High Alumina Brick for Blast Furnace High Refractoriness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory Brick for Blast Furnace High Refractoriness

Brief discription for Refractory Brick for Blast Furnace

CMAX high alumina refractory bricks are classified according to alumina content ranging from 48% to 90%.

CMAX refractory brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Refractory Brick for Blast Furnace

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for Refractory Brick for Blast Furnace

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

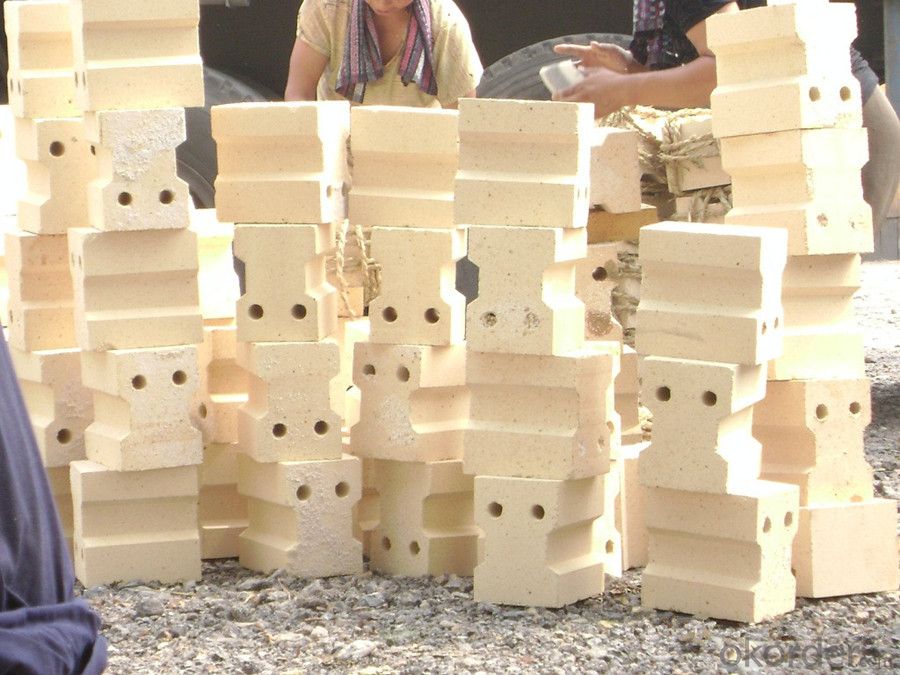

Images/photographs for Refractory Brick for Blast Furnace

◆ breif images-different shape for different usage

◆ Packaging for Refractory Brick for Blast Furnace

◆ Producing Equipment for Refractory Brick for Blast Furnace

◆ Testing Mashines for Refractory Brick for Blast Furnace

WHO WE ARE?

CNBM International (China National Building Materials Group Corporation) 500 Fortune Company.

we are the main supplier for

ALLIED MINERAL PRODUCTS, INC

REFRACTORIES INCORPORATED

SRS SORG REFRACTORY SYSTEMS GMBH,

SUNWARD REFRACTORIES CO., LTD

LILAMA69-1 JOINT STOCK COMPANY etc.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What is the heat preservation material used in a laboratory furnace?

- Thermal insulation cotton is a high-purity clay clinker, alumina powder, silica powder, chromium sand and other raw materials in the industrial furnace melting at high temperature, forming fluid. Then, compressed air is used to blow or use the wire throwing machine to turn the yarn into a fiber shape. After the cotton collector is collected, the cotton is formed into a heat preservation cotton.The high alumina brick is usually made of high alumina clinker with small amount of clay. After grinding, the high alumina brick is poured and shaped in the form of slurry by the way of gas generation or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- In the meantime, the free silica content of silicon brick is as high as 90% above. Therefore, the most serious damage is silicon brick, followed by clay brick, high alumina brick, magnesia brick and so on.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Sulphide. A total of more than 200~300 kinds, followed by the type of silicate minerals, the weight of 0.25% of the crust. Chang Fu is an important nonferrous metal deposit, which is an important source of copper, lead, zinc, antimony and so on. It is of great economic value. The main features are: metal luster, color, streak is deep, low hardness, good thermal conductivity, than the major. Another feature is that because sulfides are often associated with magma, it is very easy to oxidize under the surface supergene action. Except for pyrite (6 ~ 6.5 hardness), the hardness is very low. Such minerals pyrite, chalcopyrite, galena, FeS2 CuFeS2, PbS, Sb2S3, stibnite sphalerite molybdenite, cinnabar HgS MoS2.

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Fire resistance is an important performance index of refractory materials, but it does not represent the highest temperature in actual use of refractory materials. In actual use, refractories also bear certain pressure, therefore, must consider the high strength at high temperature refractory material, which is in high temperature under certain pressure without deformation, such as the NZ-40 refractory refractory degree up to 1730 DEG C, but the maximum temperature is only 1350 degrees celsius.

- Q: The difference between light high alumina brick and heavy aluminum brick

- High aluminum brick is one of the ideal heat insulating material, with high strength, low thermal conductivity, good insulation performance, low price and other characteristics, has been widely used in ceramic tunnel kiln, roller kiln, shuttle kiln, kiln wall, it is also used in various heating furnace coking furnace of iron and steel industry and other thermal equipment heat treatment, lining material, and has broad market prospects.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- High R.U.L, low creep high alumina brick [1] is using high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: What is the difference between metal compounds and metal solid solutions?

- Solid solution refers to the alloy phase in which the solute atoms are dissolved into the solvent lattice and remain solvent type. A crystalline substance consisting usually of atoms or molecules in which a chemical substance is dissolved as a base; other substances are found in alloys and silicate systems; also present in polyatomic substances. The mixture can be treated as a solution when the crystal structure of the solvent can be stabilized and homogeneous after addition of solute. Some mixtures can form solid solutions in many concentrations, while some mixtures do not form solid solutions at all.

Send your message to us

High Alumina Brick for Blast Furnace High Refractoriness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords