High Alumina Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks for Torpedo Car Iron Ladles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks in Torpedo Car Iron Ladles

Product name, Description, Raw material, Performance & Applications

ASC refractories, short for Alumina-Silicon Carbide-Carbon (Al2O3-SiC-C) refractories, represent a cutting-edge solution for the working lining of torpedo car and iron ladles in the steel industry.

These bricks are meticulously engineered using a premium blend of raw materials, including high-grade bauxite, fused alumina, silicon carbide, graphite, antioxidants, and various additives. Expertly shaped with a phenolic resin binder, they fall under the category of non-burnt carbon composite refractory materials. The production process strictly adheres to dimensional requirements and maintains a strong commitment to high-quality standards.

Our ASC refractories are purpose-designed to excel in the demanding environments of molten metal transportation. They exhibit exceptional attributes such as thermal stability, resistance to alkalis, slag, oxidation, and erosion.

These refractories are primarily used to line hot metal pre-treatment equipment, including torpedo-type mixed iron trucks and iron ladles, during the transfer of molten metal.By choosing our ASC refractory working lining bricks, steel manufacturers can significantly enhance the efficiency and reliability of their torpedo car iron ladles and other metallurgical molten iron pre-treatment equipment.

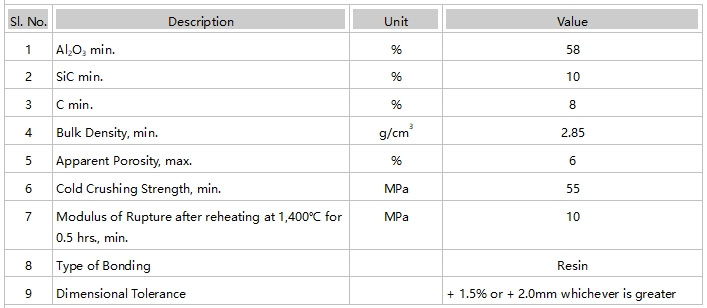

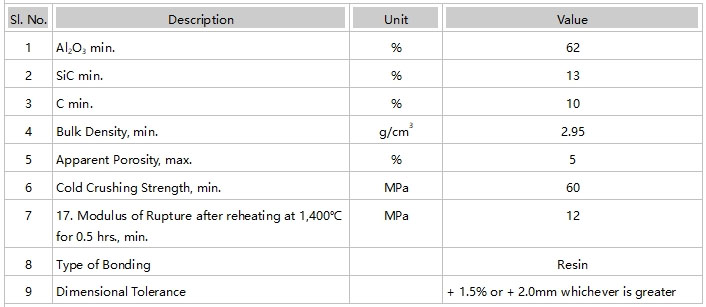

Chemistry and Physical Properties

The following tables present values for the content of Al2O3, SiC and C elements, bulk density, apparent porosity, cold crushing strength, modulus of rupture, type of bonding, and dimensional tolerance for both of the two types of ASC bricks: Standard and Three-removals.

Standard Type ASC Brick

Three-Removals Type Brick

- Three removals, referring to the removal of impurities such as phosphorus (P), sulfur (S), and silicon (Si) from the molten steel during the steel-making process. Three-Removals type bricks are specially designed to have a higher level of purity and lower impurity content than standard bricks.

Packaging

Here are some reference photos showcasing the packaging of our exporting ASC bricks. The ASC bricks are securely enclosed within robust MDF (Medium Density Fiberboard) wooden pallets or cases, with each package measuring approximately 110x100x75cm and weighing approximately 1 ton.

Contact Us

If you have specific requirements for ASC Working Lining, please inform us about the current usage of the product, existing brick types, and other information. We will adjust the content of materials based on your needs and priorities, enabling us to create a product that meets your requirements and budget. If you need us to design the brick shapes, please provide detailed torpedo tank drawings. ASC casting materials can also be produced and provided.

- Q: What is fireproof concrete?

- According to the different properties of fire resisting and heat resisting concrete, they can be divided into silicate, aluminate, phosphate, sulfate, chloride, sol and organic substance, fireproof and heat-resisting concrete, etc.. The following are mainly used silicate, aluminate, phosphate, sulfate fire, heat-resistant concrete.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- The difference between the two kinds of high alumina bricks is great. I perennial in Zhengzhou was responsible for the production and sale of colt refractories

- Q: Which is better, the soft core or the hard core?

- The use of each of the single core copper wire with low line, 1.5 square with cap line home, socket 2.5 square, air conditioning to walk alone line 4 square can, when the terminal box into a socket with leakage protection switch, prevent overload and short circuit.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Sulphide. A total of more than 200~300 kinds, followed by the type of silicate minerals, the weight of 0.25% of the crust. Chang Fu is an important nonferrous metal deposit, which is an important source of copper, lead, zinc, antimony and so on. It is of great economic value. The main features are: metal luster, color, streak is deep, low hardness, good thermal conductivity, than the major. Another feature is that because sulfides are often associated with magma, it is very easy to oxidize under the surface supergene action. Except for pyrite (6 ~ 6.5 hardness), the hardness is very low. Such minerals pyrite, chalcopyrite, galena, FeS2 CuFeS2, PbS, Sb2S3, stibnite sphalerite molybdenite, cinnabar HgS MoS2.

- Q: How to distinguish the good or bad of the high aluminum brick?

- Weigh the weight of the next block. According to the weight standard, a high alumina brick is 3.9 kg in weight, two in high alumina brick, three in high aluminium brick and 4.5 kg in 4.2. The same grade, the same type of high alumina brick, if the weight of a single brick to this standard, but for high quality high alumina brick, otherwise, can not reach such a weight, it shows good quality. If there is a crack, a large piece of broken angle, four sides of inequality, it is for substandard products.

- Q: What's the weight of the refractory bricks?

- According to shape and size can be divided into standard brick, ordinary brick, special brick, etc.. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What is the apparent porosity of high alumina brick?

- In the production of high alumina bricks in addition to the entity, there are many different sizes and shapes of different pores, pores can be divided into three categories: one side closed the other side and the outside world is called open pores, closed in the product not communicated with the outside is called closed pores, penetrating through pores called the few products.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The rotary kiln lining structure of rotary kiln and requirements on refractories calcining active lime according to the general output is divided into Nissan 300t, 400 t, 600 t, 800 t, 1000 t, 12000 t of kiln type, calcining zone temperature at 1350 degrees celsius. The kiln is divided into a discharge end, a cooling zone, a burning zone, a preheating zone and a feeding end, and the temperature of each section of the kiln ranges from 1000 DEG C to 1350 DEG C, and the requirements for refractory materials are different. The kiln refractory materials not only to withstand the high temperature impact, but also need to bear the material erosion, kiln rotation stress produced, so not only on the physico-chemical properties of refractory materials have strict requirements, but also for the construction of brick should be strictly.

- Q: What should be used as binder for making high alumina bricks?

- In addition, high alumina micro powder can be used as binding agent, or high alumina micro powder and clay powder are prepared according to a certain proportion, and synthetic mullite is used as bonding agent. With these binders, high alumina bricks without two expansion can be prepared.

Send your message to us

High Alumina Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks for Torpedo Car Iron Ladles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords