All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the historical evolution of aluminum foil production and its earliest industrial uses?

The historical evolution of aluminum foil production dates back to the late 19th century when aluminum, a relatively new metal, was discovered and commercially produced. In 1888, Charles Martin Hall and Paul Héroult independently developed the Hall-Héroult process, which allowed for the extraction of aluminum from its ore on an industrial scale. This breakthrough led to the beginning of commercial aluminum production.

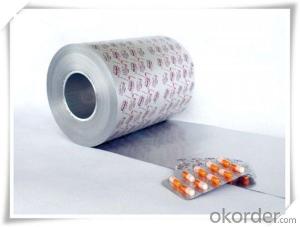

The first industrial use of aluminum foil emerged in the early 20th century. In 1910, the Swiss chemist Dr. Lauber invented a rolling process that enabled the production of thin aluminum sheets. This development paved the way for the creation of aluminum foil, which was initially used primarily for packaging purposes. Its properties, such as being lightweight, flexible, and a good barrier against moisture and oxygen, made it an ideal material for packaging perishable goods like food and pharmaceutical products.

During World War II, aluminum foil played a crucial role in military applications. It was used for insulation in aircraft, as a protective covering for military equipment, and even as a component in radar technology. Its versatility, combined with its lightness and durability, made it an essential material in various military operations.

In the post-war era, aluminum foil production and usage expanded rapidly. The development of continuous rolling mills allowed for more efficient production methods, making aluminum foil more readily available and affordable. Its applications expanded beyond packaging to include cooking, where it became widely used for wrapping and preserving food. The ability to withstand high temperatures and distribute heat evenly made aluminum foil a staple in kitchens worldwide.

Today, aluminum foil is used in a wide range of industries and applications. It is still widely used for packaging, both in consumer goods and pharmaceuticals. Additionally, it is utilized in insulation, electrical applications, automotive components, and even in the construction sector. The historical evolution of aluminum foil production and its earliest industrial uses demonstrate its remarkable versatility and durability, contributing to its continued popularity and widespread usage in modern times.

Can aluminum foil be employed to build a temporary ice shelter for winter activities?

Yes, aluminum foil can be used to build a temporary ice shelter for winter activities.

How can you safely store aluminum foil in the kitchen?

To safely store aluminum foil in the kitchen, it is recommended to keep it in a cool and dry place, away from heat sources or direct sunlight. It should be stored in its original packaging or transferred to an airtight container or ziplock bag to prevent it from getting damaged or contaminated. Additionally, it is advisable to keep it away from other sharp or heavy objects to avoid punctures or tears.

Wholesale Aluminum Foils from supplier in Mexico

We are a Aluminum Foils supplier serving the Mexico, mainly engaged in the sale, quotation, and technical support services of various Aluminum Foils products in the Mexico region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Foils procurement services in the Mexico. Not only do we have a wide range of Aluminum Foils products, but after years of market development in the Mexico, we can also provide valuable experience for your projects.