Checkered Aluminium Sheets AA5083 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Sheets AA5083 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminium Sheets AA5083 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheets AA5083 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

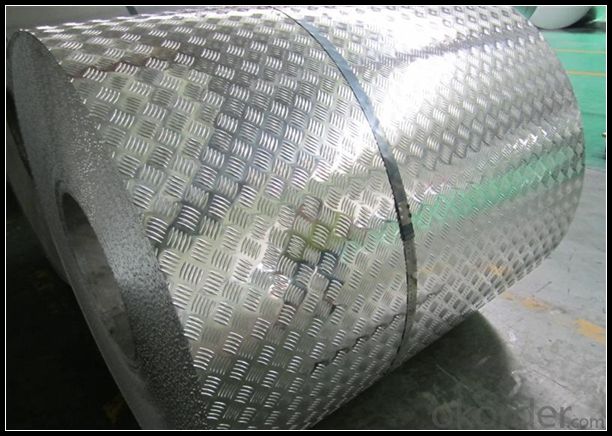

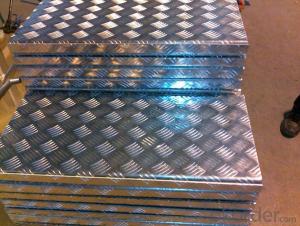

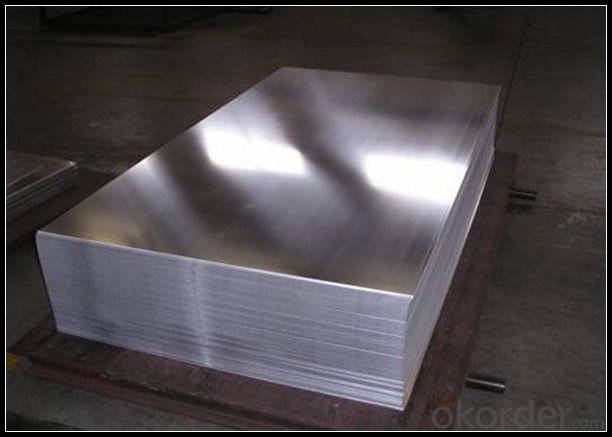

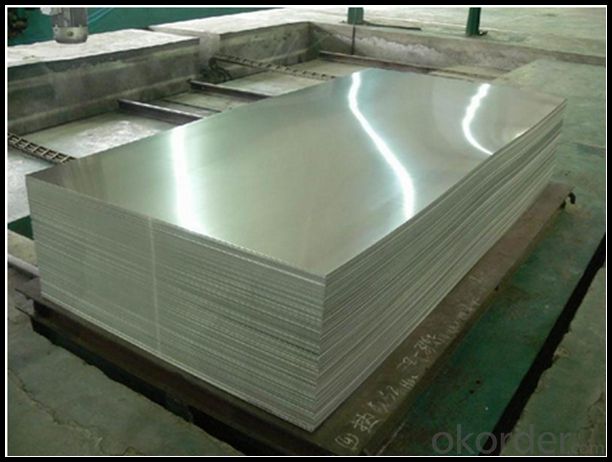

5. Image of Checkered Aluminium Sheets AA5083 for Making Aluminium Trailers

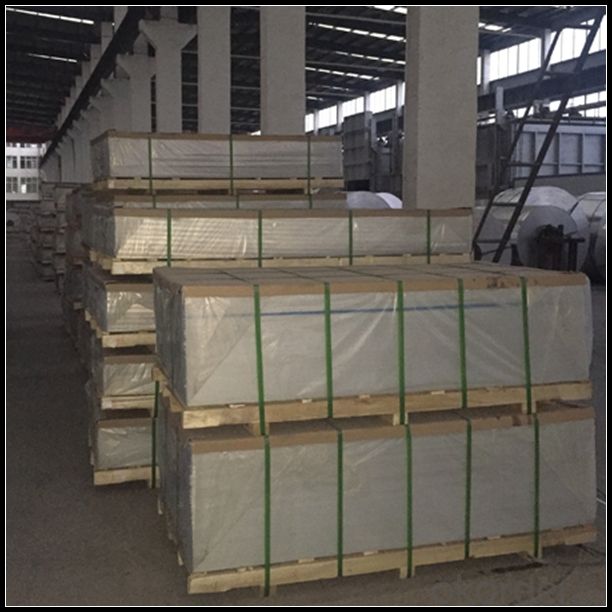

6. Package and shipping of Checkered Aluminium Sheets AA5083 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding due to their durability, lightweight nature, and corrosion resistance. Additionally, aluminum offers versatility in terms of design options and ease of installation, making it a popular choice for cladding applications in various industries.

- Q: I know that aluminum doesn't belong in the human body. As a canister to hold liquids which will be consumed later, is aluminum good or bad to use?

- aluminum cans have a plastic coating on the inside to prevent poisoning aluminum is bad for you

- Q: Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes through a process called extrusion.

- Q: Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Hot dip aluminizing applicationsAluminized steel is widely used. The type I aluminized steel plate, originally developed, is mainly used in automobile exhaust pipes and silencers. Type II is used mainly for roofing and side walls of buildings, as well as for chemical containers. The aluminized steel wire produced by the new process is expected to be used as the core of the transmission line instead of the galvanized steel wire. Aluminized steel pipe has been widely used in power plants, boilers, water wall tubes, steam pipes, heat exchangers and so on. Aluminized steel structure has been widely used in power transmission tower, told highway guardrail and so on.

- Q: I know aluminium forms a protective layer of aluminum oxide and hence water does not corrodes it easily.However, since the oxide is amphoteric, won't it react with acids and subsequently be dissolved?What is the main reason aluminium cans are used?

- because they are light and easy to smash with your hand

- Q: Are aluminum sheets suitable for bulletproof applications?

- No, aluminum sheets are not suitable for bulletproof applications.

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- Embedded aluminum roof flashing, aluminum water stops, aluminum electrical conduit, introduced aluminum powder (sometimes used to foam concrete), or embedded structural aluminum shapes may all corrode in concrete or mortar. In all cases, a reaction that forms aluminum hydroxide and hydrogen gas occurs, and may cause expansion and cracking of the concrete or mortar. The common use of calcium chloride (or other alkali compounds), and dampness of the concrete increases the reaction rate. Usually, coating the aluminum with bituminous paint, impregnated paper or felt, plastic, or an alkali-resistant coating will prevent or sharply reduce the corrosion.

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Spray Painting Aluminum

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

Send your message to us

Checkered Aluminium Sheets AA5083 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords