Acm Aluminum Sheets for Trailers Tanker Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheeting for Trailers Tanker Making

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Sheeting for Trailers Tanker Making

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

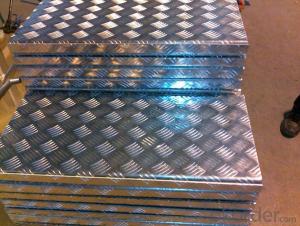

3. Aluminum Sheeting for Trailers Tanker Making Images

4.Specification of Aluminum Sheeting for Trailers Tanker Making

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- While I fortunately have not been hit with either, I would think the wooden bat, with its increased weight, could be swung more forcefully and would hurt more.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- 1. This depends on the aluminium particle size and it's quality as Al is normally coated with an oxide layer that protects the Al metal underneath. Assuming that the Al powder was good stuff, it should react as violently as the Zn and Mg mixtures. Why .. because it is a very reactive metal ... see further info below. However I needed tried it. 2. The difference is really about the reactivity. Iron, although a reactive metal, is far less reactive than Mg,Al, and Zn. I have tried the zinc and sulphur a number of times and it is really quite violent. With a fair quantityof reactants in the lab it produced an excellent mushroom smoke cloud. I've also seen the Al reactivity demonstrated by a mad Chemistry prof from Nottingham University. He mixed Al powder into a paste with liquid oxygen and ignited it! Wow ... what a reaction.I shall never forget it although it was about 35 years ago!

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: What are aluminum sheets used for?

- Aluminum sheets are widely used for various applications such as building facades, roofing, automotive parts, aircraft components, packaging materials, electrical wiring, and heat exchangers due to their lightweight, corrosion-resistant, and malleable properties.

- Q: Can aluminum sheets be used for chemical storage containers?

- Yes, aluminum sheets can be used for chemical storage containers. Aluminum is known for its excellent corrosion resistance, which makes it suitable for storing a wide range of chemicals. It is also lightweight, durable, and non-reactive with most substances, making it a popular choice for chemical storage applications. Additionally, aluminum is easily formed and fabricated into various shapes and sizes, allowing for customized container designs. However, it is important to consider the specific chemical being stored and consult with experts to ensure compatibility and safety.

- Q: i know what aluminum is but oxide is not found on the periodic table, and the teacher also gave us a list of common oxidation numbers for polyatomic ions and it is not there also, can anyone help me?

- oxide means oxygen.. atomic mass of roughly 16. Al2O3 so 2 Al which has an atomic mass of 27 each and then three O which have an atomic mass of 16 each.. so add it up and you get 102

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- Strange... okorder /

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: Can aluminum sheets be used for architectural applications?

- Yes, aluminum sheets can definitely be used for architectural applications. Aluminum is a versatile and lightweight material that offers numerous advantages for architectural projects. Its durability, corrosion resistance, and ability to withstand extreme weather conditions make it ideal for various architectural applications such as roofing, cladding, facades, windows, doors, and decorative elements. Aluminum sheets are available in a wide range of thicknesses, finishes, and colors, allowing architects and designers to achieve their desired aesthetic while maintaining structural integrity. The material can be easily shaped, bent, and formed into complex designs, providing flexibility and creative freedom to architects. In addition to its aesthetic appeal, aluminum is also a sustainable choice for architectural applications. It is a highly recyclable material, with a high recycling rate, making it an environmentally friendly option. Using aluminum sheets in architectural projects can contribute to reducing the carbon footprint and promoting sustainable design practices. Furthermore, aluminum sheets offer excellent thermal and acoustic properties, contributing to energy efficiency and sound insulation in buildings. The material can help reduce energy consumption and enhance occupant comfort, making it an attractive choice for architects and building owners. Overall, aluminum sheets are a popular choice in architectural applications due to their versatility, durability, sustainability, and aesthetic appeal. They offer numerous benefits and can be used in various ways to create stunning architectural designs while ensuring long-lasting performance.

Send your message to us

Acm Aluminum Sheets for Trailers Tanker Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords