Aluminum 1in Thick Sheets AA5754 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets AA5754 Used for Construction Description

Aluminum Sheets AA5754 has great ductility, heat conductivity, anti-corrosion and moisture resistance properties which are very useful in the field of construction.

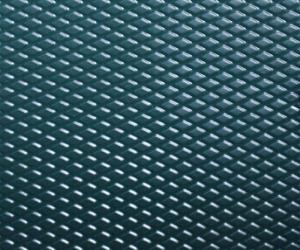

Aluminum Sheets AA5754is widely used for decorative purpose in construction, packing and appiance. It is also very commonly used for anti-slippery purpose in vehicles and public places.

2.Main Features of Aluminum Sheets AA5754 Used for Construction

• High weather resistance

• Anti scratch anticorrosion

• Subtle edges and elegant appearance

• High brightness and hardness.

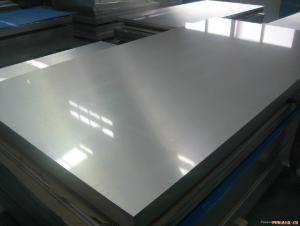

3.Aluminum Sheets AA5754 Used for Construction Images

4.Aluminum Sheets AA5754 Used for Construction Specification

Alloy | AA5754 |

Temper | H14, H16, H24,H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA5754 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA5754 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA5754 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

C/ What is the package?

Standard seaworthy export packing: wooden pallets with plastics protection

- Q: This question asks for signs or methods to identify if a building is utilizing aluminum sheets in its construction or design.

- <p>To determine if a building is using aluminum sheets, look for the following signs: 1) Shiny, metallic appearance, which is characteristic of aluminum. 2) Lightweight construction, as aluminum is less dense than many other metals. 3) Resistance to corrosion and weathering, a common feature of aluminum. 4) Use in areas prone to water or moisture, as aluminum is water-resistant. 5) Check for the manufacturer's specifications or building materials list. If possible, consult with the building's architect or engineer for confirmation.</p>

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Are 101 aluminum sheets suitable for marine environments?

- Indeed, marine environments are indeed suitable for 101 aluminum sheets. Recognized for its exceptional corrosion resistance, 101 aluminum is a high-strength alloy that proves to be perfect for marine applications. It can endure the harsh circumstances of saltwater, including exposure to salt spray and water immersion, without undergoing corrosion or deterioration. Furthermore, 101 aluminum possesses commendable weldability and formability, enabling it to be effortlessly shaped into a multitude of marine components like boat hulls, decks, and equipment. The strength, durability, and corrosion resistance of 101 aluminum sheets establish them as a dependable option for marine environments.

- Q: Aluminum is put into copper chloride and how can you tell what happens to them visually?

- appropriate you're watching basically worry-unfastened atoms of rely. Protons are somewhat charged debris, the quantity of protons an atom has determines the form of atom itself. for example one proton is hydrogen, six protons is for carbon, etc. The neutrons are have not have been given any can charge in an atom, and help stabilize the atom. undergo in techniques like expenses repel eachother, neutrons carry the protons at the same time. They the two have basically approximately the comparable mass. finally electrons have a adverse can charge and bypass around atoms in unpredictable techniques. The closer the kind of electrons there are in an atom to protons, the greater impartial that's. An atom is impartial at the same time as there are 8 valence electrons indoors the outer shell distinctive than fir helium with basically 2. undergo in techniques, that's basically your undertaking-loose grade 9 stuff, now no longer the actual fact i understand.

- Q: I have a friend to purchase a number of aluminum, used to make computer cooling plate. He asked me to help with the supplier, can I look at the Internet, there are many kinds of aluminum, would like to ask: what kind of computer cooling plate used to do a bit better? What are the suitable suppliers in Guangdong?

- Copper heat conductivity is good, but the price is more expensive, difficult to process, the weight is too large (a lot of pure copper radiator is beyond the limit of CPU), the heat capacity is small, and easily oxidized. The pure aluminum is too soft, can not directly use, are the use of aluminum alloy to supply enough hardness, aluminum alloy is the advantage of low prices, light weight, but the heat conductivity is much worse than copper. Some of the radiator embedded in a copper plate in each in his element, Aluminum Alloy radiator base.

- Q: I'm thinking of starting raised beds for a vegetable garden. I'm thinking about a shallow aluminum stock tank, about 12 in. deep x 4 ft. long. Having limited sunlight available, these could be moved around the yard and tended to easily. Any ideas? Aluminum with soil? Any effects? Holes will be drilled in the bottom for drainage. Thanks!

- They work great !

- Q: How are aluminum sheets measured and specified?

- When it comes to aluminum sheets, their thickness, width, and length are typically used for measurement and specification. The gauge, which is the thickness of the sheet, is commonly measured in inches or millimeters. The width and length, also measured in inches or millimeters, are also specified. To determine the thickness of an aluminum sheet, a gauge is utilized. This gauge serves as a standardized tool for measuring the sheet's thickness. The lower the gauge number, the thicker the sheet. For instance, a 10-gauge aluminum sheet is thicker compared to a 16-gauge sheet. In terms of the width and length of an aluminum sheet, they are usually measured in inches or millimeters. The width pertains to the horizontal measurement of the sheet, while the length refers to the vertical measurement. These dimensions play a crucial role in determining the size of the sheet and its suitability for specific applications. Aside from the gauge, width, and length, aluminum sheets can also be specified based on their alloy composition or temper. The alloy composition indicates the specific combination of metals present in the sheet, such as aluminum-magnesium, aluminum-zinc, or aluminum-copper alloys. The temper, on the other hand, refers to the heat treatment process that the sheet has undergone, which affects its mechanical properties, including hardness and flexibility. In conclusion, the measurement and specification of aluminum sheets primarily involve their thickness (gauge), width, and length. These measurements, along with additional specifications like alloy composition and temper, are essential in ensuring the appropriate selection and use of aluminum sheets for various applications in industries such as construction, automotive, aerospace, and more.

- Q: Are aluminum sheets suitable for solar reflectors?

- Certainly, solar reflectors can indeed make use of aluminum sheets. The construction of solar reflectors extensively relies on aluminum owing to its remarkable reflectivity and durability. By virtue of its reflective characteristics, aluminum effectively redirects sunlight onto solar panels or other solar equipment, thereby enhancing energy absorption. Moreover, aluminum is lightweight and resistant to corrosion, making it an excellent choice for outdoor use. Furthermore, its cost-effectiveness and ease of fabrication greatly contribute to its widespread adoption in the solar sector.

- Q: What are the effects of aluminum sheet manufacturing on the environment?

- <p>Aluminum sheet manufacturing factories can have significant environmental impacts. The process involves high energy consumption, which contributes to greenhouse gas emissions and climate change. Additionally, the production process can generate various pollutants, including particulate matter and hazardous chemicals, which can contaminate air and water resources. Land degradation can also occur due to mining activities for bauxite, the primary raw material for aluminum. Moreover, improper disposal of aluminum waste can lead to soil and water pollution. However, with advancements in technology and sustainable practices, the industry is making efforts to reduce its environmental footprint.</p>

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

Send your message to us

Aluminum 1in Thick Sheets AA5754 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords