Anti-slip Film Faced Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 10000 CBM per month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

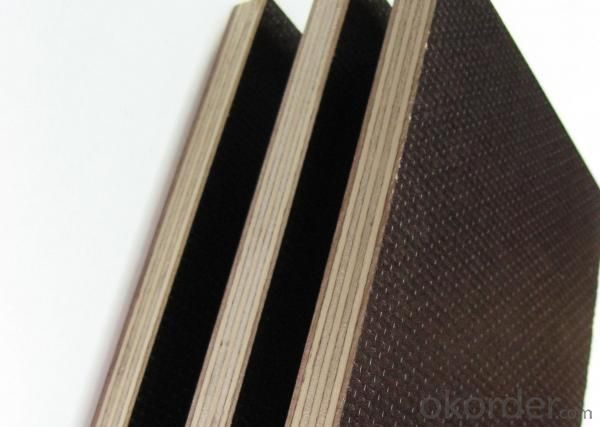

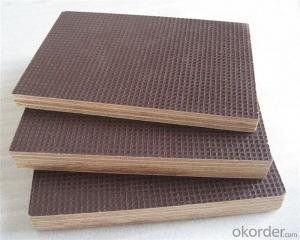

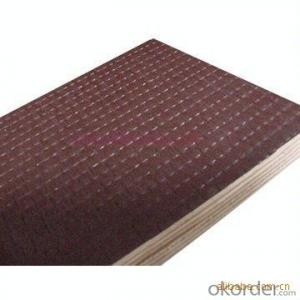

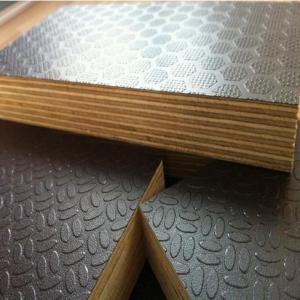

Specifications of Anti-slip Film Faced Plywood

1) Size: 1220×2440mm, 1250×2500mm,1500×3000mm,1525×3500mm, or as request

2) Thickness: 4-100mm

3) Glue: MR, Melamine,WBP Core: Poplar, Birch, Pine, Hardwood,etc

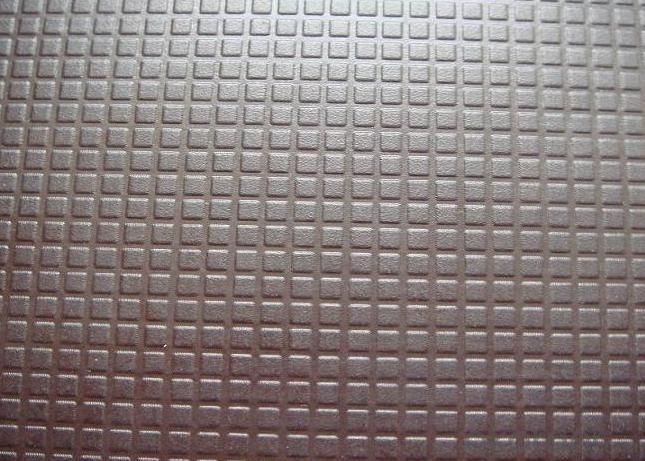

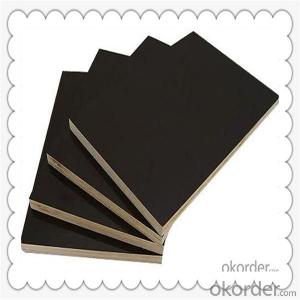

4) Surface: Imported Brown/Black Film; Chinese Brwon/Black Film

5) Anti-slip Pattern: Square, Hexa grip, etc

6) Special Treatment: Bevel, Tongue & Groove,Punch, etc

7) Moisture Content: 8-14%

8) Application: Concrete forming, Platform, Cassette Systems and Trailer Flooring, etc.

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Advantage of Anti-slip Film Faced Plywood

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: The structure of the plywood at the same time meet two basic principles

- the fiber direction and the table are parallel to the long core plate or the middle plate. When forming a slab, the panel and the backplate must face outward.

- Q: How to use building plywood?

- in the decoration works mainly used in ceilings, wall skirts, floor linings and so on.

- Q: Multilayer board and plywood difference

- The multilayer board is usually arranged symmetrically on both sides of the center or core.

- Q: The Preparation of plywood ingredients

- core core core sandwich panel or composite plywood center layer. Usually its thickness is greater than the other layers.

- Q: What are the defects in plywood material?

- Fracture split, end split The fiber is separated in the direction of the grain, usually starting from one end and extending through the thickness of the morning plate

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: What is a joinery board?

- Blockboard core board should be the same species or similar properties of the tree species, water content of 6 to 12%. Core width is not greater than three times the thickness, do not allow a larger crack, holes and so on

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- and the dashboard and the inner panel are arranged symmetrically on both sides of the center layer or the core.

- Q: One of the commonly used materials for furniture is a wood-based panel

- usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

Send your message to us

Anti-slip Film Faced Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 10000 CBM per month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords