Aluminum Bronze Sheets for DC Aluminium Car Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of DC Aluminium sheet for making car trailer

CC Aluminium sheet for making trailer is one semi-finished aluminium material. This sheet can be cut to size you wanted in production. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of DC Aluminium sheet for making car trailer

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of DC Aluminium sheet for making car trailer

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of DC Aluminium sheet for making car trailer

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of DC Aluminium sheet for making car trailer

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

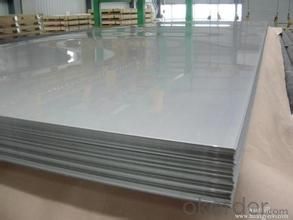

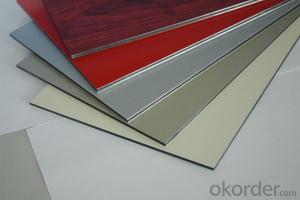

6. Image of DC Aluminium sheet for making car trailer

7. Package and shipping of DC Aluminium sheet for making car trailer

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors. Aluminum is a highly conductive metal, which makes it an excellent choice for transferring electric current. It has a low electrical resistance, allowing for efficient transmission of electricity. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular material for electrical connectors in various industries such as automotive, aerospace, and electronics. However, it is important to note that aluminum connectors may require additional measures to prevent galvanic corrosion when used with dissimilar metals.

- Q: What are the specific rules or codes that govern the use of aluminum sheets in residential construction?

- <p>Yes, there are special regulations related to using aluminum sheets in residential buildings. These regulations can vary by country, state, or municipality, but generally, they cover aspects such as material standards, fire resistance, structural integrity, and energy efficiency. For example, aluminum sheets must meet specific thickness and strength requirements to ensure structural safety. They must also comply with fire codes, which may require certain fire-resistant coatings or treatments. Additionally, energy codes may dictate the insulation value of aluminum sheets used in walls or roofs to improve thermal performance. It's crucial to consult local building codes and regulations to ensure compliance when using aluminum sheets in residential construction.</p>

- Q: What is the typical price range for aluminum sheets?

- The price of aluminum sheets can differ based on several factors, including thickness, grade, size, and quantity required. Typically, aluminum sheets can be priced anywhere between $0.50 and $5 per square foot. Thinner sheets or lower-grade aluminum are generally found at the lower end of the price spectrum, whereas thicker sheets or higher-grade aluminum tend to be on the higher end. It's worth mentioning that market conditions, location, and supplier can also impact prices. Therefore, it is recommended to consult specific suppliers or conduct market research for the most precise and current pricing details.

- Q: The real bumper/ reinforcement bar that is behind the plastic bumpers. Magnet don't stick to it and it don't rust which both types of metal are pretty much like that.

- Aluminum, stainless is too expensive and not ductile enough to be made into bumpers, especially of that complexity. As far as the magnetism, the magnet would only stick to low nickel stainless and its not likely that they would use 308 on a consumer vehicle.

- Q: An aluminum clock pendulum having a period of 1.00 s keeps perfect time at 20 degrees celcius. (A) When placed in a room at a temperature of -5.0 Celcius, will it gain or lose time? (B)How much time will it gain or lose every hour.

- A for a swinging pendulum period T =2pi*√(L/g), where L is length of the pendulum, g=9.8m/s^2; metals shrink when cooled, so period will decrease, number of ticks per hour will increase, the clock will hurry up; B? period at t1°=20C° is T1=2pi*√(L1/g); ? period at t2°=-5C° is T2=2pi*√(L2/g); ? the law of linear extension says L2/L1= 1+s*Δt°, where s=23.1·10-6 (1/К°) is specific linear extension of aluminum, Δt°=t2°-t1°; ? thus T2/T1 =√(L2/L1) = √(1+s*Δt°) =f1/f2, where frequency f1= 1 Hz at 20C° or 3600 ticks per hour, hence frequency at -5C° is f2= f1/√(1+s*Δt°); therefore instead of 3600 ticks per hour the clock will do 3600/√(1+s*Δt°) ticks per hour; thus it will gain 3600*(1/√(1+s*Δt°) –1) = = 3600*(1/√(1 -23.1·10-6 *25°) –1) = 1.04 s/hour;

- Q: you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets can vary depending on the manufacturer and specific application. However, in general, the standard maximum sheet size for aluminum sheets is typically 4 feet by 12 feet (48 inches by 144 inches). This size is commonly used in various industries such as construction, automotive, and aerospace. It is important to note that larger sizes may be available upon request from certain suppliers, but these may come with additional costs and considerations.

- Q: Are aluminum sheets resistant to UV rays?

- Yes, aluminum sheets are generally resistant to UV rays.

- Q: Need to polish some small aluminum tubing, preferably to chrome like shine. What tools do I need? Thinking about buying 6 bench grinder, buffing? wheels and polish compound... Does it sound about right?

- Aluminum oxidizes almost instantly, so it is never going to keep a good shine. You can send it to a plating shop and they will anodize it, which means a permanent oxidized layer and that may or may not retain some shine but at least it won't ever change much. (But it is easily stained.) Consider plating some other metal on the surface. You will need advice from a plating shop about that. Maybe you could use chrome plated water pipe? That would be cheaper than a custom job.

- Q: Can aluminum sheet be used for architectural façade systems?

- Indeed, architectural façade systems can make use of aluminum sheet. The lightweight, durable, and corrosion-resistant properties of aluminum make it a favored option for building exteriors. It can be easily manipulated and fabricated into a plethora of shapes and sizes, thus rendering it suitable for the creation of intricate designs and architectural elements. Moreover, aluminum can be coated or treated in various ways to enhance its appearance and shield it from weathering. The versatility, aesthetic appeal, and long-term cost-effectiveness of aluminum sheet make it an exceptional selection for architectural façade systems.

Send your message to us

Aluminum Bronze Sheets for DC Aluminium Car Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords