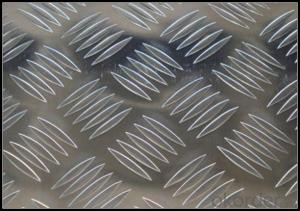

Aluminum Truck Deck Plate

Aluminum Truck Deck Plate Related Searches

Aluminum Deck Plate Semi Truck Aluminum Deck Plate Aluminum Diamond Deck Plate Aluminum Dock Plate Aluminum Deck Plate Products Aluminum Cover Plate Aluminum Ramp Plate Dock Plate Aluminum Aluminum Wall Plate Aluminum Diamond Plate Truck Box Aluminum Tool Plate Aluminum Floor Plate Aluminum Charger Plate Aluminum Traction Plate Aluminum Motor Plate Aluminum Backing Plate Aluminum Ramp Top Plate Aluminum Paper Plate Aluminum Tooling Plate Aluminum Mounting Plate Aluminum Grill Plate Aluminum Metal Plate Tractor Supply Aluminum Plate Aluminum Surface Plate Aluminum Dock Plate For Sale Aluminum Push Plate Aircraft Aluminum Plate Aluminum Pressure Plate Aluminum Heel Plate Aluminum Base PlateAluminum Truck Deck Plate Supplier & Manufacturer from China

Aluminum Truck Deck Plate is a type of durable and lightweight flooring solution designed specifically for use in commercial vehicles such as trucks. Made from high-quality aluminum, these plates offer a strong and corrosion-resistant alternative to traditional steel flooring options. The product is known for its ability to withstand heavy loads and provide a slip-resistant surface, making it ideal for various transportation needs.Aluminum Truck Deck Plate is widely used in a variety of applications, including cargo transportation, logistics, and construction industries. Its versatility allows it to be utilized in different scenarios, such as securing cargo, protecting the truck bed from damage, and providing a stable platform for workers to stand on during loading and unloading processes. The lightweight nature of the aluminum material also contributes to fuel efficiency and reduced emissions, making it an environmentally friendly choice for many businesses.

Okorder.com is a leading wholesale supplier of Aluminum Truck Deck Plate, boasting a large inventory that caters to the diverse needs of customers across various industries. By offering a comprehensive range of sizes, thicknesses, and designs, Okorder.com ensures that clients can find the perfect Aluminum Truck Deck Plate solution for their specific requirements. With competitive prices and reliable service, Okorder.com has established itself as a trusted source for high-quality aluminum truck deck plates in the global market.

Hot Products