4X8 Styrofoam Sheets

4X8 Styrofoam Sheets Related Searches

4 X 8 Styrofoam Sheets 4 Inch Styrofoam Sheets Stainless Steel 4x8 Sheets Stainless Steel Sheets 4x8 4x8 Stainless Steel Sheet Plastic Sheets 4X8 Stainless Steel 4x8 Sheet 4X8 Tin Sheets Hard Plastic Sheets 4X8 4x8 Sheet Of Stainless Steel Plexiglass Sheets 4X8 Polypropylene Sheets 4X8 4X8 Metal Sheets 4 X 8 Tin Sheets 4 X 8 Sheet Of Stainless Steel Clear Plastic Sheets 4X8 4 By 8 Plastic Sheets 8 X 4 6Mm Plywood Sheets 4X8 Sheet Aluminum 4 Inch Foam Sheet 4X10 Plywood Sheets 2 Inch Styrofoam Insulation Sheets 3Mm Plywood Sheets 8X4 6 X 8 Plywood Sheet 4X12 Plywood Sheets Sheet Metal Sheets 4X8 4x8 Stainless Steel Sheet Price 8 X 4 Foam Board 6 X 4 Plywood Sheets Diamond Plate Aluminum Sheets 4X84X8 Styrofoam Sheets Supplier & Manufacturer from China

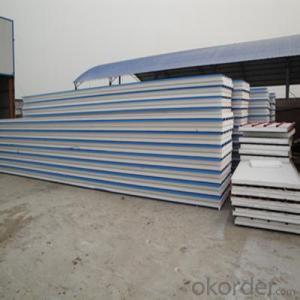

4X8 Styrofoam Sheets are a type of insulation material made from expanded polystyrene, known for its lightweight properties and excellent thermal insulation capabilities. These sheets are commonly used in various industries, including construction, packaging, and art and craft projects. They provide an effective solution for insulation, soundproofing, and protection against external elements, making them a versatile choice for numerous applications.The 4X8 Styrofoam Sheets are widely used in construction for insulating walls, roofs, and floors, as well as in the creation of lightweight structures. In the packaging industry, these sheets serve as protective packaging materials, cushioning fragile items during transportation. Additionally, they are popular in art and craft projects, where they can be easily cut and shaped to create various designs and sculptures. Their versatility and affordability make them a preferred choice for both commercial and personal use.

Okorder.com is a leading wholesale supplier of 4X8 Styrofoam Sheets, offering a vast inventory of high-quality products at competitive prices. With a commitment to customer satisfaction, Okorder.com ensures that their products meet the highest standards of quality and performance. By partnering with Okorder.com, customers can access a reliable source for 4X8 Styrofoam Sheets, catering to their various needs across different industries.

Hot Products