4 X 8 Film Faced Plywood Sheets for Construction Formwork

- Ref Price:

-

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 3000 m³/month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Specification

Type:

Film Faced Plywood

Application:

For Construction

Packaging & Delivery

| Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

|---|

| Delivery Detail: | 30days after receiving LC or deposit |

|---|

Specifications

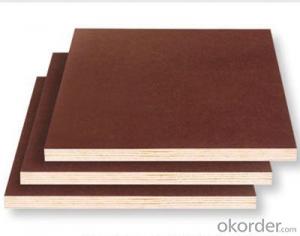

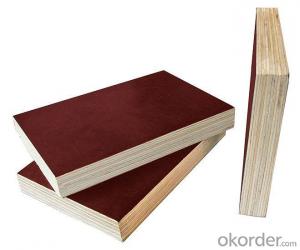

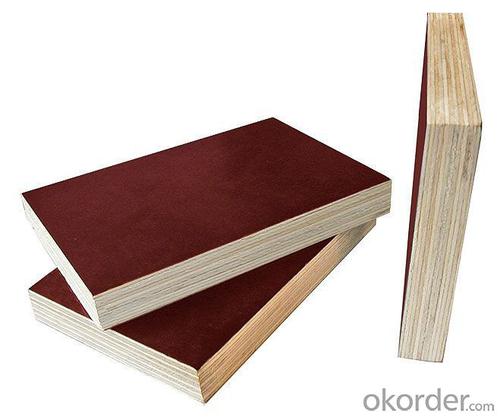

film faced plywood

1)size:1220x2440mm

2)F/B:brown,black,red

3)core:poplar,combi,hardwood

4)glue:WBP,melamine,MR

Product Name | Film faced plywood |

F/B | Black film, brown film, anti-slip film |

Grade | First grade |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | MR WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm, |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 15 days after order confirmed |

Supply Capacity | 3000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce techniqueCredit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result |

1 | Moisture content | % | EN322 | 8-12 | Check out |

2 | Density | Kg/m3 | EN322 | 560 | Check out |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.72 Min:0.85 | Check out |

Damage rate | % | GB/T17656-1999 | 60% |

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 6800 | Check out |

Lateral | 5920 |

5 | Bending strength(N/mm) | Longitudinal | 63 | Check out |

Lateral | 48 |

6 | Cycle Life | About 12-25 repeated using times according projects by formwork application

|

- Q: Plywood in the material defects?

- Abnormal structure Any defects caused by abnormal wood construction, such as wrinkles. Wavy pattern. Staggered pattern, spiral pattern and so on.

- Q: What does plywood mean and its synthesis?

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q: Plywood can improve timber utilization and is a major way to save wood.

- Also available for aircraft, ships, trains, cars, construction and crates and other materials.

- Q: Contemporary plywood market development

- as well as foreign high-quality hardwood wood constantly added for the Chinese plywood industry's continuous development To provide a wealth of raw materials; adequate human resources,

- Q: A brief introduction to plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q: What is the density of plywood?

- Plywood can improve timber utilization and is a major way to save wood

- Q: What are the advantages and disadvantages of plywood?

- and then made of adhesive glue from the three or more layers of plate-like material

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- and the dashboard and the inner panel are arranged symmetrically on both sides of the center layer or the core.

- Q: Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer