High-Quality Aluminum Sheets for Cargo Trailers - China Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dear Sir/Madam,

This is Hannah XU, the Sales Manager of Aluminum Dept., from CNBM (China National Building Material) International Corporation, which is a subsidiary company and an export platform of CNBM Group. CNBM Group is the second largest building materials company in the world, reputable for having 300 subsidiary factories and branch companies in six countries, including U.S.A., U.A.E., Russia.

I found your company from Internet and wonder whether your company needs any aluminum products at present. We are able to supply 1,2,3,5,6,8 series alloy coil, foil ,circles,and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011.

We have been supplying Alu. Products for the global customers for more than 25 years and 6-sigma Quality Management System guaranteed. I assure you that our product can meet all your needs and be fully annealed.

If there is any inquiry, please let me know and then I will offer you our best prices. For detailed information about us, please visit our website at: www.icnbm.com or www.okorder.com Looking forward to your kind reply!

Yours Sincerely,

- Q: I'm 17 and it has been very hard finding a deodorant that makes me stop sweating. I told my dad I wanted to get Ban or Mitchum cause the percentage of Aluminum is very high. He said the Aluminum in deodorant has links to alzheimers, is that true? Also my sister said I could just scrub with soap morning and night, use regular deodorant without antipersperant and that would make me stop sweating too. But since i'm a teenager and my hormones are still weird would that be strong enough to stop sweat?

- aluminum oxide in antipersperant does lead to alzheimer's, yes. but antiperspirant is not deodorant, and deodorant does not contain aluminum. sweating is a natural bodily function. if you need to sweat, sweat. it's odor that should bother people.

- Q: Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q: How do aluminum sheets perform in terms of sound insulation?

- Aluminum sheets are not well-known for their sound insulation properties. Due to their relatively low density and thinness, aluminum sheets do not provide substantial soundproofing capabilities. They are more commonly used in applications where their lightweight nature, corrosion resistance, and thermal conductivity are desired, rather than for their sound insulation properties. For effective sound insulation, other materials such as rubber, foam, or fiberglass are often preferred.

- Q: i heard that aluminum causes Alzheimers and i was wondering if there is any aluminum in tin.

- No Aluminium (Al) is an element with atomic number 13. Tin (Sn) is another element with atomic number 50

- Q: is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

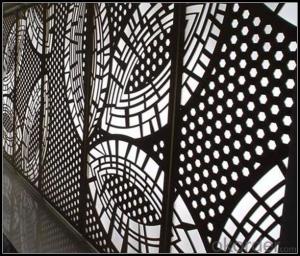

- Q: Explain the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with several options to enhance their appearance, durability, and functionality. These include: 1) Anodizing, which creates a protective oxide layer, 2) Powder coating, offering a wide range of colors and textures, 3) Liquid painting, for a smooth, painted finish, 4) Laminating, which bonds a protective film to the surface, 5) Electrolytic coloring, resulting in a variety of colors, 6) PVD (Physical Vapor Deposition), for a high-quality, durable finish, and 7) Thermal spraying, applying a coating to improve wear resistance. Each method serves different purposes and has its advantages and limitations.</p>

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: The question asks if it is possible to recycle used aluminum foil to create new aluminum sheets.

- <p>Yes, recycled aluminum foil can be used to make new aluminum sheets. The process involves collecting and sorting the foil, which is then cleaned and melted down. The molten aluminum is poured into molds or rolled into sheets, creating new aluminum products. This recycling method is not only environmentally friendly but also economically viable as it saves energy compared to producing aluminum from raw materials.</p>

- Q: What is the thickness range of aluminum sheets?

- The thickness range of aluminum sheets can vary depending on the specific application and industry standards. However, commonly available aluminum sheets typically range in thickness from 0.006 inches (0.15mm) to 0.25 inches (6.35mm). For more specialized applications, thicker aluminum sheets may be available. It is important to note that different alloys and grades of aluminum may have different thickness ranges, so it is essential to consult the specific requirements and standards of the intended use case.

- Q: What does aluminum plate "3003-H24" mean?

- According to the main alloy aluminum alloy elements can be divided into 2 * * * for Al Cu alloy aluminum (Al--Cu), 3 * * * aluminum manganese alloy aluminum (Al--Mn), 4 * * * series of aluminum silicon alloy aluminum (Al--Si), 5 * * * for aluminium magnesium alloy aluminum (Al--Mg). 6 * * * for Al Mg Si alloy aluminum (AL--Mg--Si), 7 * * * for aluminum and zinc alloy aluminum [AL--Zn--Mg-- (Cu)].Aluminum status: 1, F: free machining status. 2 and O: annealed condition 3 and H: work hardening state. 4, W: solid solution heat treatment state. 5, T: heat treatment state.

Send your message to us

High-Quality Aluminum Sheets for Cargo Trailers - China Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords