304 4x8 Stainless Steel Sheet Metal Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 4x8 Stainless Steel Sheet Metal Price

1.Product Description

1. Specifications about stainless steel sheet

Commodity430 304 304L 316L 201 316 4x8 sheet metal prices stainless steel

Grade201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L

BrandTISCO ,BAOSTEEL,POSCO,JISCO,LISCO

CertificationSGS,BV,IQI,TUV,ISO,etc

Thickness0.2mm-150mm

Width1000,1219,1250,1500mm, or as your requirements

Length2000,2438,2500,3000,6000mm, or as your requirements

SurfaceNo.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film.

StandardASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc

Delivery time5-7 days after confirming the order

MOQ1 Ton

AdvantagesShowing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste.

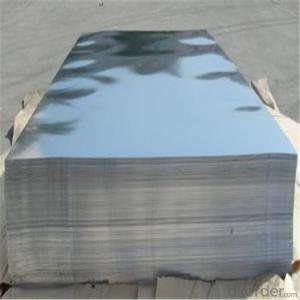

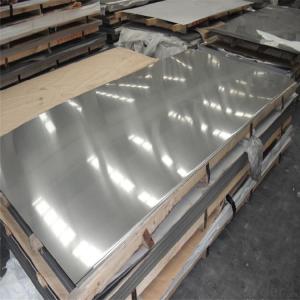

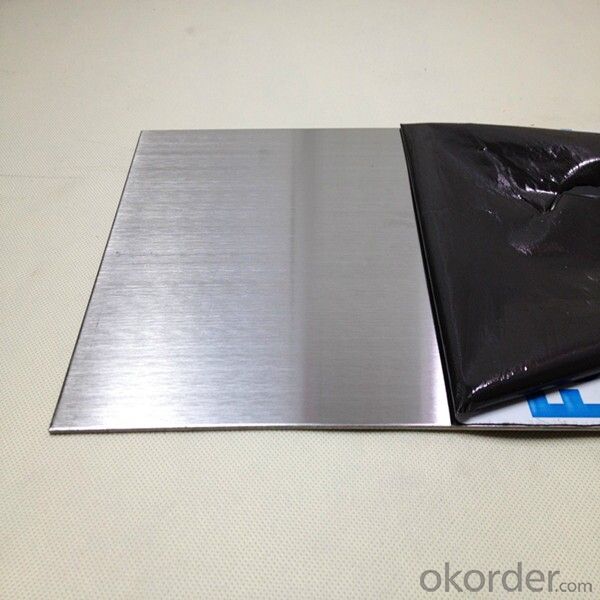

2.Products photos

3.FAQ

1.Small quantity, short time delivery

If we have stocks, the delivery time is less than 7 days,If the quantity is more than 500Tons,the delivery time is abou 30 days after confirming the order.

2.Choose the appropriate metals stainless steel for your needs.

We carefully balance quality, delivery time and price,procure various grades metals from all over the world.

3.Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

We assure you:

Small MOQ + Cheap Price + Fantastic Quality + Fast Delivery

- Q: How do you prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, there are several measures you can take. 1. Regular Cleaning: Proper and regular cleaning is essential to prevent discoloration on stainless steel sheets. Use mild soap or detergent and warm water to clean the surface. Avoid using abrasive cleaners or scrubbing pads as they can cause scratches that may lead to discoloration. 2. Avoid Harsh Chemicals: Avoid using harsh chemicals or cleaners containing chlorine, bleach, ammonia, or acids as they can cause pitting or corrosion on the stainless steel surface, leading to discoloration. Stick to mild and non-abrasive cleaners specifically designed for stainless steel. 3. Rinse Thoroughly: After cleaning, make sure to rinse the stainless steel sheet thoroughly with clean water to remove any residue from the cleaning solution. Residual chemicals can cause discoloration if left on the surface for an extended period. 4. Dry Completely: After cleaning and rinsing, it is important to dry the stainless steel sheet completely. Moisture left on the surface can lead to water spots or staining, especially in environments with hard water. Use a soft cloth or towel to remove all moisture, ensuring a dry and shiny surface. 5. Protective Coatings: Applying protective coatings or sealants designed for stainless steel can help prevent discoloration. These coatings create a barrier that protects the surface from environmental factors, such as humidity, oxidation, and staining. 6. Proper Handling and Care: Avoid dragging or sliding objects across stainless steel sheets, as this can cause scratches or abrasions that may lead to discoloration. Handle the sheets with care, using clean gloves or a soft, non-abrasive cloth to minimize the risk of surface damage. 7. Regular Maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Promptly address any issues by following the appropriate cleaning and maintenance procedures to prevent further damage and maintain the appearance of the stainless steel. By following these preventive measures, you can effectively minimize discoloration on stainless steel sheets and keep them looking clean, shiny, and stain-free for a longer period.

- Q: Can stainless steel sheets be used for electrical conductivity?

- Typically, stainless steel sheets are not employed for electrical conductivity. Stainless steel is renowned for its exceptional resistance to corrosion and durability, rendering it apt for a diverse range of applications like kitchen appliances, construction materials, and industrial equipment. Nevertheless, stainless steel falls short in terms of conductivity compared to metals such as copper or aluminum. Consequently, materials with superior electrical conductivity properties are commonly preferred for electrical purposes.

- Q: How high is the temperature of 2520 stainless steel?

- For Ni (Ni), chromium (Cr) content is high, with good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature performance, high temperature resistant steel dedicated to the manufacture of electric furnace tube and so on, increase the amount of carbon austenitic stainless steel, due to the solid solution strengthening effect to the strength improved, chemical composition characteristics of austenitic stainless steel is chrome, nickel based addition of molybdenum and tungsten, niobium and titanium elements, as its face centered cubic structure, and strength and high creep strength at high temperature.

- Q: How do stainless steel sheets differ from other types of metal sheets?

- Stainless steel sheets differ from other types of metal sheets in several ways. Firstly, stainless steel is an alloy that contains a minimum of 10.5% chromium. This chromium content forms a protective layer of chromium oxide on the surface of the metal, making it highly resistant to corrosion and staining. This unique property sets stainless steel sheets apart from other metals, as they can withstand exposure to harsh environments, chemicals, and moisture without deteriorating. Secondly, stainless steel sheets offer excellent strength and durability. Due to their composition, stainless steel sheets are highly resistant to heat, impact, and wear. This makes them suitable for a wide range of applications, including automotive, construction, and industrial settings, where strength and endurance are crucial. Another important distinction is the aesthetic appeal of stainless steel sheets. They have a sleek and modern appearance, which is highly sought after in architectural and interior design projects. Stainless steel sheets can be easily polished to a mirror-like finish, adding an elegant touch to any space. Moreover, stainless steel sheets are known for their hygiene and cleanliness. They have a non-porous surface that does not absorb moisture, making them resistant to bacteria, mold, and other contaminants. This makes stainless steel sheets the material of choice for kitchen appliances, food processing equipment, and medical devices. Lastly, stainless steel sheets are highly customizable. They can be manufactured in various thicknesses, sizes, and finishes to meet specific requirements. Additionally, stainless steel can be easily formed, welded, and fabricated, allowing for creative designs and customization options. In summary, stainless steel sheets differ from other types of metal sheets due to their exceptional corrosion resistance, strength, durability, aesthetic appeal, hygiene, and customization options. These unique characteristics make stainless steel sheets a versatile and reliable choice for a wide range of applications.

- Q: What are the common uses of stainless steel sheets in the food industry?

- Stainless steel sheets are widely used in the food industry due to their numerous beneficial properties. One common use of stainless steel sheets in the food industry is for food processing equipment. These sheets are used to fabricate machines such as mixing tanks, conveyors, and food processing tables. Stainless steel sheets are preferred for this purpose because they are resistant to corrosion, easy to clean, and do not react with food substances, ensuring the food's safety and hygiene. Another common use of stainless steel sheets in the food industry is for food storage and transportation. Stainless steel sheets are often used to manufacture containers, tanks, and barrels that are used to store and transport food products. The corrosion resistance of stainless steel ensures that the food is protected from contamination and spoilage during storage and transportation. Stainless steel sheets are also used for kitchen equipment in the food industry. Countertops, sinks, and cabinets are frequently made from stainless steel sheets due to their durability, heat resistance, and ease of cleaning. These qualities make stainless steel sheets ideal for use in food preparation areas where hygiene is of utmost importance. Furthermore, stainless steel sheets are utilized in the construction of food service equipment such as ovens, grills, and refrigerators. These sheets are crucial in maintaining the desired temperature and preventing the growth of bacteria, ensuring that the food served is safe and of high quality. In summary, stainless steel sheets are commonly used in the food industry for food processing equipment, food storage and transportation, kitchen equipment, and food service equipment. Their corrosion resistance, easy maintenance, and ability to uphold hygiene standards make them an ideal choice for various applications in the food industry.

- Q: How do you remove fingerprints from stainless steel sheets?

- To remove fingerprints from stainless steel sheets, you can start by using a microfiber cloth or a soft cloth dampened with warm water and mild dish soap to gently wipe the surface. Then, rinse the cloth and wipe away any soap residue. If the fingerprints persist, you can try using a mixture of vinegar and water or rubbing alcohol on the cloth to further clean the stainless steel. Finally, make sure to dry the sheets thoroughly with a clean cloth to prevent water spots.

- Q: What is the maximum thickness of stainless steel sheets for bending?

- The maximum thickness of stainless steel sheets for bending can vary depending on the specific grade and type of stainless steel being used. In general, stainless steel sheets up to around 6mm thick can be easily bent, while thicker sheets may require specialized equipment and techniques for successful bending.

- Q: What are the different types of punched finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of punched finishes, each with distinct qualities and advantages. Let's explore some of the most commonly used options: 1. Round Hole: This punched finish, which features evenly spaced round holes, is highly versatile and widely utilized. It enables effective airflow and visibility and finds applications in ventilation systems, decorative panels, and filters. 2. Square Hole: With a clean and contemporary appearance, the square hole punched finish is often chosen when a more geometric pattern is desired. It is commonly employed in architectural projects, screens, and fencing. 3. Slotted Hole: The slotted hole punched finish is characterized by elongated holes, providing larger openings for enhanced visibility or improved drainage. It finds uses in grilles, sunshades, and safety barriers. 4. Hexagonal Hole: Offering an aesthetically pleasing pattern, the hexagonal hole punched finish showcases hexagon-shaped holes. It is commonly used in decorative applications like wall cladding, signage, and artistic installations. 5. Decorative Patterns: In addition to the standard punched finishes, stainless steel sheets can be customized with various decorative patterns, including personalized designs, logos, or intricate shapes. This allows for a unique and personalized touch in any project. When choosing a punched finish for stainless steel sheets, it is crucial to consider the specific requirements of the application, including aesthetics, functionality, and performance. Key factors to consider include hole size, open area percentage, strength, and corrosion resistance.

- Q: How do stainless steel sheets compare to other types of metal sheets?

- Stainless steel sheets have several advantages over other types of metal sheets. They are highly resistant to corrosion, making them suitable for various applications in industries such as automotive, construction, and food processing. Stainless steel sheets also offer exceptional strength and durability, ensuring long-lasting performance. Additionally, they have an attractive appearance, making them popular for aesthetic purposes. While stainless steel sheets may be slightly more expensive than other metal sheets, their numerous benefits make them a worthwhile investment.

- Q: Are stainless steel sheets easy to install?

- Yes, stainless steel sheets are relatively easy to install. They usually come in standard sizes and can be easily cut to fit specific dimensions if needed. Stainless steel sheets are lightweight and can be easily handled, making the installation process more convenient. Additionally, they often come with pre-drilled holes, which allows for easy attachment to various surfaces. With proper tools and basic knowledge of installation techniques, stainless steel sheets can be installed in a straightforward manner.

Send your message to us

304 4x8 Stainless Steel Sheet Metal Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 25000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords