1050 1060 1070 3003 CC/DC Aluminum circles are used to make cookware/lighting/traffic signs

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum circles, as the name suggests, are aluminum materials with a circular shape. It is mainly made of aluminum alloy. They are usually made by stamping or cutting aluminum plates and have good conductivity, corrosion resistance and machinability. Common alloy series include 1 series, 3 series, 5 series, 6 series and 8 series, among which 1 series (such as 1060, 1070), 3 series (such as 3003), 5 series (such as 5052, 5083) and 6 series (such as 6061, 6063) are the most common.

CC/DC aluminum circle specifications:

| Alloy | 1060, 1050, 1070, 1100, 3003, 5052, etc. |

| Temper | O/Ho, H12, H14, H18, H24, hard, soft, stretching |

| Process | cold rolling or hot rolling |

| Thickness | 0.2-160 mm |

| Diameter | 100-1250 mm (diameter tolerance: +/-2 mm) |

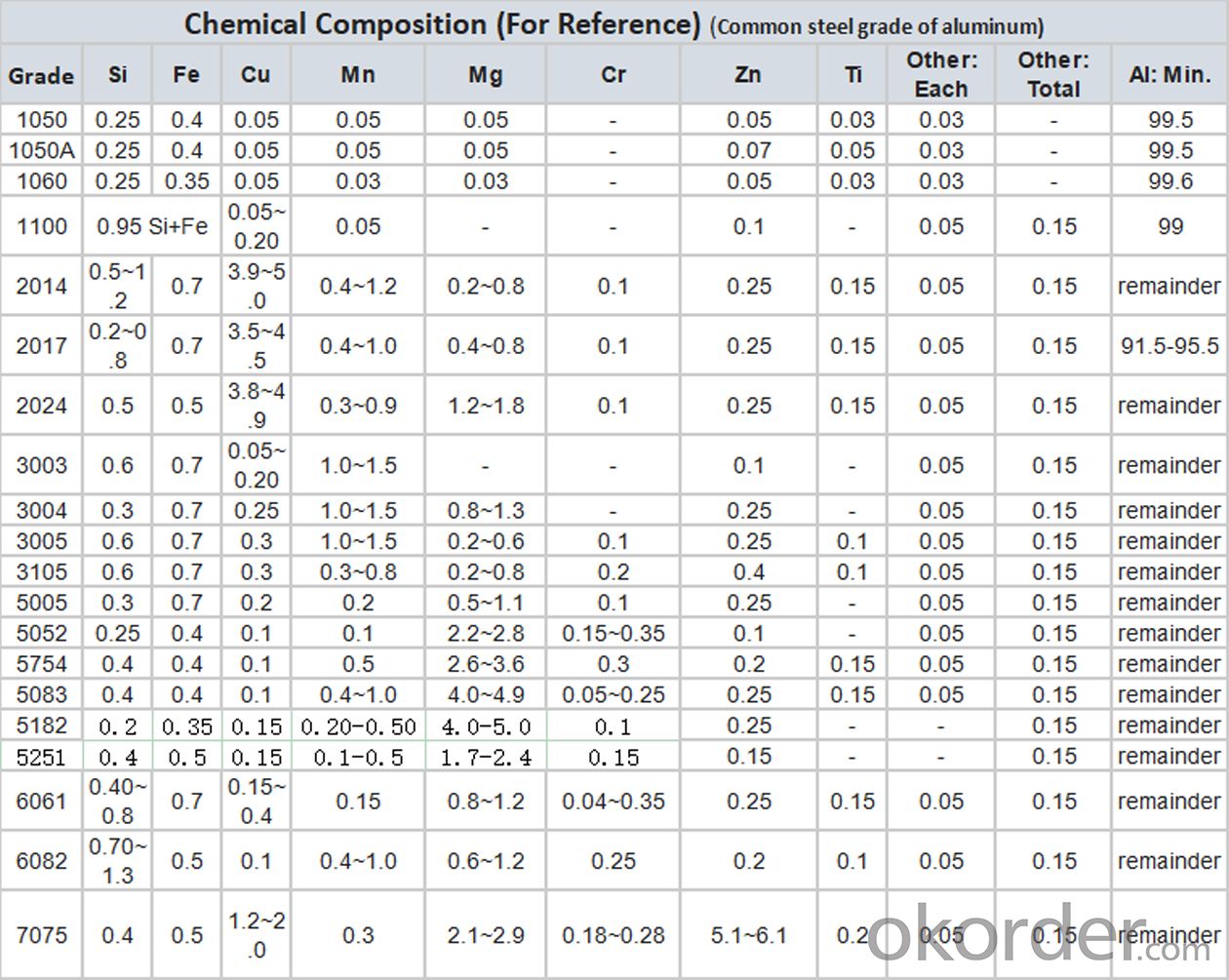

Chemical composition:

Application areas of aluminum disc:

Aluminum circles have a wide range of applications, mainly including electronics, daily chemicals, medicine, culture and education, and auto parts. Aluminum disc also play an important role in electrical appliances, insulation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other fields. For example, in kitchenware, aluminum circles are used in the manufacturing process of products such as non-stick pans and pressure cookers; in hardware products, aluminum discs are also used in the production of products such as lampshades, water heater shells, and stretch tanks.

Aluminum Plates and Rounds Depending on the usage, aluminum rounds with different thickness, diameter and alloy composition can be selected to meet specific needs.

FAQ:

Q1: Where is your factory located?

A1: Our factory is in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Equipped with various machines, such as aluminum plate machine, aluminum round machine, embossed aluminum coil machine, aluminum roof sheet machine, kraft paper/polysurlyn/pvc film coated aluminum coil machine, aluminum foil machine, etc.

Q2: What are the main products of your company?

A2: Our main products are aluminum plates/sheets, aluminum foil, aluminum coil, aluminum round/circle, aluminum roof sheet, aluminum coil with blue pvc film, embossed aluminum plates/sheets, color coated aluminum coil/sheets, aluminum tubes, aluminum wires, aluminum rods, PS/CTP sheets, etc.

Q3: How do you control quality?

A3: Factory test certification is provided with the goods, and third-party inspection can be provided.

Q4: How can I get your quotation?

A4: Please mention alloy and state, application, thickness, tensile strength, elongation, etc., we will quote as soon as possible.

Q5: How about the delivery time?

A5: Usually about 7-35 days, depending on different order requirements.

Q6. Can you provide samples?

A6: Yes, small samples are free, freight collect.

Customized samples take about 5-7 days.

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: Can 101 aluminum sheets be used in the production of musical instruments?

- Yes, 101 aluminum sheets can be used in the production of musical instruments. They offer good conductivity and durability, making them suitable for various components like instrument bodies, panels, or parts that require lightweight construction.

- Q: How do aluminum sheets perform in terms of fire resistance?

- Aluminum sheets possess outstanding fire resistance characteristics. This material, aluminum, is non-combustible, meaning it does not burn or contribute to the propagation of fire. In fact, aluminum has a remarkably high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), rendering it highly resistant to heat. When subjected to fire, aluminum generates a thin layer of oxide on its surface, creating a protective barrier that hinders further oxidation. This oxide layer is highly stable and effectively prevents the material from igniting or emitting flammable gases. Moreover, aluminum sheets exhibit low thermal conductivity, which reduces the ease with which they transfer heat compared to other metals. This property further enhances their fire resistance. These fire-resistant attributes position aluminum sheets as a preferred choice in a wide range of applications where fire safety is a primary concern, including building construction, aerospace industry, automotive manufacturing, and electrical enclosures. Aluminum sheets are commonly utilized in exterior cladding, roofing, and insulation systems, providing an additional layer of safeguard against fire hazards. It is essential to acknowledge that while aluminum sheets themselves possess high fire resistance, the overall fire performance of a structure or system relies on factors such as design, installation, and the use of other materials in conjunction with aluminum sheets. Therefore, it is vital to adhere to appropriate fire safety regulations and guidelines to ensure optimal fire resistance in any given application.

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. They are lightweight, durable, and resistant to corrosion, making them an excellent choice for roofing materials. Additionally, aluminum sheets have good thermal properties, reflecting sunlight and helping to keep the building cool.

- Q: What are the different methods of surface etching for aluminum sheets?

- There are several methods of surface etching for aluminum sheets, including chemical etching, laser etching, and mechanical etching. Chemical etching involves applying an etchant solution to the surface of the aluminum sheet, which selectively removes material to create the desired pattern or design. Laser etching uses a high-energy laser beam to vaporize or ablate the surface of the aluminum, creating precise and detailed patterns. Mechanical etching involves using physical tools or abrasive materials to physically remove material from the surface, typically resulting in a more textured or roughened finish.

- Q: what family does aluminum belong to?its NOT the boron or aluminum family.i know its group 13. i need the family name.please help

- Aluminum is an orphan metal- (orphans appear in groups 3, 4, and 5 of the periodic table). They are called orphans simply because none belongs to a clearly defined family (like alkaline earth, transition metals, halogens, etc). Sometimes aluminum and the three elements below it in Group 3—gallium, indium, and thallium—are lumped together as the aluminum family, but that's not a clearly recognized family.

- Q: i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- This Site Might Help You. RE: can i join copper to aluminum? i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- Q: Is it possible to apply paint to an aluminum sheet roof after it has been installed?

- <p>Yes, you can paint your aluminum sheet roof after installation. However, it's crucial to ensure the surface is clean and free of any contaminants. Use a primer specifically designed for aluminum to enhance adhesion and durability. Apply a high-quality paint suitable for metal surfaces, following the manufacturer's instructions carefully. This process can help protect the roof from weathering and enhance its appearance, but it's recommended to consult with a professional to ensure the best results and longevity of the paint job.</p>

- Q: Can 101 aluminum sheets be polished to a mirror-like finish?

- A mirror-like finish can be achieved on 101 aluminum sheets. Aluminum, being a lightweight and highly malleable metal, can be easily polished to obtain a reflective surface. Nevertheless, achieving a mirror-like finish on aluminum requires several steps and the use of appropriate polishing techniques and materials. To achieve a mirror-like finish on aluminum sheets, it is customary to begin by thoroughly cleaning the surface to eliminate any dirt, debris, or oxidation. Following that, sanding the surface with progressively finer sandpaper grits is necessary to eliminate imperfections or scratches. This step is vital in order to create a smooth and uniform surface that can be polished to a high level of shine. Once the sanding is completed, the polishing stage comes into play. There are various methods and materials available for polishing aluminum, such as abrasive compounds, buffing wheels, and polishing pads. These tools are utilized to exert pressure and friction on the aluminum surface, effectively removing any remaining scratches or imperfections and resulting in a smooth, reflective finish. Ultimately, to achieve a genuine mirror-like finish, the process of buffing or burnishing is often employed. This entails applying a polishing compound to the aluminum surface using a soft cloth or a specialized buffing wheel. The compound further refines the surface and enhances its reflective properties, ultimately leading to a mirror-like finish. It is important to note that achieving a mirror-like finish on aluminum can be a time-consuming and labor-intensive process, particularly when dealing with a large quantity of sheets like 101. Additionally, the quality of the aluminum sheets themselves and the skill level of the individual performing the polishing can also impact the final outcome. Nevertheless, with the right materials, techniques, and patience, it is indeed possible to polish 101 aluminum sheets to a mirror-like finish.

- Q: what's the difference between aluminum sheet detergent and central air-condition detergent?

- Central air condition cleaning includes air-cooled condenser cleaning and water-cooling condenser cleaning, if it’s air-cooled condenser cleaning, you can use aluminum sheet detergent.

Send your message to us

1050 1060 1070 3003 CC/DC Aluminum circles are used to make cookware/lighting/traffic signs

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords