All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

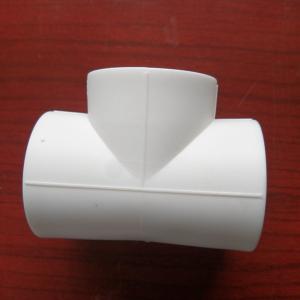

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Plastic Pipe FittingsView More

Plastic TubesView More

Plastic SheetsView More

Agricultural Plastic ProductsView More

Plastic NetsView More

Q & A

How can plastic products be cleaned?

Plastic products can be cleaned by using a mild soap or detergent and warm water. Gently scrubbing the surface with a soft cloth or sponge should remove most dirt and grime. For tougher stains, a mixture of baking soda and water can be used as a gentle abrasive. It is important to avoid using harsh chemicals or abrasive materials that can scratch or damage the plastic.

What are the most common uses of plastic products in the transportation sector?

Some of the most common uses of plastic products in the transportation sector include manufacturing of car interiors, such as dashboard components, door panels, and seat covers. Plastic is also used in the production of various exterior parts like bumpers, mirrors, and grilles. Additionally, plastic is widely used in the manufacturing of tires, fuel tanks, and various engine components.

How are plastic food wraps produced?

Plastic food wraps are produced through a process called extrusion. In this process, plastic pellets are melted and then forced through a die to form a thin, continuous sheet. The sheet is then cooled and wound onto large rolls, which can be later cut into smaller rolls or sheets for packaging. Various types of plastics, such as low-density polyethylene (LDPE), are commonly used to produce plastic food wraps.

Are plastic products safe for use with oily substances?

Plastic products are generally safe for use with oily substances. However, it is important to ensure that the plastic used is compatible with the specific type of oil being used. Some oils may react with certain types of plastic, causing degradation or leaching of harmful chemicals. Therefore, it is recommended to check the manufacturer's guidelines or use plastic products specifically designed for use with oily substances to ensure safety.

What are the different types of plastic bags?

There are several different types of plastic bags, including grocery bags, trash bags, ziplock bags, and poly bags used for packaging and shipping.

Wholesale Plastic Products from supplier in Mexico

Whether you are looking for plastic raw materials, packaging solutions, or finished plastic products, we have you covered. Our product range includes but is not limited to:

1. Plastic Resins: We supply a wide range of plastic resins, including polyethylene, polypropylene, polystyrene, polyvinyl chloride, and more. Our resins are sourced from reputable manufacturers and can be tailored to meet your specific requirements.

2. Packaging Solutions: We offer a variety of plastic packaging solutions, such as bottles, containers, bags, and films. Our packaging solutions are designed to meet industry standards and are available in various sizes, shapes, and colors.

3. Plastic Additives: We provide a range of plastic additives, including colorants, stabilizers, fillers, and lubricants. These additives can enhance the performance and appearance of your plastic products.

4. Plastic Machinery: We offer a selection of plastic machinery, including injection molding machines, extruders, blow molding machines, and auxiliary equipment. Our machinery is sourced from renowned manufacturers and can be customized to meet your production requirements.

5. Custom Plastic Products: If you require custom plastic products, our experienced team can assist you in product design, prototyping, and manufacturing. We have the expertise and resources to bring your ideas to life.

In addition to our extensive product portfolio, we also provide a range of services to support your projects in Mexico. These include logistics and transportation, quality control, technical support, and after-sales service. We understand the importance of timely delivery and product quality, and we strive to exceed your expectations in these areas.

Contact us today to discuss your Plastic Products needs in Mexico. Our dedicated team is ready to assist you and provide the best solutions for your business.

1. Plastic Resins: We supply a wide range of plastic resins, including polyethylene, polypropylene, polystyrene, polyvinyl chloride, and more. Our resins are sourced from reputable manufacturers and can be tailored to meet your specific requirements.

2. Packaging Solutions: We offer a variety of plastic packaging solutions, such as bottles, containers, bags, and films. Our packaging solutions are designed to meet industry standards and are available in various sizes, shapes, and colors.

3. Plastic Additives: We provide a range of plastic additives, including colorants, stabilizers, fillers, and lubricants. These additives can enhance the performance and appearance of your plastic products.

4. Plastic Machinery: We offer a selection of plastic machinery, including injection molding machines, extruders, blow molding machines, and auxiliary equipment. Our machinery is sourced from renowned manufacturers and can be customized to meet your production requirements.

5. Custom Plastic Products: If you require custom plastic products, our experienced team can assist you in product design, prototyping, and manufacturing. We have the expertise and resources to bring your ideas to life.

In addition to our extensive product portfolio, we also provide a range of services to support your projects in Mexico. These include logistics and transportation, quality control, technical support, and after-sales service. We understand the importance of timely delivery and product quality, and we strive to exceed your expectations in these areas.

Contact us today to discuss your Plastic Products needs in Mexico. Our dedicated team is ready to assist you and provide the best solutions for your business.