Aluminum Camper Sheets for Corrugated Silo Structures

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

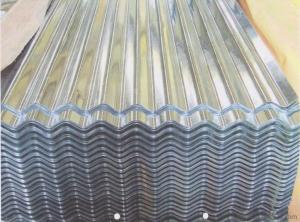

Corrugated Aluminum Sheet for Silo Structure

Description of Corrugated Aluminum Sheet for Silo Structure

Product | PPGI coils/Steel |

Base material | galvanized steel |

Thickness | 0.14mm-0.60mm |

Width | 665mm-1050mm |

Coil Weight | 4-6tons |

Standard | SGCC,DX51D,A653,SGCH |

Color | All RAL colors(standard international color)or customers samples’ color |

Zinc-coating | 40-160 g/m2 |

Coil ID | 508mm~610mm |

Technique | Cold rolled- galvanized—color coated |

Painting | Top painting:5~20μm Back painting: 5~7μm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Feature | Prepainted Steel Coils have excellent performance of decoration, corrosion resistance etc. |

Shipment time | within 10-15workdays |

Export package | waterproof paper, galvanized steel covered and steel strip packed |

Payment | T/T, L/C at sight |

Main Features of Corrugated Aluminum Sheet for Silo Structure :

Standard:JIS G3302 / JIS G3312 / ASTM A653M / A924M 1998/ GBT12754-2006,GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93

Technique:hot rolled/cold rolled,pre-painted, hot rolled/cold rolled

FAQ:

Q:Why should you choose us?

A: Chose happens because of quality, then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train

Quick goods delivery, our factories locate near the seaport, which is very convenient for transportation.

Pictures of Corrugated Aluminum Sheet for Silo Structure:

- Q: Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination is a process of bonding multiple layers together to create a composite material with enhanced properties. In the case of aluminum sheets, they can be laminated with other materials such as plastics, adhesives, or even other metals. This process can improve the strength, durability, and thermal or electrical conductivity of the aluminum sheets. Laminated aluminum sheets are commonly used in various industries, including construction, automotive, aerospace, and packaging, where the combination of different materials provides the desired characteristics for specific applications.

- Q: What are the different types of patterns available for aluminum sheets?

- Aluminum sheets come in a wide range of patterns, each with its own unique visual and functional appeal. Here are some popular patterns that you can find: 1. Diamond Pattern: This pattern features raised diamonds created by intersecting parallel lines at 60-degree angles. It offers excellent slip resistance and is commonly used for flooring, stairs, and walkways. 2. Stucco Pattern: The stucco pattern mimics the texture of traditional stucco plaster, with a pebble-like surface. It provides enhanced durability and is often used decoratively on walls, ceilings, and interior panels. 3. Hammered Pattern: The hammered pattern creates a rustic and artistic appearance with its dimpled texture. It is frequently used for decorative purposes, such as wall cladding or furniture accents. 4. Perforated Pattern: Perforated aluminum sheets have small holes that offer great ventilation and visibility. They are commonly used in architectural applications like facades, sunscreens, and noise barriers. 5. Embossed Pattern: The embossed pattern adds depth and visual interest with raised designs or patterns on the sheet's surface. It is ideal for decorative purposes, signage, and branding applications. 6. Brushed Pattern: The brushed pattern creates a sleek and modern look by giving the aluminum sheet a uniform directional grain. It is often used for architectural accents, kitchen backsplashes, and appliances. 7. Ribbed Pattern: The ribbed pattern features parallel raised ridges or lines on the sheet's surface, offering improved strength and rigidity. It is suitable for applications that require structural support or reinforcement. These examples showcase the variety of patterns available for aluminum sheets. When selecting the right pattern for a specific application, it is essential to consider the specific requirements and desired aesthetic.

- Q: Is aluminum suitable for projects with heavy traffic or frequent use?

- <p>Yes, aluminum sheets can be used in projects that involve high levels of traffic or heavy use. Aluminum is a lightweight, durable, and corrosion-resistant material. It can withstand significant wear and tear, making it suitable for high-traffic areas. Additionally, aluminum is easy to maintain and can be recycled, which is beneficial for long-term projects. However, it's important to consider the specific grade of aluminum and its thickness to ensure it meets the required strength and durability for your project.</p>

- Q: What are aluminum sheets?

- Aluminum sheets are thin flat pieces of aluminum that are commonly used in various industries for applications such as construction, automotive manufacturing, packaging, and aerospace. They are versatile, lightweight, and durable, making them ideal for a wide range of purposes.

- Q: In which autocomponents usage of aluminium is better or otherwise?

- Aluminium is lighter as well as stronger than CI. Thats the reason most of the Automobile manufacturers use Aluminium for car bodies while they use cast iron for the underframes and internal chassis....NMN

- Q: Are 101 aluminum sheets suitable for heat sinks?

- 101 aluminum sheets are not appropriate for heat sinks, as heat sinks are intended to disperse heat and therefore necessitate materials with high thermal conductivity. In comparison to other aluminum alloys often employed for heat sinks, like 6061 or 6063, 101 aluminum possesses inferior thermal conductivity. These alloys exhibit superior thermal conductivity characteristics, enabling them to effectively transfer heat away from the heat source. Consequently, it is advisable to utilize aluminum alloys that are specifically engineered for heat sinks to guarantee optimal heat dissipation and cooling performance.

- Q: Are 101 aluminum sheets suitable for high-temperature applications?

- No, 101 aluminum sheets are not suitable for high-temperature applications. 101 aluminum is a pure aluminum alloy with excellent corrosion resistance and good formability, but it has a low melting point of 660 degrees Celsius (1220 degrees Fahrenheit). High-temperature applications typically require materials with higher melting points and better heat resistance, such as stainless steel or high-temperature alloys. Using 101 aluminum sheets in high-temperature environments could result in deformation, melting, or failure of the material, which could compromise the integrity and safety of the application.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum is a good choice for insulation jackets as it is lightweight, durable, and has excellent thermal conductivity. It can effectively reflect heat and prevent heat transfer, making it an efficient material for insulation purposes.

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

- Q: what kind of abradant should be used in the deburring of aluminum sheets? How to grind?

- you can use deburring brush,grinding fluid,abrasive powder and other consumables.

Send your message to us

Aluminum Camper Sheets for Corrugated Silo Structures

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords