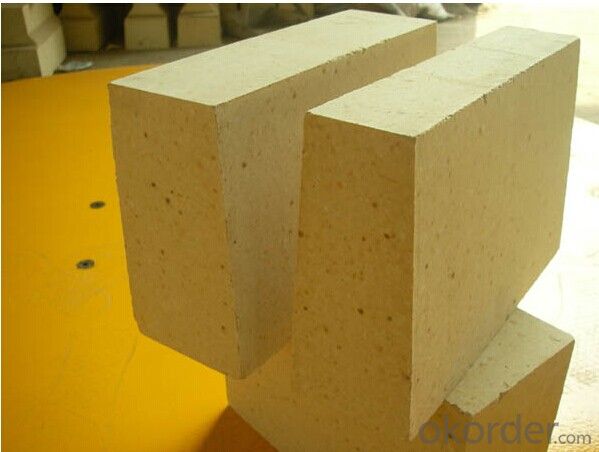

High Alumina Bricks for Anti-Spalling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

With excellent high temperature performance and spalling resistance,it is used for middle

temperature area of regenerator of glass tank.

Al2O3% ≥ | ZrO2% ≤ | A·P % ≤ | B·D g/cm3 ≥ | C·C·SMPa ≥ | 0.2MPaR·U·L℃ ≥ | T·S·R (1100℃ ≥ | ||

ANTI—SPALLING HIGH ALUMINA BRICKS | ||||||||

JJYRS-70 | 70 | 6-7 | 25 | 2.55 | 45 | 1470 | 20 | |

NEW TYPE ANTI—SPALLING HIGH ALUMINA BRICKS | ||||||||

JJYRS-76 | 76 | 25 | 2.5 | 55 | 1500 | 25 | ||

Specifications

refractory ladle lining brick

1) Good thermal shock resistance

2) High-temperature endurable

3) Good thermal insulation

Description:

1. Good acid stability

2. Good thermal performance

3. Good thermal shrinkage

4 Good resistance to abrasion and corrosion

Advantage:

Fire brick is refers to the Al2O3 content is 30% ~ 40% aluminum silicate.Clay brick is made of soft clay and 50% and 50% of hard clay grog, ingredients required by certain granularity, after forming, drying, burning under the high temperature of 1300 ~ 1400 ℃.Clay brick belongs to the weak acid refractory products, can resist acid slag and the erosion of acid gases, the alkali resistance ability is a bit poor. Clay brick has good thermal shrinkage.

- Q: What are the requirements for Rubble backfill height?

- Backfill should be filled with large stones, big face, small face upward, the decoration is stable, and then use small stones leveling, the gap between the stones can be swept into the slag, gravel, so that the gap filled.

- Q: Application characteristics of high alumina brick

- Load softening temperature. The softening temperature of high alumina brick products decreases with the increase of silica and alkali metal oxide content, but is higher than that of clay brick products, which is about 1420 - 1530 degrees centigrade. Al2O3. The softening temperature of corundum brick with content greater than 95% can reach above 1600 DEG C.

- Q: What materials are used for roof insulation?

- The other one is inorganic insulation materials, such as Portland, rare earth insulation, the thickness should be 5 cm or more, up to the high cost of auxiliary materials of construction, to reinforce, new inorganic insulation material, the material thickness, on the line of 2-3 cm, direct smear on the top of the house, without auxiliary material, than the price of wool, high aluminum silicate cotton.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: How much is one ton / ton of high alumina refractory brick?

- The price of high alumina refractory bricks is not equal, according to the quality index of GB2988-2012

- Q: The difference between ordinary and diatomite brick refractory brick

- Insulation products made from diatomaceous brick and porous diatomite. The main raw material is natural porous diatomite, and then a small amount of clay and fuel are added. The volume density of diatomite brick was 0.7g/cm3, compressive strength at room temperature is 1 ~ 2MPa, the coefficient of thermal conductivity at 400 C for 0.13 ~ 0.20W/ (M - K), the apparent porosity is greater than 70%, the coefficient of thermal expansion (1280 degrees) 0.9 x 10 - 6 DEG -1, refractoriness is greater than 1250 DEG C. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius. Mainly used in industrial kilns and other thermal equipment, thermal pipes insulation materials, generally withstand the hot surface temperature of about 1000 degrees celsius.

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.Thermal shock stability is much better than clay brick.

- Q: What is the difference between metal compounds and metal solid solutions?

- Solid solution refers to the alloy phase in which the solute atoms are dissolved into the solvent lattice and remain solvent type. A crystalline substance consisting usually of atoms or molecules in which a chemical substance is dissolved as a base; other substances are found in alloys and silicate systems; also present in polyatomic substances. The mixture can be treated as a solution when the crystal structure of the solvent can be stabilized and homogeneous after addition of solute. Some mixtures can form solid solutions in many concentrations, while some mixtures do not form solid solutions at all.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Because the hot air outlet of the top burning hot blast furnace is high, the installation requirement of the hot air manifold is high, and the requirement of the strength of the pillar structure is higher, so the rectangular arrangement of the hot blast stove is arranged. The top burning hot blast stove is located on the furnace top because of burner and hot air valve,Therefore, operation, maintenance and installation all require mechanization and automation. Also, because these water cooled valves are mounted with a high elevation,Therefore, the demand for cooling water supply pressure should be improved accordingly, the use of large top burning hot blast stove, the key lies in the design of high-power high-efficiency short flame burner. The top combustion hot blast furnace absorbs the advantages of internal combustion and external combustion hot blast stoves, and overcomes some of their shortcomings,Its structure can meet the requirements of modern blast furnace for high temperature, high pressure and large scale development,Combustion capacity, while meeting production requirements, has been successfully reduced by many devices,

Send your message to us

High Alumina Bricks for Anti-Spalling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords