Clear Plastic Sheets 4X8

Clear Plastic Sheets 4X8 Related Searches

Plastic Sheets 4X8 Hard Plastic Sheets 4X8 4 By 8 Plastic Sheets Polypropylene Sheets 4X8 Plexiglass Sheets 4X8 Clear Plastic Sheets 4X8 Tin Sheets 4X8 Metal Sheets Stainless Steel Sheets 4x8 4 X 8 Tin Sheets Sheet Metal Sheets 4X8 4X8 Styrofoam Sheets Stainless Steel 4x8 Sheets Stainless Steel 4x8 Sheet 4x8 Stainless Steel Sheet 4 X 8 Styrofoam Sheets Sheet Metal 4X8 4x8 Sheet Of Stainless Steel 8 X 4 6Mm Plywood Sheets 4X10 Plywood Sheets 4X8 Sheet Aluminum 6 X 8 Plywood Sheet Galvanized Steel Sheet 4x8 4 X 8 Sheet Of Stainless Steel Flat Plastic Sheets 3Mm Plywood Sheets 8X4 Lightweight Plastic Sheets 4X12 Plywood Sheets Diamond Plate Aluminum Sheets 4X8 Plastic Film SheetsClear Plastic Sheets 4X8 Supplier & Manufacturer from China

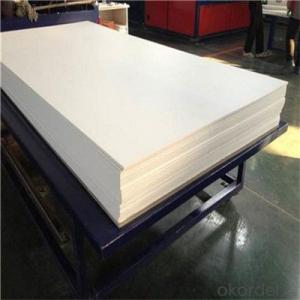

Clear Plastic Sheets 4X8 are versatile and durable plastic materials that come in a variety of thicknesses and types, suitable for a wide range of applications. These sheets are commonly used for protective coverings, signage, display cases, and various construction and DIY projects. The 4X8 size offers a good balance between coverage and manageability, making it a popular choice for both commercial and residential use. The clear plastic sheets provide excellent transparency, allowing for easy viewing and protection of items, while also being resistant to scratches and impacts.Clear Plastic Sheets 4X8 are widely used in various industries, such as retail, construction, and manufacturing, due to their ability to protect surfaces and items from damage, while still maintaining visibility. These sheets can be easily cut and shaped to fit specific needs, making them a popular choice for custom applications. In addition, their lightweight and flexible nature makes them easy to handle and install, further enhancing their appeal in various usage scenarios. Whether it's for creating a protective barrier around a valuable artwork or constructing a temporary shelter, Clear Plastic Sheets 4X8 offer a reliable and cost-effective solution.

Okorder.com is a leading wholesale supplier of Clear Plastic Sheets 4X8, boasting a large inventory that caters to the diverse needs of customers. By offering a comprehensive selection of sizes, thicknesses, and materials, Okorder.com ensures that customers can find the perfect Clear Plastic Sheets 4X8 for their specific requirements. With competitive prices and efficient shipping, Okorder.com is committed to providing top-quality products and exceptional service to its customers, making it a trusted source for Clear Plastic Sheets 4X8 and other plastic materials.

Hot Products