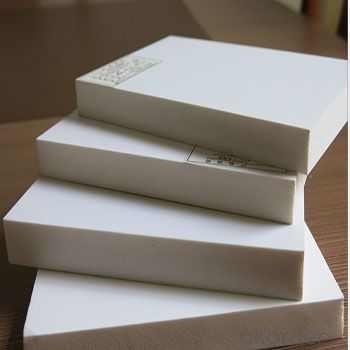

Plastic Sheets - 2024 New Fine White 4x8' 0.5mm Foam Sheet PVC for Factory Hot Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Material Introduction:

PVC is a strong, stiff, low cost plastic material that is easy to fabricate and easy to bond using adhesives or solvents.We know that PVC Sheet and Rod has an exceptional chemical resistance and has high mechanical and tensile strength combined with a high degree of stability which together makes this easily welded product one of the most versatile general purpose plastics available.

2. Material Introduction:

Excellent strength and toughness performance

Flame retarded

Weather resistant,water proof, acid proof, Resistant to chemicals and corrosion., Abrasive-resistant , Excellent UV resistance

Aging-resistant

3. Application:

Construction materials, industrial engineering, semiconductor processing equipment.

Machining: Cutting, sawing, turning, drilling, planing, milling, grinding & screwing.

Forming; Stretch forming, thermoforming, vacuum forming, blow moulding, bending, folding & punching

Welding;Hot-gas, heated-tool & folding.

Eviroment protection,chemical industry,mentallurgy of rare metals, extraction work of rare earth,

Stationery

Package

4. Main Properties of PVC:

1 | Size | 1000x2000mm, 1220x2440mm, 1500x3000mm, etc. |

2 | Thickness | 0.3mm to 60mm |

3 | Width | max 2000mm |

4 | Length | any length |

5 | Density | 1.45g/cm3 |

6 | Material | Polyvinylchloride (100% Virgin PVC Raw Material) |

7 | Type | Rigid PVC Sheet |

8 | Color | Clear, white, black, dark grey, light grey, green, blue, yellow, etc. |

9 | Surface | Smooth ,clean. |

10 | Type | Sheet and Roll are available |

11 | Certification | ISO9001:2000, RoHS |

12 | Packing | Inner packing: Plastic bag; Outer Packing: Carton |

PVC Foam Board Type

pvc celuka foam board, white pvc foam board,black pvc foam board,colored pvc foam board,red pvc foam board,yellow pvc foam board,green pvc foam board,blue pvc foam board and so on.our pvc foam sheet other name is pvc foam board, pvc foam panel, pvc foam plate,rigid pvc foam board,pvc free foam sheet ,pvc plastic foam sheet,pvc forex sheet,pvc crust foam sheet,pvc extruded foam sheet,hard foam pvc sheet,pvc celuka foam sheet,pvc cabinet foam sheet and so on.

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q3: Is free design assistance available for clients?

A3: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

Q4: What factors affect the price?

A4: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to

get exact quotation.

- Q: I am working on case modding my wii and I want to cut a stenciled design out of the plastic on the side. Is there a certain tool that can do this eficiently? im not sure a dremel would work with such an intricuite design (sorry for spelling) so which tool should i use?

- Anthony, I would use a spray glue (sold in the glue section of most stores) and spray the adhesive to the stencil and then apply to the plastic. It's simple to do, just follow directions on the can. Then if you have access to a scrollsaw, you can use a fine blade and cut the design with little trouble, no matter how intricate the design. Of course if you're unable to lay the area onto the flat surface of the scrollsaw, this won't be an option. If you use a dremel, it will be very difficult to follow the lines, plus it will leave a melted area along the cut lines. you could try using a plastic cutting knife, but if the detail is intricate, you won't have very good control. If the plastic is thick, it probably won't cut through the material. You may be able to use a coping saw, if the throat on the saw will clear the side of the plastic so you can cut it. You'd have to drill a starting point for the blade to enter. If the throat is not wide enough on the saw, try removing the blade from the saw and use it without the saw. The blade is very fine and should cut the material, including the intricate areas. That's about they only reliable ideas I can muster. Perhaps someone else has some ideas. good luck

- Q: What are the common applications of plastic sheets?

- Plastic sheets have a wide range of applications, including use in packaging materials, construction projects, automotive industry, signage and advertising, medical and healthcare products, electrical and electronics components, and even in arts and crafts.

- Q: How do plastic sheets handle drilling and cutting?

- Plastic sheets generally handle drilling and cutting quite well, as they can be easily pierced or shaped using standard tools such as drills, saws, or laser cutters. However, it is important to choose the appropriate type of plastic and use the correct technique to prevent cracking, melting, or other damage during the drilling or cutting process.

- Q: Are plastic sheets resistant to cracking under pressure?

- Yes, plastic sheets are generally resistant to cracking under pressure due to their flexibility and ability to withstand external forces without breaking.

- Q: What are the different thickness tolerances for plastic sheets?

- The different thickness tolerances for plastic sheets can vary depending on the specific type of plastic and its intended application. However, in general, common thickness tolerances for plastic sheets range from +/- 0.005 inches to +/- 0.030 inches.

- Q: Hi ! I want to print a double side sheet of transparent plastic , but the colors get all dizzy becaus of the transparancy , how can i print white on both sides of the plastic ?

- Actually, I had direct experience in using liquid watercolor (just superconcentrated pigment, I guess) I believe from Dick Blick, on yupo paper, which is pretty transparent, but a little cloudy-looking. You can't touch it without wearing rubber gloves at first though, or your paint will not stick to where the oils from your hands touched it. The paper comes pretty large, but I don't think it was quite that big, and I'm not sure where it was ordered from, but you may be able to find it online?? Good luck!

- Q: How thick are plastic sheets typically?

- Plastic sheets typically range in thickness from 0.25 millimeters to 12 millimeters, depending on the specific application and type of plastic used.

- Q: What do you put underneath sand so that it doesnt touch the ground. It is like a sheet.?

- A durable plastic is what landscapers use. They use this for mulch as well.

- Q: A proton (m= 1.67x10^-27kg) moving at 4.0x10^7m/s shoots through a sheet of foam plastic .25 cm thick and emerges with a speed of 1.5x10^7 m/s A) How long does it take to pass through the plastic?B) What average force retards the proton's motion through the plastic?Hints: Fext T+MVi=MVf Ans: A. 9.09x10^-11s B.4.59x10^-10N

- A) d = Vavg * t 0.0025 m = ?(4.0 + 1.5)e7m/s * t t = 9.09e-11 s B) The hint uses the impulse equation: impulse + initial p = final p F * 9.09e-11s + 1.67e-27kg * 4.0e7m/s = 1.67e-27kg * 1.5e7m/s F = -4.59e-10 N Since the force is against the direction of motion, I think it should have a negative sign; your answer suggests it isn't warranted. Without the hint, you could do acceleration a = Δv / Δt = (1.5 - 4)e7 m/s / 9.09e-11s = -2.75e17 m/s? and then F = m*a = 1.67e-27kg * -2.75e17m/s? = -4.59e-10 N If you find this helpful, please award Best Answer!

- Q: For example, photographs, checks, receipts? I have a Brother MFC-3240C which works very well with large pieces of paper. Are there plastic envelopes or sheet holders that hold smaller items, so they can be passed through the sheet-feeder?

- I buy plastic sheets for a lot of uses. They come in letter page size. Very flat objects should be okay. But I have always used a flat bed scanner. It is also good when you want to copy something from a book or even artwork. These scanners can be had for $50.

Send your message to us

Plastic Sheets - 2024 New Fine White 4x8' 0.5mm Foam Sheet PVC for Factory Hot Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords