Aluminum Cladding Sheets - Aluminium Checkered Plate for Auto Trailers Supply from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

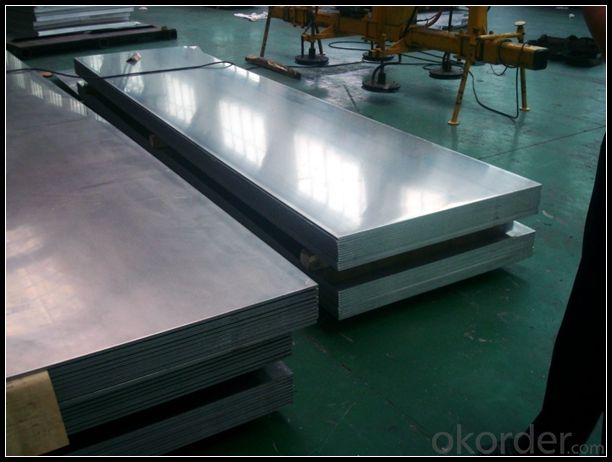

5. Image of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

6. Package and shipping of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be custom cut to specific dimensions?

- Certainly! Custom cutting aluminum sheets to specific dimensions is absolutely possible. Aluminum is a highly versatile material that lends itself easily to cutting and shaping using a wide array of tools and techniques. This remarkable adaptability enables precise customization to fulfill specific requirements and measurements. Whether for industrial, commercial, or residential purposes, aluminum sheets can be expertly cut to desired sizes, guaranteeing a flawless fit and optimal functionality. Furthermore, the ability to custom cut aluminum sheets allows for unparalleled design flexibility, resulting in the creation of distinctive and tailor-made solutions.

- Q: what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- the difference between iron, steel aluminium is that aluminium contains no carbon as iron steel do. Iron steel over time will rust but aluminium wont. In taking out carbon out off iron to make steel is it needs the carbon % to be less than 0.5% as with iron it still contains carbon at 1.5% to 2% so is not a very strong metal and steel. In Strength Steel is stronger than aluminium and also weights heavier than aluminium. Aluminium do sent corrode because it do sent contain iron as with steel it dose as oxygen reacts with it over time causing it to rust. This is why a coat of red oxide paint is put on it for finishing purposes. In cost efficient steel is the cheaper as steel is a faster process in making it. As you only need 3 ingredients which are Iron ore, Coke which is coal burnt to take off impurities and leaves carbon. As with Aluminium it is more expensive as an expensive process to make and the ore and can only be mined in sear-tonn countries such as Australia. Hope this Helps :o)

- Q: Can aluminum sheet be used for electrical grounding applications?

- Indeed, aluminum sheet finds utility in electrical grounding applications. It possesses remarkable conductive properties, rendering it apt for employment in grounding systems. Its low resistance and exceptional electrical conductivity make it a common choice in diverse electrical applications. With the capability to proficiently transport electrical current and securely disperse it into the ground, aluminum sheet guarantees the safeguarding of electrical systems and averts potential electrical dangers. Moreover, the lightweight and corrosion-resistant attributes of aluminum establish it as a favored option for grounding applications across numerous industries, encompassing construction, automotive, and aerospace.

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- Since aluminum only has 3 valence electrons it will be missing two electrons from its octet. This means that one of the chloride groups must share an extra electron group with the aluminum. Any three of the chlorides can share an extra electron pair with it (i.e. they'll have 2 lines attached to aluminum), so there is resonance. There are 3 to be specific, one for each chloride sharing another electron pair with Al.

- Q: What are the different forming methods for aluminum sheets?

- Aluminum sheets can be shaped using various forming methods. These methods encompass: 1. Roll Forming: By passing the aluminum sheets through a series of rollers, they gradually take on the desired form. Roll forming is commonly employed to produce elongated shapes like channels or rails. 2. Press Forming: This technique involves utilizing hydraulic or mechanical presses to exert force on the aluminum sheet, resulting in the desired shape. Press forming is often favored for creating intricate shapes with precise tolerances. 3. Stretch Forming: The aluminum sheet is clamped at its edges and then stretched over a die, causing it to conform to the die's shape. Stretch forming is frequently utilized to manufacture curved or contoured parts. 4. Deep Drawing: This method entails inserting an aluminum sheet blank into a die and using a punch to force the material into the die cavity, creating a hollow shape. Deep drawing is commonly employed for producing cylindrical or box-shaped parts. 5. Hydroforming: Hydraulic pressure is employed to shape the aluminum sheet against a die. Hydroforming is particularly advantageous for crafting complex shapes with smooth surfaces. 6. Incremental Sheet Forming: This technique involves a CNC machine moving a small tool over the aluminum sheet's surface, gradually shaping it by applying localized pressure. Incremental sheet forming is often employed for prototyping or small-scale production. These forming methods offer distinct advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and production volume.

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- Aluminium foil is manufactured to be of 'food grade' (i.e. safe to be used around food). It heats and insulates. It would never react with the food contained on/in it. Unless you're boiling your tomatoes in Sulphuric Acid of course! :-P

- Q: Is it possible to construct furniture using aluminum sheets?

- <p>Yes, you can use aluminum sheets to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material that is often used in modern furniture design. It can be easily shaped and welded, making it suitable for a variety of furniture pieces such as tables, chairs, and shelving. However, it's important to consider the design and structural integrity, as well as the finish and comfort, when creating furniture with aluminum. It's also advisable to use appropriate tools and techniques to ensure safety and quality in the construction process.</p>

- Q: Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- Safely Permanently Remove Moles, Warts and Skin Blemishes

- Q: Which kind of glue can bond two pieces of aluminum sheets?

- You can use AB glue.

- Q: What are the different types of patterns available for textured aluminum sheets?

- There are various types of patterns available for textured aluminum sheets, including stucco, diamond, pebble, hammered, and brick patterns. These patterns are created through embossing or rolling processes, providing different textures and visual effects for decorative or functional purposes.

Send your message to us

Aluminum Cladding Sheets - Aluminium Checkered Plate for Auto Trailers Supply from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords