Aluminum Square Sheets Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

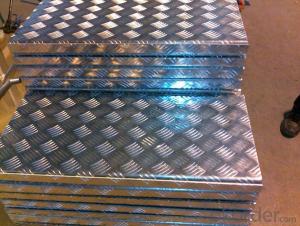

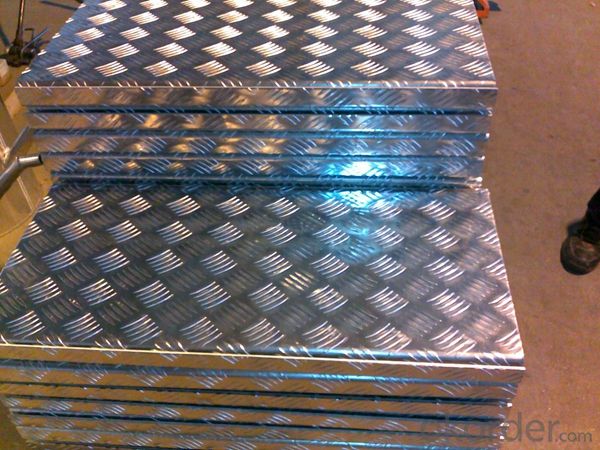

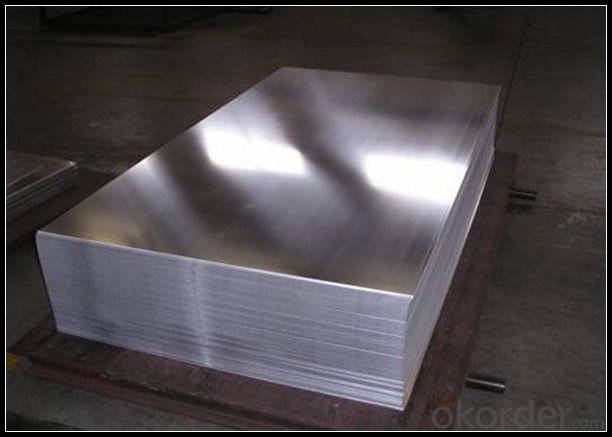

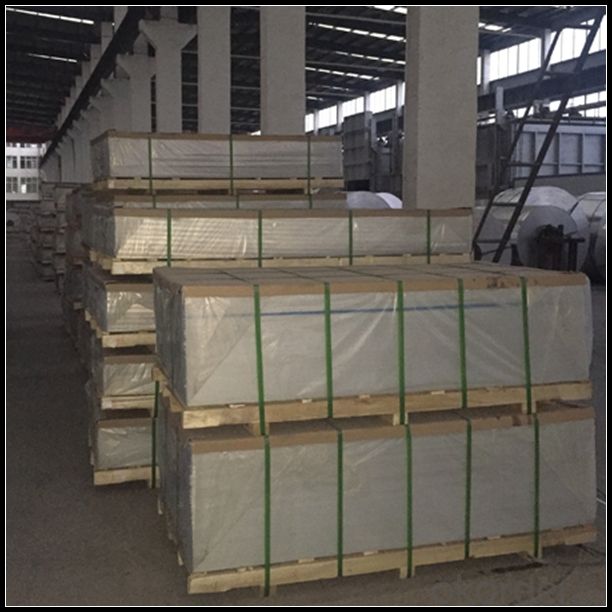

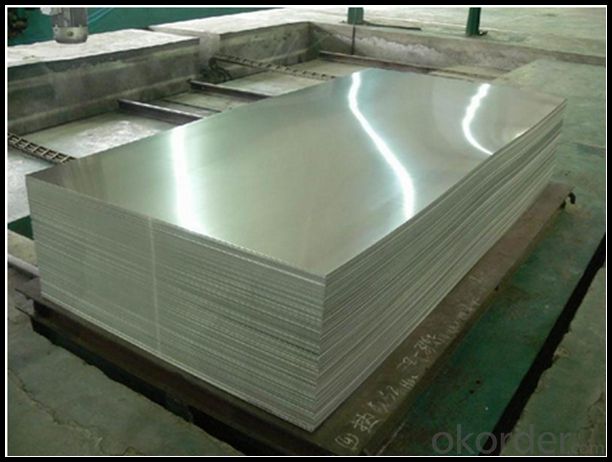

5. Image of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

6. Package and shipping of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do you prevent surface marring of aluminum sheets during handling?

- To prevent any damage to the surface of aluminum sheets when handling them, there are several steps that can be taken: 1. Use clean gloves or finger cots: It is important to avoid direct contact between bare hands and the aluminum sheets, as hands can contain oils, dirt, or other contaminants that may leave marks on the surface. Wearing clean gloves or finger cots acts as a barrier and prevents any transfer of substances onto the sheets. 2. Utilize protective packaging: Before handling the sheets, consider using protective packaging such as foam or plastic sheets to cover the surface. This provides an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store the aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure they are lifted or supported evenly to prevent bending or distortion that could lead to surface damage. Using appropriate lifting equipment, such as suction cups or clamps, helps distribute the weight evenly and minimizes the risk of harm. 4. Regularly clean the surface: Clean the aluminum sheets on a regular basis using a mild detergent or cleaning solution specifically designed for aluminum. This removes any dirt, grime, or other substances that could potentially cause surface damage. Ensure soft, non-abrasive cleaning tools like microfiber cloths or sponges are used to avoid scratching. 5. Implement quality control measures: Establish quality control measures during the handling process to identify any potential causes of surface damage. Conduct regular inspections to check for signs of harm or defects. Properly train employees involved in the handling process to minimize the risk of surface damage. By following these preventive measures, the chances of surface damage to aluminum sheets during handling are significantly reduced, ensuring they remain in pristine condition and maintain their quality.

- Q: what’s the difference of activated aluminum and aluminum sheet?

- you can use weak acid ,weak base solvent or steam to clean the oil and dirt on the surface, it's activated aluminum, their difference is that activated aluminum has porous structure oxide film.

- Q: Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting.

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a commonly used material in the electrical industry due to its excellent conductivity, corrosion resistance, and lightweight properties. It provides good shielding against electromagnetic interference and is easy to fabricate into various shapes and sizes for enclosures.

- Q: Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets can be used in the aerospace industry. Aluminum is a lightweight material with excellent strength-to-weight ratio, making it a popular choice for various aerospace applications. It is commonly used in the construction of aircraft structures, such as fuselages, wings, and panels. The use of aluminum sheets in the aerospace industry offers several benefits, including reduced fuel consumption due to the weight savings, improved maneuverability, and increased payload capacity. Additionally, aluminum exhibits good corrosion resistance, which is crucial for aircraft exposed to harsh environmental conditions. Overall, aluminum sheets are widely utilized in the aerospace industry for their favorable properties and performance.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: I heard somewhere that when aluminum is heated, it releases something that is a known cause of Alzheimers. Is this true? I have a homemade cooker made of aluminum and I don't want Alzheimers.

- They felt that used to be the case because of the aluminum seeping into the food. Hard to find an uncoated aluminum pot now. You get more aluminum from deodorants and antacids than cookware. You shouldn't though cook or store tomatoes in aluminum...and that's just the reaction in chemistry.

- Q: This question asks for a comparison of the cost of aluminum sheets with other building materials.

- <p>Aluminum sheets are generally considered cost-effective compared to other building materials, especially when considering their long-term benefits. They are relatively inexpensive to produce and install, and their low maintenance requirements can save costs over time. However, their initial cost may be higher than some materials like wood or vinyl. Aluminum's resistance to corrosion and weathering means it lasts longer, which can offset the higher upfront cost. In contrast, materials like steel might be more expensive due to their weight and the cost of corrosion protection, while concrete and masonry are typically more costly for both materials and labor. The cost-effectiveness of aluminum can vary based on regional prices, specific project requirements, and the type of aluminum product (e.g., thickness, finish).</p>

- Q: I was quoted $5000+ to upgrade my house from 100A electric service to 400A. Part of the reason for the high cost is the cost of copper. What size copper wire is needed for 400A, and how much does it cost per foot? Would it be a lot cheaper to use aluminum wire?

- Oh come on!! The question seems to be asking abotu replacing the service ENTRY cable to bump it up from 100 to 400 AMPS. Got news for you all. THe service entrace cable IS aluminum. It connects to the circuit breaker box at terminals designed FOR aluminum. Go take a look at any recent install and tell me what you see. (It will be AL) AS for the remainign wires throughout the house. Most will be copper. However note that modern outlets can be provided to accept aluminum and copper. Just look fot the AL/CU stamp ont he outlet. Generally the clothes dryer, over and A/C will use al wire but they are attached to outlets specifically designed for AL wire. Eric

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

Send your message to us

Aluminum Square Sheets Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords