Aluminum Sheets for Travel Trailers - Best Quality Aluminum Alloy Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Alloy Sheet

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

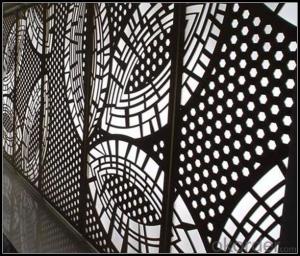

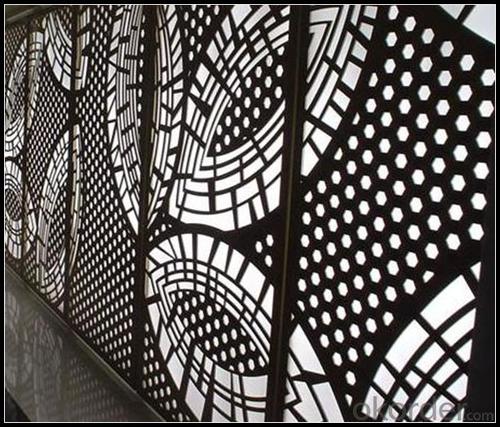

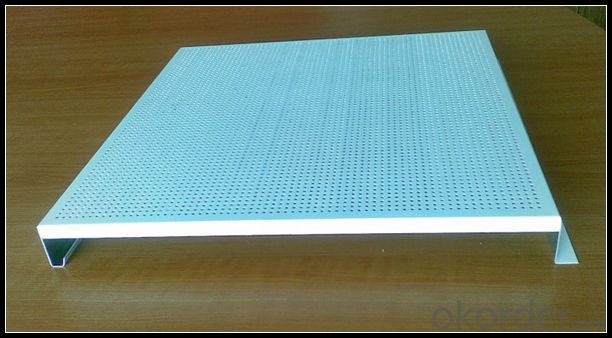

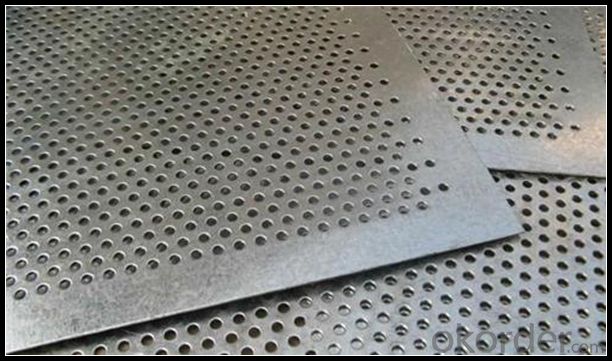

2. Application of Aluminum Alloy Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Alloy Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

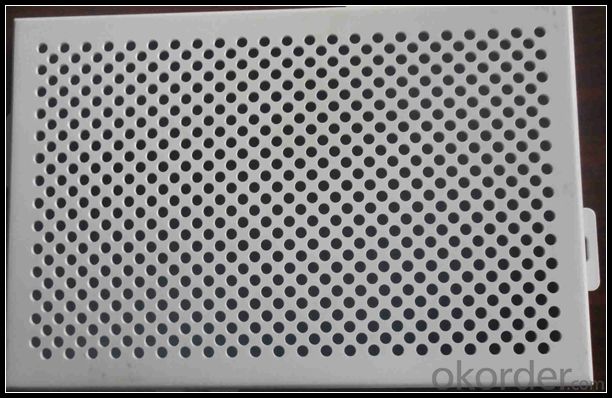

5. Image of Aluminum Alloy Sheet

6. Package and shipping of Aluminum Alloy Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- Yes...All Aluminium Macbooks are now turned to Macbook Pros. So might want to try the Mid 2009 white macbook or you have to go with 13 Macbook Pro... vist www.parithi for details..

- Q: Which kind of glue is best for bonding aluminum sheets?

- 502

- Q: Can the aluminum sheets be used for manufacturing electronic heat sinks?

- Yes, aluminum sheets can be used for manufacturing electronic heat sinks. Aluminum is a popular choice for heat sink material due to its excellent thermal conductivity and lightweight properties. It efficiently transfers heat away from electronic components, helping to dissipate and manage heat generated during operation. Aluminum sheets can be easily formed and shaped into the desired heat sink design, providing effective cooling for electronic devices.

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks as they lack the necessary corrosion resistance for handling and storing chemicals.

- Q: why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q: some car manufactures use aluminium car body on a steel sub-frame. explain, using electrode potential what would happen if a weak acid was to become trapped in the space between these two metals!! any current plzz help, its for my assignment, and i dont understand

- Most reactive metal will corrode first.

- Q: Is it suitable to use aluminum sheets in outdoor settings where they will be subjected to weather conditions?

- <p>Yes, aluminum sheets can be used for outdoor applications, even when exposed to weathering. Aluminum is a durable and corrosion-resistant material, which makes it suitable for outdoor use. It does not rust like iron or steel and can withstand various weather conditions. However, it's important to use aluminum alloys specifically designed for outdoor use, and to apply protective coatings or finishes to enhance its resistance to weathering and extend its lifespan.</p>

- Q: Are the aluminum sheets suitable for manufacturing marine propellers?

- Indeed, aluminum sheets prove to be a fitting choice for the production of marine propellers. The lightweight and rust-resistant nature of aluminum render it exceptionally well-suited for deployment in maritime settings, where propellers endure continuous exposure to water and severe circumstances. Aluminum propellers possess numerous benefits, encompassing an elevated ratio of strength to weight, heightened fuel effectiveness, and diminished maintenance expenses. Furthermore, as opposed to materials like stainless steel or bronze, aluminum emerges as a cost-efficient alternative. Consequently, the utilization of aluminum sheets emerges as an apt selection for the manufacturing of marine propellers.

- Q: How are aluminum sheets cut or shaped?

- Aluminum sheets can be cut or shaped using various methods depending on the desired outcome. One common method is using a saw, such as a circular saw or a bandsaw, with a carbide-tipped blade specifically designed for cutting metal. This allows for straight cuts and can be used for both thin and thick aluminum sheets. Another method is using a shear, which is a machine that uses sharp blades to cut the aluminum sheet. Shearing is ideal for cutting straight lines quickly and efficiently, especially for thinner sheets. For more intricate shapes or curves, aluminum sheets can be cut using a water jet cutter or a laser cutter. Water jet cutting involves using a high-pressure jet of water mixed with an abrasive material to cut through the sheet. Laser cutting, on the other hand, uses a focused laser beam to melt or vaporize the aluminum, resulting in precise and intricate cuts. In addition to cutting, aluminum sheets can also be shaped through processes like bending, rolling, or stamping. Bending involves using a press brake to bend the sheet into the desired angle or shape. Rolling, on the other hand, uses a rolling machine to gradually shape the sheet into curves or cylinders. Lastly, stamping involves pressing the sheet against a die to create specific shapes or patterns. Overall, the method used to cut or shape aluminum sheets depends on the thickness of the sheet, the desired outcome, and the available equipment.

Send your message to us

Aluminum Sheets for Travel Trailers - Best Quality Aluminum Alloy Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords