temperature regulation and reducing heat loss or gain. Furthermore, aluminum sheets are lightweight, long-lasting, and impervious to corrosion, rendering them a pragmatic option for insulation applications.

- Q:What are the different types of aluminum sheets available?

- There is a variety of aluminum sheets available, each with its own distinct properties and uses. Some of the most commonly used types are as follows: 1. Pure Aluminum Sheets: These sheets are composed entirely of aluminum and are known for their exceptional resistance to corrosion and high thermal conductivity. They are frequently employed in industries where lightweight and durability are crucial, such as aerospace. 2. Aluminum Alloy Sheets: These sheets are produced by combining aluminum with other elements like magnesium, copper, or zinc, in order to enhance specific properties. For instance, aluminum-magnesium alloy sheets (5000 series) possess remarkable strength and corrosion resistance, making them suitable for marine applications. 3. Painted Aluminum Sheets: These sheets are coated with paint or a protective layer, providing additional defense against corrosion and enhancing their visual appeal. They are commonly utilized in architectural projects and signage. 4. Perforated Aluminum Sheets: These sheets are characterized by evenly spaced small holes or perforations across their surface. They are frequently used in situations where airflow or visibility is required, such as HVAC systems, decorative panels, or speaker grilles. 5. Embossed Aluminum Sheets: These sheets feature a raised pattern or design on their surface, achieved through the process of embossing. This not only adds visual interest but also increases the sheet's strength, making it suitable for flooring, vehicle panels, or decorative purposes. 6. Anodized Aluminum Sheets: This type of aluminum sheet undergoes an electrolytic process known as anodizing, which creates a protective layer on the surface. Anodized sheets exhibit high resistance to corrosion and wear, making them ideal for outdoor applications like building facades, window frames, or automotive trim. Before selecting an aluminum sheet, it is crucial to consider the specific requirements of your project. Factors such as strength, corrosion resistance, appearance, and cost should be taken into account to ensure the most appropriate sheet is chosen for the job.

- Q:Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, aluminum sheets are suitable for manufacturing architectural column covers. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it ideal for exterior applications such as column covers. It can be easily shaped, bent, and fabricated to create custom designs and sizes, allowing for versatility in architectural projects. Additionally, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their aesthetic appeal and provide additional protection against weathering and wear. Overall, aluminum sheets provide a great combination of strength, versatility, and aesthetics, making them a suitable choice for manufacturing architectural column covers.

- Q:We made a thermos for school and we need to write a paper on it and the teacher wants to know what prevents whatI Used:Packing PeanutsAluminum foilPlastic ice cream pailA jar What it can prevent:RadiationConductionConvectionPlease Help! Thanks

- A wood stovepipe carries the fumes from the combustion of the wood into the chimney and outdoorsThe mating joint between each section of pipe is made to self-sealIn some cases that seal may not be tight enoughWhen this occurs, cold air will enter through the jointsThe cold air will prematurely condense the hot vapor into a solid called creosoteCreosote build up within the chimney causes air disturbances and inhibits the draw of the stoveCaulking the mating joints will increase the draw of the stove and reduce the build up of creosoteInstructions 1.Wear rubber gloves and old clothesThe high-temperature caulk is difficult to remove from hands and clothing due to its particular adhesive qualities2.Clean each mating surface of the wood stovepipe with the wire brushScrub the interior fitting male joint as well as the exterior mating female jointThe surface does not have to be a shiny metallic finish, but must be as clean as possible so the caulk will adhere to the metal.

- Q:so i have a mig welder with gas. i want to lear to weld aluminum, how does aluminum welding work? is there an attachment that i can use to weld aluminum with my welder? or do i need to buy a totally different welder? what do i need and everything...

- The main issue is that MIG welding aluminum REQUIRES the use of the high-current spray transfer mode. If you want to weld aluminum you need to have a MIG welder that provides AT LEAST 200 amps output. It would be preferable to have a 250 or 300 amp MIG machine, but 200 amps I would consider the absolute minimum. If your machine is less than 200 amps, you need a more powerful welder plain and simple You also need a teflon liner, hard plastic or teflon wire guides, and a pair of smooth double U groove rollers. Rollers used for steel wire are normally V groove design. This is unacceptable for aluminum because V-rollers create fine metal shavings which will clog the liner, tip and wire guides, resulting in jams. Aluminum wire is softer than steel and thus jams and wire bucking is a problem if you don't treat the machine with care. I recommend using 5056 aluminum wire. Also you should use a fairly short welding lead, no longer than 2 meters.

- Q:I have a 5052 aluminum sheet which is 10quot; by 5quot; by 1/16quot; (0.063quot;) thickWhat is the best method for curving it? I was thinking of clamping it to a piece of PVC pipe as a form, and hammering the plate into shape.

- Fat Ronnie's Fried Onion Rings 2 cupsFlour 1? tspSalt 1 tspGround Pepper ? tspBaking Powder 1 cup Buttermilk 1 Large Sweet Onion (sliced 1/2 wide) Vegetable Oil for Deep Frying Place buttermilk in one bowl and set asideMix flour, salt, pepper, and baking powder in separate bowlHeat oil at 375?F for fryingDredge onion rings in flour mixture first, then dip in butter milk and then coat with flour mixture againPlace onion rings in hot oil and do not crowd onion ringsWhen onion rings are golden brown remove from oil and drainMore salt may be added to your tasteThese were traditionally served in a brown paper bag from the Topeka, KS, location.

- Q:Other than the obvious.I mean like household objectsOne time I heard about using an apple.so now I just really want to knowAnd please don't say aluminum foil because those hits just hurt.lol

- potato, bottle, pen (make sure you take out the ink) and anything else you can make two holes and put a bowl on one hole and inhale through the other - my suggestion is get a bubbler or a bong

- Q:(1) For each of the following metals, how many electrons will the metal atoms lose when the metal reacts with a nonmetal: (a) Sodium: (b) Potassium: (c) Magnesium: (d) Barium: (e) Aluminum: (2) For each of the following nonmetals, how many electrons will the nonmetal atom gain when the nonmetal reacts with a metal: (a) Oxygen: (b) Fluorine: (c) Nitrogen: (d) Chlorine: (e) Sulfur: Please be niceI will give the best answer ten points within 24 hours!

- have him pass to the HRC homepageas quickly as he's there he will could pass to his branch e-newsletteron the perfect their could be a link that pronounces whats newclick on thisl ink and their would be yet another link that tells you the place the army desires human beings by utilising rank and MOS.

- Q:Are aluminum profiles suitable for automotive racks and carriers?

- Yes, aluminum profiles are suitable for automotive racks and carriers. Aluminum is a lightweight and strong material, making it ideal for applications where weight reduction is important, such as automotive racks and carriers. Aluminum profiles can be designed and engineered to meet specific requirements, allowing for customization and versatility. Additionally, aluminum is corrosion-resistant, ensuring the durability and longevity of automotive racks and carriers, even in harsh weather conditions. The material's high strength-to-weight ratio also contributes to improved fuel efficiency and reduced emissions. Overall, aluminum profiles provide a reliable and efficient solution for automotive racks and carriers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum sheet corrugated for any

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords